MCAC-VTSM-2015-09 R410A All DC Inverter V4+S Series 60Hz

Installation 99

4.2 Storage and maintenance of copper pipe

4.2.1 Pipe delivery and storage

1. Prevent bending or deforming during the delivery.

2. Seal the openings of the copper pipe with a plug or adhesive tape during the storage.

3. Place the coil upright to avoid compressing deformation due to self-weight.

4. Use wooden support to ensure that the copper pipe is higher than the ground, so as to make the pipe

dust-proof and water-proof.

5. Take dust-proof and water-proof measures at both ends of the pipe.

6. Store piping at a at specified place on the construction site.

4.2.2 Correct to seal the opening

1. There are two ways for opening sealing:

1) Sealing with cover or adhesive tape (suitable for short-term storage)

2) Wielding seal (suitable for long-term storage)

Caution: The openings of the copper pipe must be sealed at all times during construction.

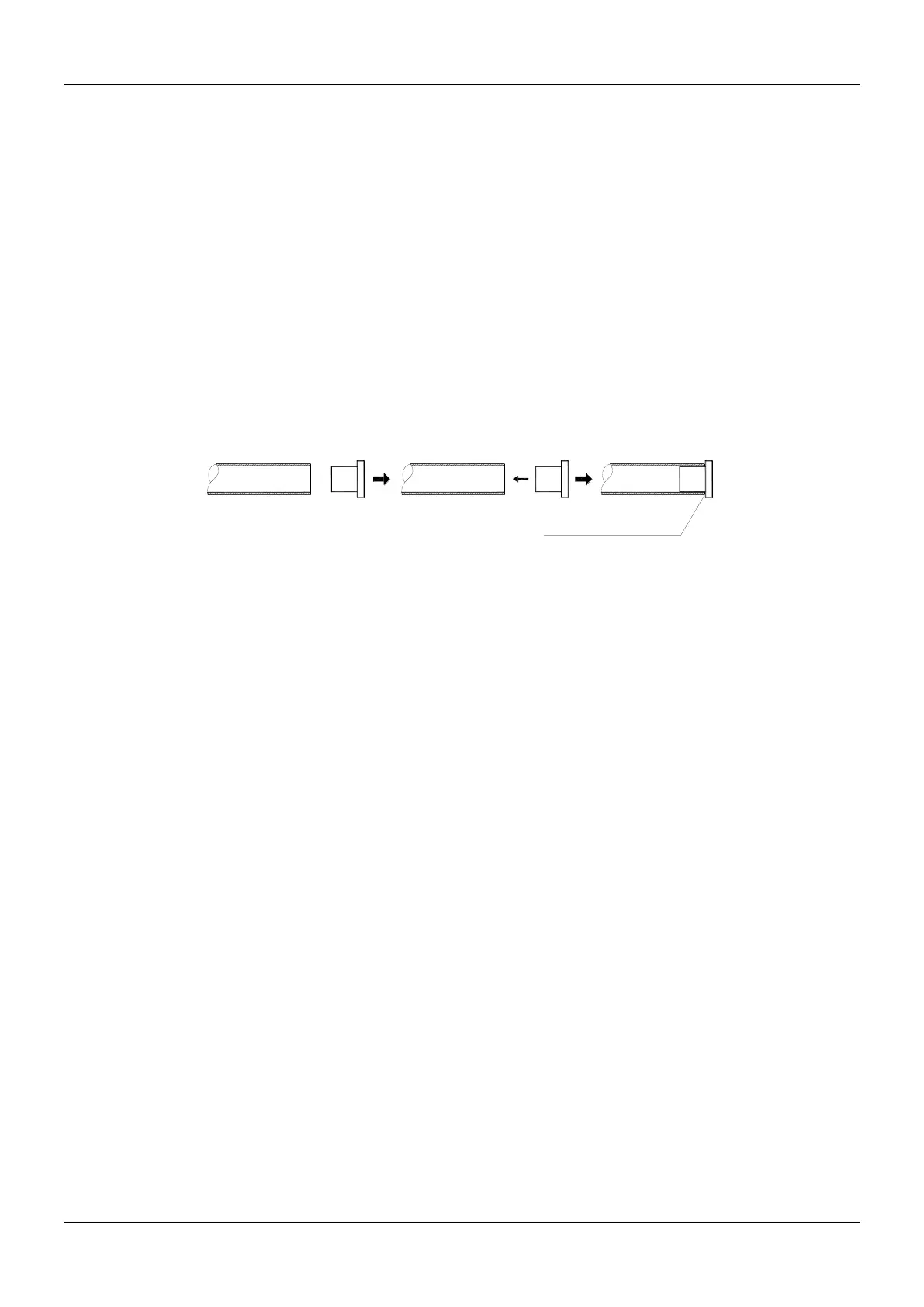

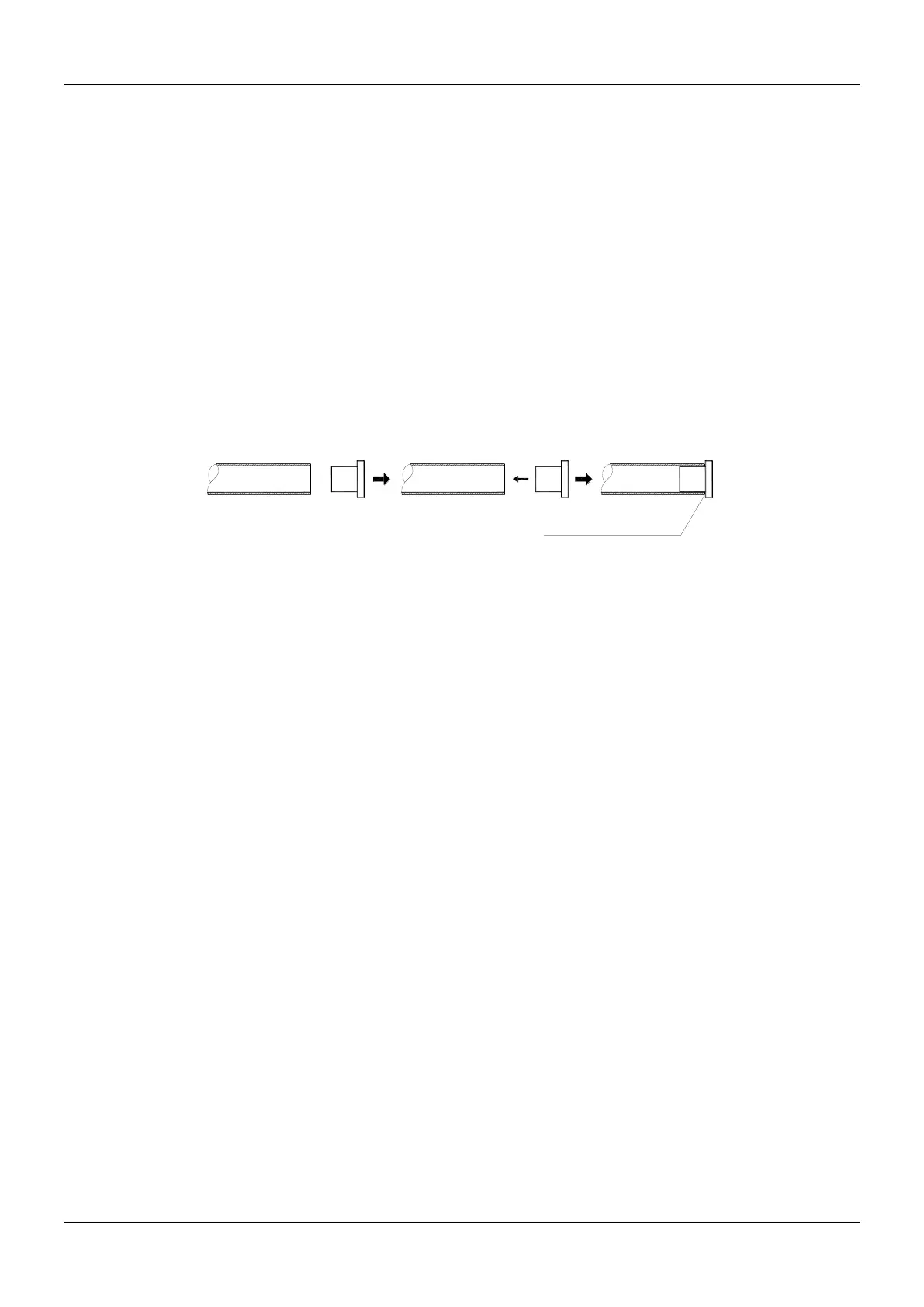

● Method of sealing with cover or adhesive tape

Copper pipe

Cover

Insert

Use adhesive tape to

twist tightly at the joint

It is recommended to seal the openings of the pipe with both cover and adhesive tape.

● Wielding seal method

2. Attention:

1) When putting the copper pipe through the hole in the wall, dirt can easily enter into the pipe, the pipe orifice

should be sealed.

2) When the copper pipe is placed outside a wall, ensure that no rain water can enter the pipe, particularly

when the pipe is placed upright.

3) Before completing the pipe connection, seal the openings of the pipe with covers.

4) Place the openings of the pipe vertically or horizontally.

5) Before putting the pipe outside the wall, seal the opening of the pipe with a cover.

6) Do not place the pipe directly on the ground, or keep it away from ground friction.

7) If piping on a raining day, remember to seal the openings of the pipe first.

4.3 Processing of copper pipe

4.3.1 Pipe cutting

1. Tool

Use a pipe cutter instead of a saw or cutting machine to cut the pipe.

2. Correct operation procedure:

Rotate the pipe evenly and slowly, and apply even force to it. Cut the pipe off while ensuring that it does not

become deformed.

3. Risks if a saw or cutting machine is used to cut pipe:

Copper shavings will enter the pipe, these particles are difficult to remove and pose a serious risk to the

system if they enter the compressor or block the throttling unit.

4.3.2 Rectify opening of copper pipe

1. Purpose

To shave away any burrs at the opening of the copper pipe, clean the inside of the pipe, and rectify the

opening of the pipe, so as to avoid scratches at the opening to be sealed during flaring.

2. Operation procedure

1) Use a scraper to remove the inner spurs. When doing so, keep the opening of the pipe downwards to avoid

Loading...

Loading...