V4+R VRF 50/60Hz

201608 91

Part 5 - Diagnosis and Troubleshooting

Step 5: Check filters(s)

If the oil from a compressor is spoiled (lightly or heavily), check the filter between the gas stop valve and the 4-way

valve in that unit. If it is blocked, clean with nitrogen or replace.

Step 6: Replace the faulty compressor and re-fit the other compressors

Replace the faulty compressor.

If the oil had been spoiled and was drained from the non-faulty compressors

in Step 3, use clean oil to clean them before re-fitting them into the units. To

clean, add oil into the compressor through the discharge pipe using a funnel,

shake the compressor, and then drain the oil. Repeat several times and then

re-fit the compressors into the units. (The discharge pipe is connected to the

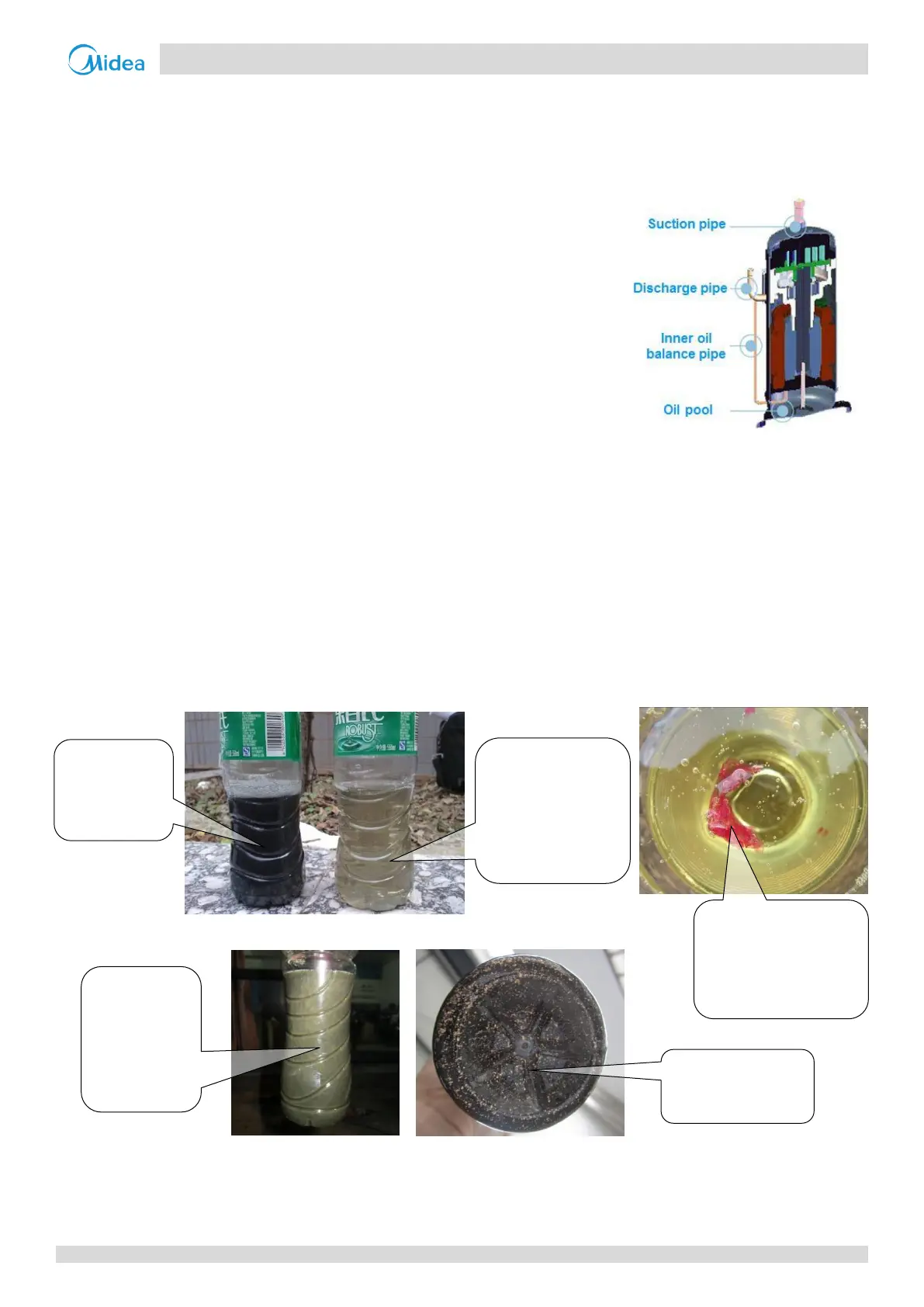

oil pool of the compressor by the inner oil balance pipe. Refer to Figure

5-4.15.)

Step 7: Add compressor oil

Add 1.2L of oil to the new compressor through the discharge pipe, using a funnel.

Add 1.2L of oil to each of the compressors from which oil was drained in Step 3.

Only use FV68H oil. Different compressors require different types of oil. Using the wrong type of oil leads to various

problems.

Add additional oil to the accumulators such that the total amount of oil is 5L in 8-12HP units and 7L in 14-22HP units.

Step 8: Vacuum drying and refrigerant charging

Once all the compressors and other components have been fully connected, vacuum dry the system and recharge

refrigerant. Refer to the V5 X Engineering Data Book, Part 3.

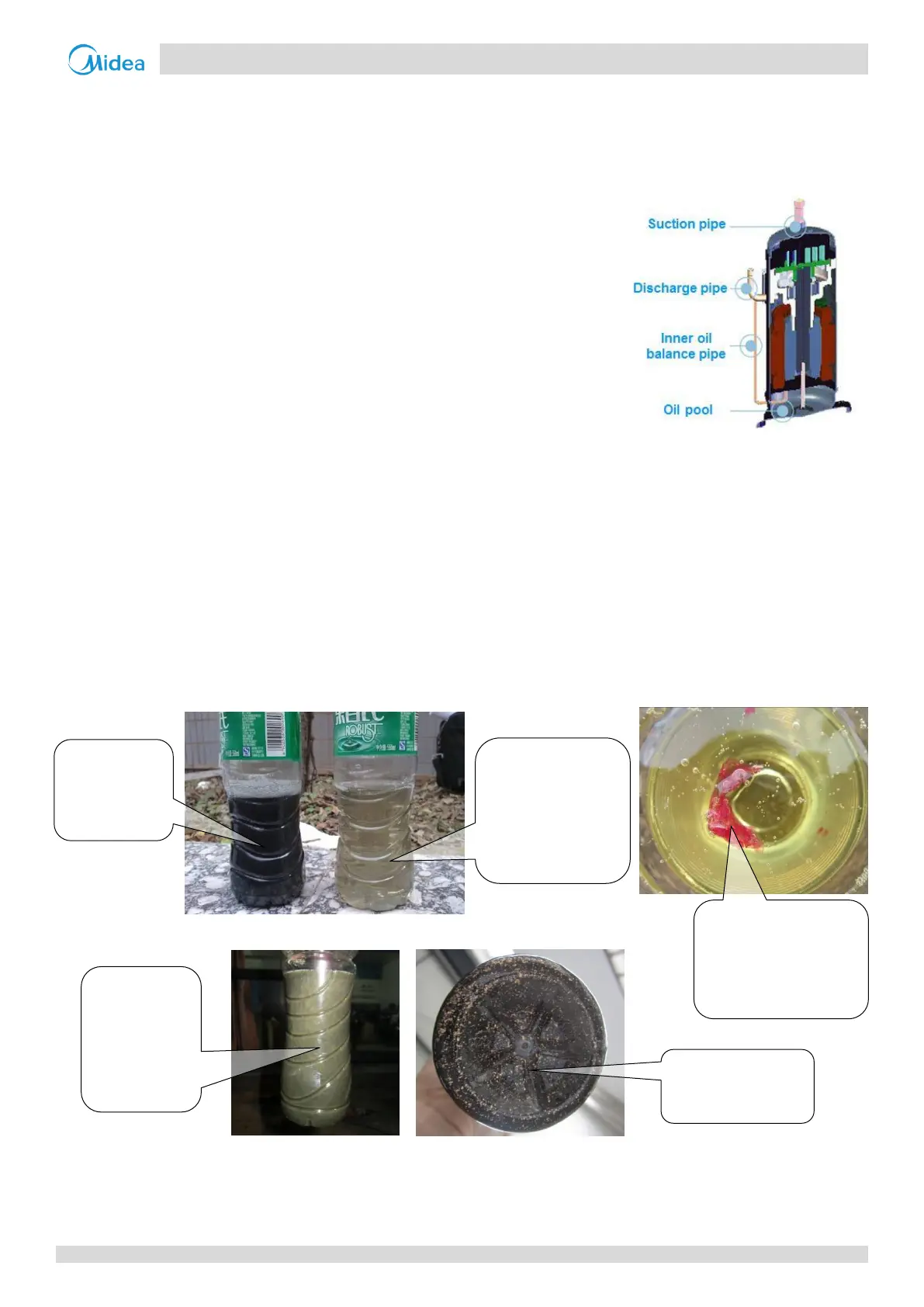

Figure 5-4.16: Inspecting compressor oil

Figure 5-4.15: Compressor piping

This oil is black

- it has been

yellow, but is clear

and transparent and

the condition is

transparent but there

are impurities which

oil indicates

abnormal

system

This oil contains

Loading...

Loading...