Flooded type water cooled screw chiller (PCB Control) MCAC-CTSM-2012-11

61

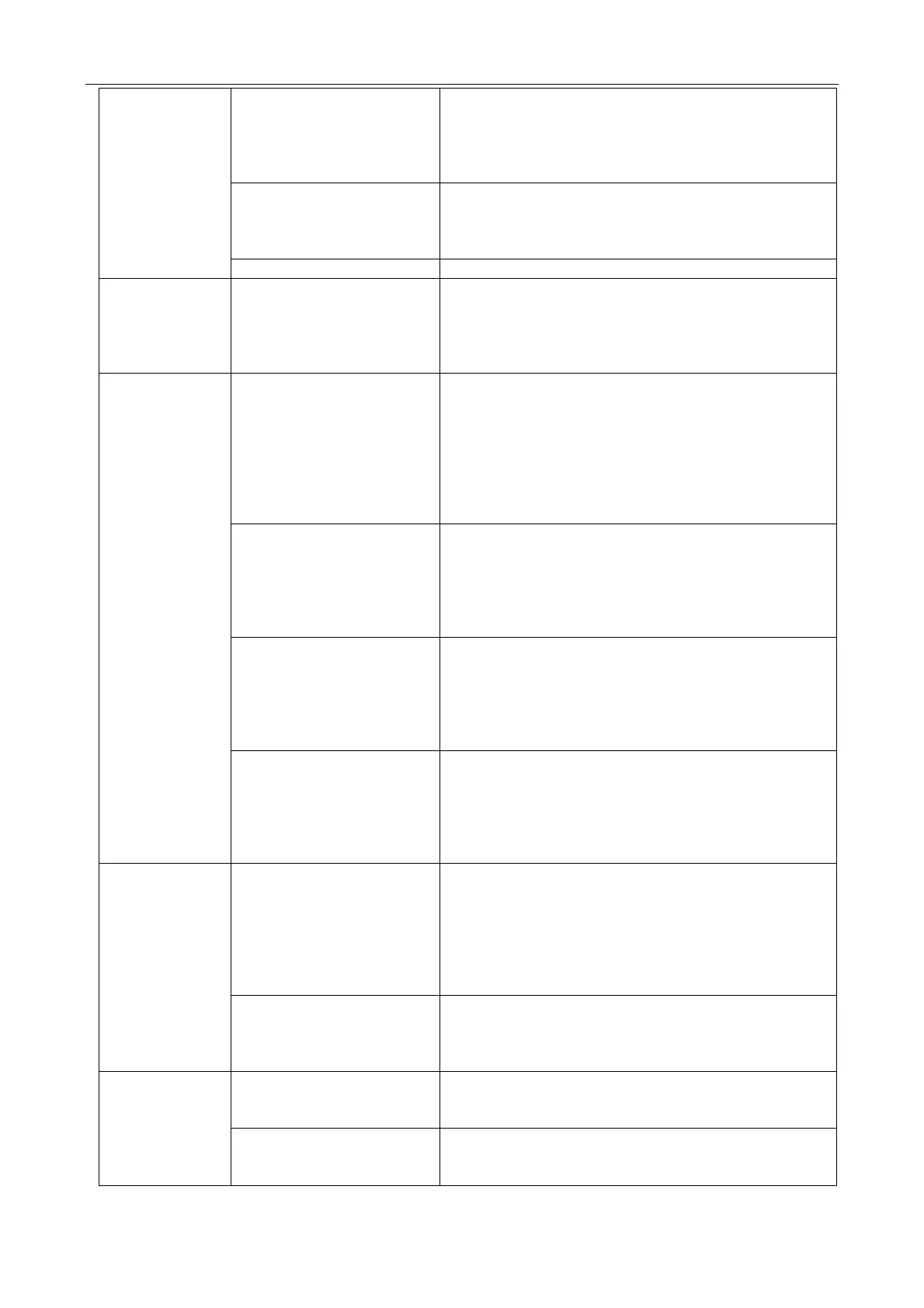

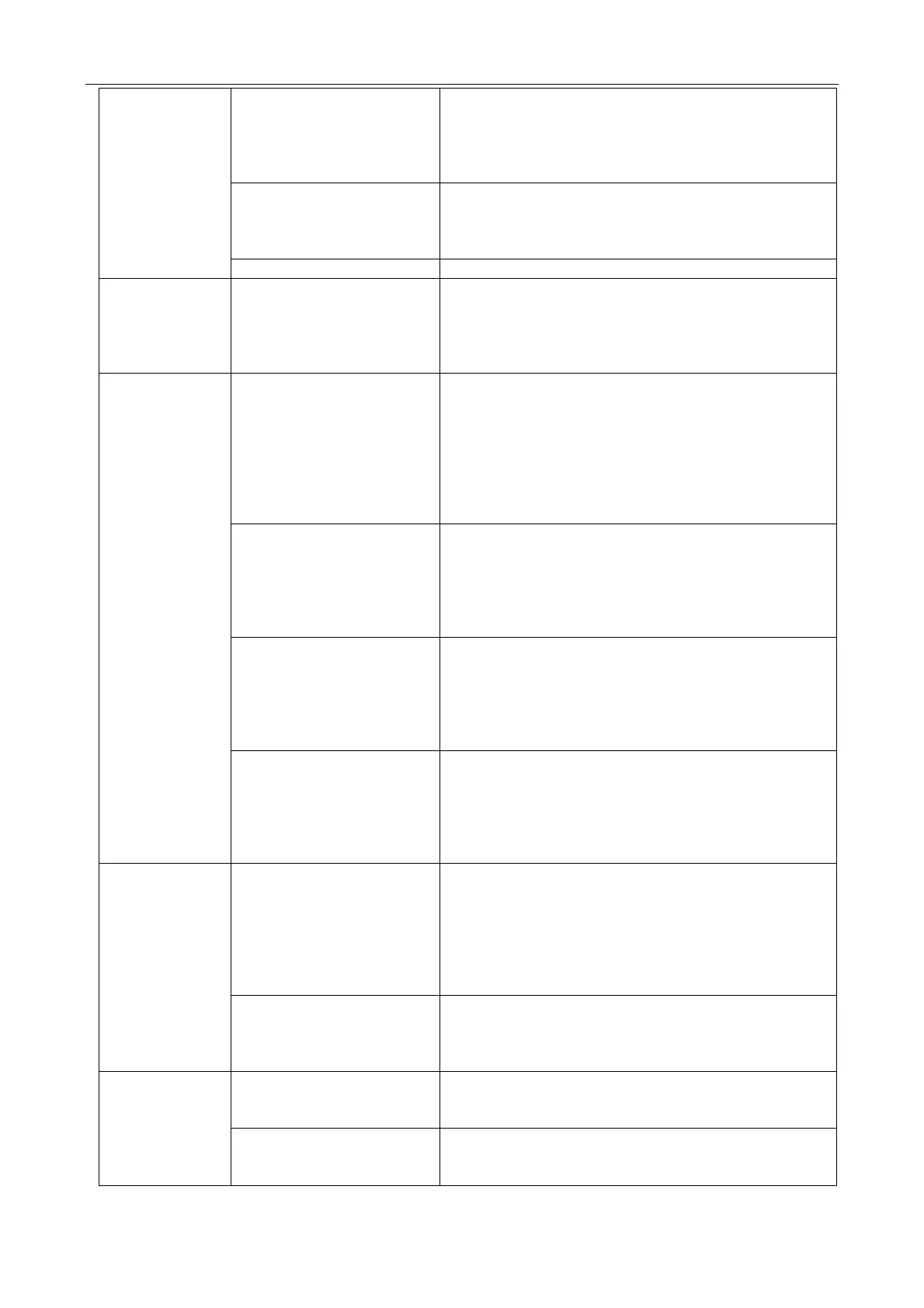

degree of superheat

temperature is not low, but

there is still liquid flows

back to the compressor

unit

can be closed: the proportion coefficient increases to

30, integral time increased to 250 seconds,

differential time increased to 10 seconds

A plurality of refrigerator

and defrosting

Stagger the defrosting start time. If unable to stagger,

in the absence of the first two issues in the case, will

involve the refrigerated cabinet superheat setpoint

and at least 2 °C LowSH threshold increase

The valve is too large The replacement for the smaller valves

Liquid only at

start controller

(closed) when

returning to the

compressor

Parameter "start control

valve opening degree" set

too high

Reference to the evaporator cooling capacity and

rated capacity of the valve than check this parameter

value; necessary to reduce this value

Superheat

value is about

swing around

the set value,

and larger than

4 ° C

Condensing pressure

instability

Check the controller condenser settings, set the

parameter to the more "moderate" values (such as

increasing the proportion with or increasing the

integration time). Note: the need for stability,

including + / -0.5 bar changes. If this does not work

or can not change the settings,In the "oscillation"

system used in electronic expansion valve control

parameters

Even if the valve is set to

manual control (mean

value in the corresponding

position with the work), the

value remains stable

superheat

Check the cause of instability (such as the refrigerant

charge is less) and try to solve.

If not feasible, in the "oscillation" system used in the

electronic expansion valve control parameters

Will set the manual control

valve (in the position

corresponding to the

average work), the

superheat value is no

longer swing

First try to reduce the scale factor (30% to 50%) and

then increasing the integration time by the same

proportion. In any case, the recommended use of

stable system parameters

Superheat setting is too

low

Increase the superheat setting, check to make sure

superheat swing has been reduced or disappeared.

Set the start of 13 ° C,and then gradually reduce the

set value, to ensure that the system does not swing

again and the device temperature can be set to

control value

In the

evaporating

temperature

higher start-up

phase, the

evaporation

pressure is too

high

MOP protection disabled

or invalid

The MOP threshold is set to require saturated

evaporation temperature (high evaporation

temperature limit compressor) and MOP integration

time set between the National Cheng Kung

University in 0 (recommended for 4 seconds) to

activate the MOP protection. To make the protection

more sensitive, down MOP integration time low

Start system or transient

conditions, excess

refrigerant charge (for

refrigerator)

A "soft start", a time to start a facility or a group. If this

method is not feasible to reduce all the facilities of

the MOP threshold

Low start-up

phase

protection

function

activated (only

comes with the

Parameter "start control

valve opening degree" set

too low

Reference to the evaporator cooling capacity and

rated capacity of the valve than check this parameter

value; increase this value if necessary

tLAN or pLAN drive

configured not begin to

control the valve remains

Check tLAN / pLAN wiring. Check that the drive to

connect with the pCO application (if equipped)

properly manage the drive start signal. Check that

Loading...

Loading...