Flooded type water cooled screw chiller (PCB Control) MCAC-CTSM-2012-11

62

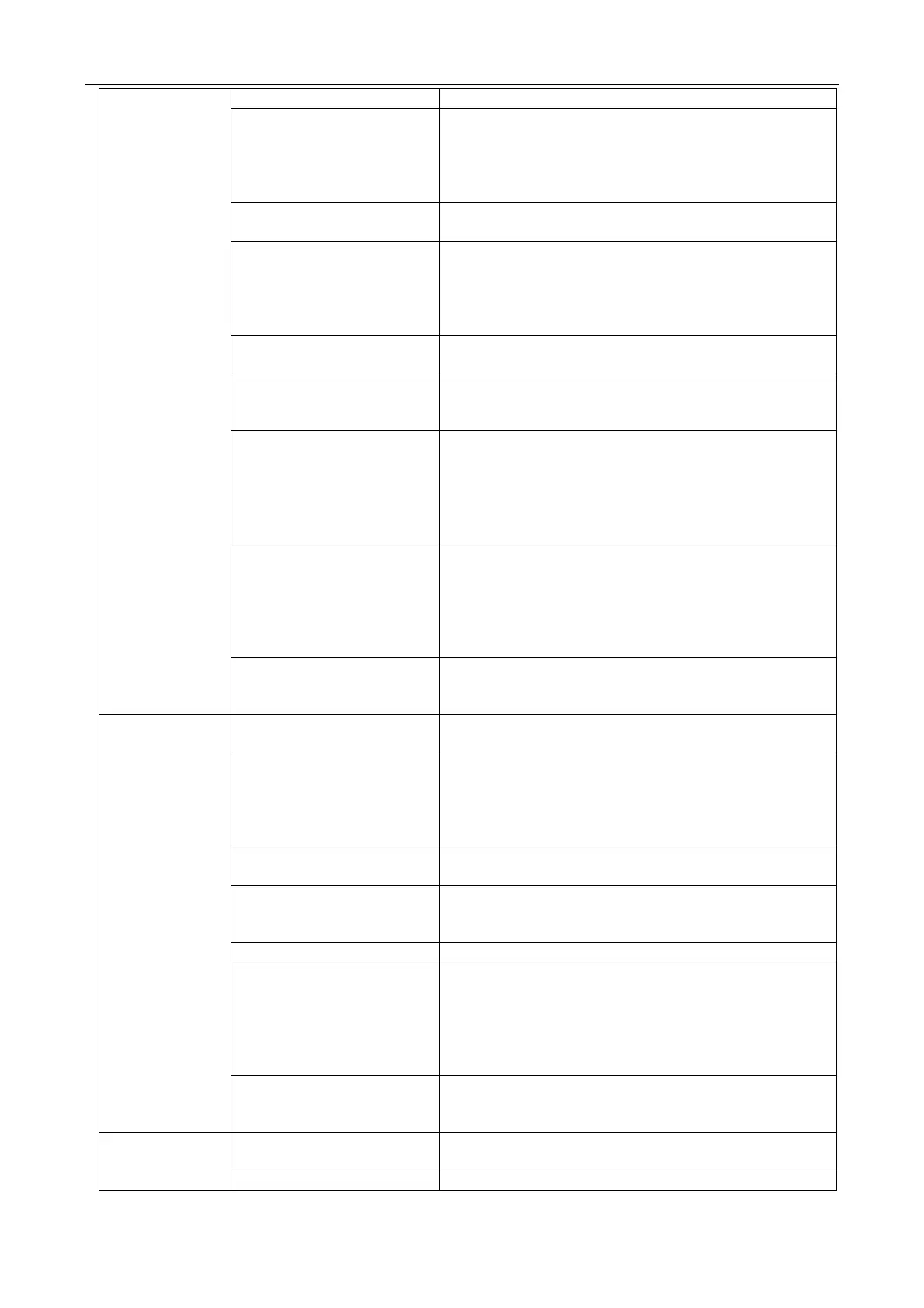

compressor

equipment)

closed the drive is not in standalone mode

Configured as a

stand-alone mode, the

drive does not begin to

control the valve remains

closed

Check the digital input terminal. Check that when the

control signal input correctly when closed. Check

that the drive is in stand-alone mode

LOP protection disabled The LOP integration time is set to greater than 0

seconds

LOP protection invalid Ensure that the needs of the LOP protection

threshold in the saturation temperature of

evaporation (evaporation temperature and the rated

voltage corresponding to the temperature scale

switch between) and reduce the LOP integration time

Solenoid valve block Check the solenoid valve opens correctly, check the

electrical wiring and relay operation

Lack of refrigerant Check expansion valve upstream of the observation

hole no bubbles. To ensure proper cooling

temperature (greater than 5 ° C); or refrigerant filling

Valve connection error

(rotation in the opposite

direction) and is open

And manual control valve is completely closed or

open, to check the valve rotation. Once the valve is

fully open to allow heat decreased, and vice versa so

that the superheat values have increased. If the

valve is rotating in the opposite direction, check the

electrical wiring

Valves damaged or

connected incorrectly the

stator

The stator and the valve and disconnect the cable

connection, with ordinary measuring coil resistance

tester.

Two coil resistance should be around 36 Euro.

Otherwise, replace the stator. Finally, check the

cable connection to connect the drive

Valve can not open Started using the manual control valve fully open. If

the superheat value is still high, check the electrical

wiring and / or replace the valve

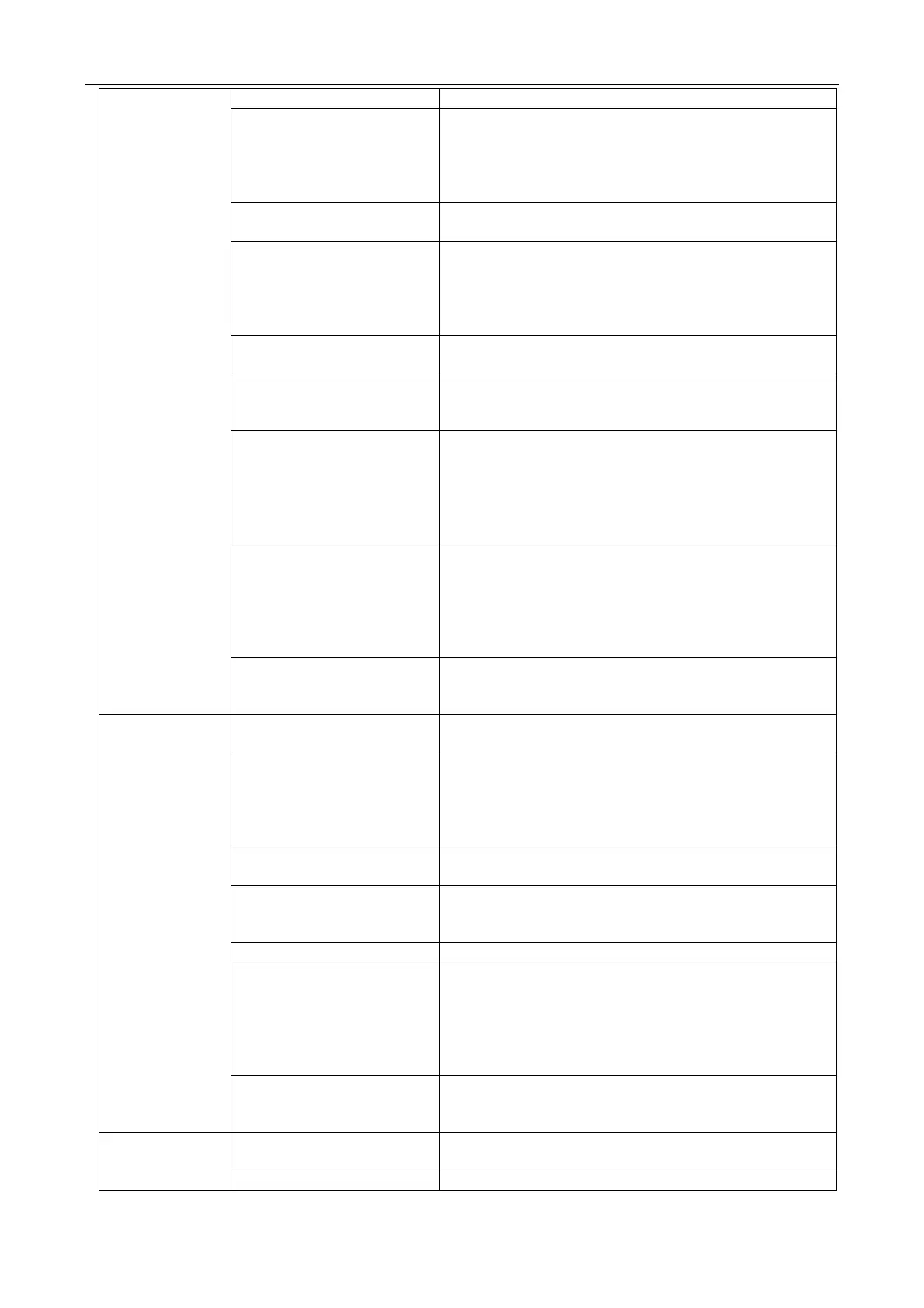

Control process

equipment due

to low and off

(only comes

with the

compressor

equipment)

LOP protection disabled The LOP integration time is set to greater than 0

seconds

LOP protection invalid Ensure that the needs of the LOP protection

threshold in the saturation temperature of

evaporation (evaporation temperature and the rated

voltage corresponding to the temperature scale

switch between) and reduce the LOP integration time

Solenoid valve block Check the solenoid valve opens correctly, check the

electrical wiring and relay operation

Lack of refrigerant Check expansion valve upstream of the observation

hole no bubbles. To ensure proper cooling

temperature (greater than 5 ° C); or refrigerant filling

Valve is too small Replaced with a larger valve

Valves damaged or

connected incorrectly the

stator

The stator and the valve and disconnect the cable

connection, with ordinary measuring coil resistance

tester.

Two coil resistance should be around 36 Euro.

Otherwise, replace the stator. Finally, check the

cable connection to connect the drive

Valve can not open Started using the manual control valve fully open. If

the superheat value is still high, check the electrical

wiring and / or replace the valve

Even if the

valve is fully

opened,

Solenoid valve block Check the solenoid valve opens correctly, check the

electrical wiring and relay operation

Lack of refrigerant Check expansion valve upstream of the observation

Loading...

Loading...