www.roadwidener.com

24

Model SP-8 &10

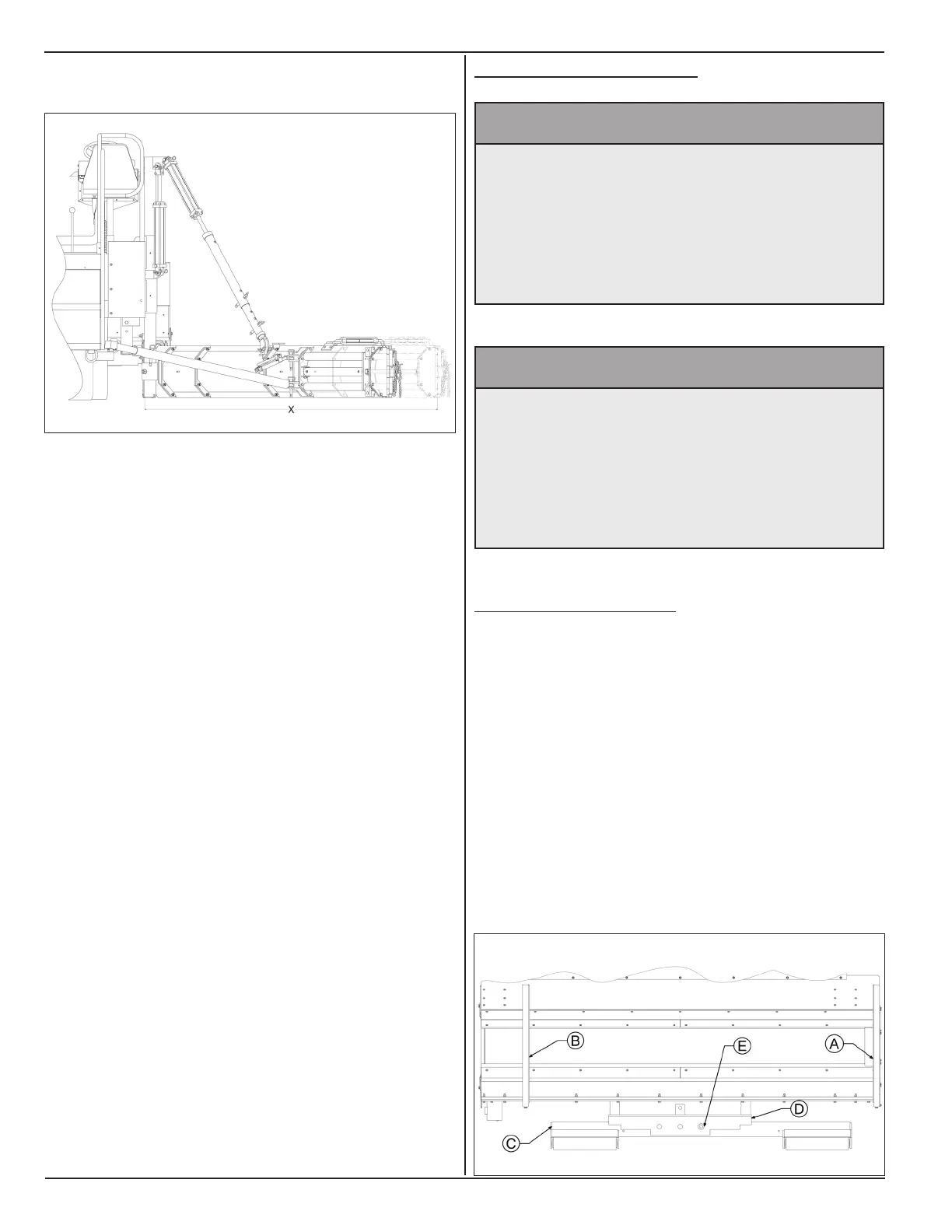

Following illustration shows different combinations of

blade sections with hydraulic extension.

Dimension X: 7 - 8.5 Ft Blade

• (1) - Pivot Section

• (2) - 1 Ft Section

• (1) - 2 Ft Section

• (1) - 2 - 3.5 Ft* Hydraulic Extension

* Projected stroke length at 45° Paving Angle.

Dimension X: 4 - 5.5 Ft Blade

• (1) - Pivot Section

• (1) - 1 Ft Section

• (1) - 2 - 3.5 Ft* Hydraulic Extension

* Projected stroke length at 45° Paving Angle.

10. Reinstall blade push tube anchor (G) at

approximately ½ to ⅔ of blade length. Reinstall

blade slope mount (F) at approximately ⅔ of blade

length. Use suitable hardware.

11. Reinstall slope tubes, push tubes and set up paving

and slope angles as in section 5.3.1.

12. Start engine, check operation and check for leaks.

Paving width can also be varied by adjusting the push

tubes and changing the blade paving angle. While

changing the blade paving angle material ow must be

taken into consideration. Depending on material ow, a

greater blade angle may be needed to ll entire spread

width. Narrow spread widths do not require as much

blade angle.

5.4 pusH roller setup

^ WARNING

Prevent serious injury or death.

Do not pull out push roller beyond 6th

hole.

Push roller assembly may fall out of tubes

and cause serious injury.

^ WARNING

Prevent serious injury or death.

Use caution while taking pivot pin out of

the push roller mount.

Push roller beam may fall out of push roller

mount and cause serious injury.

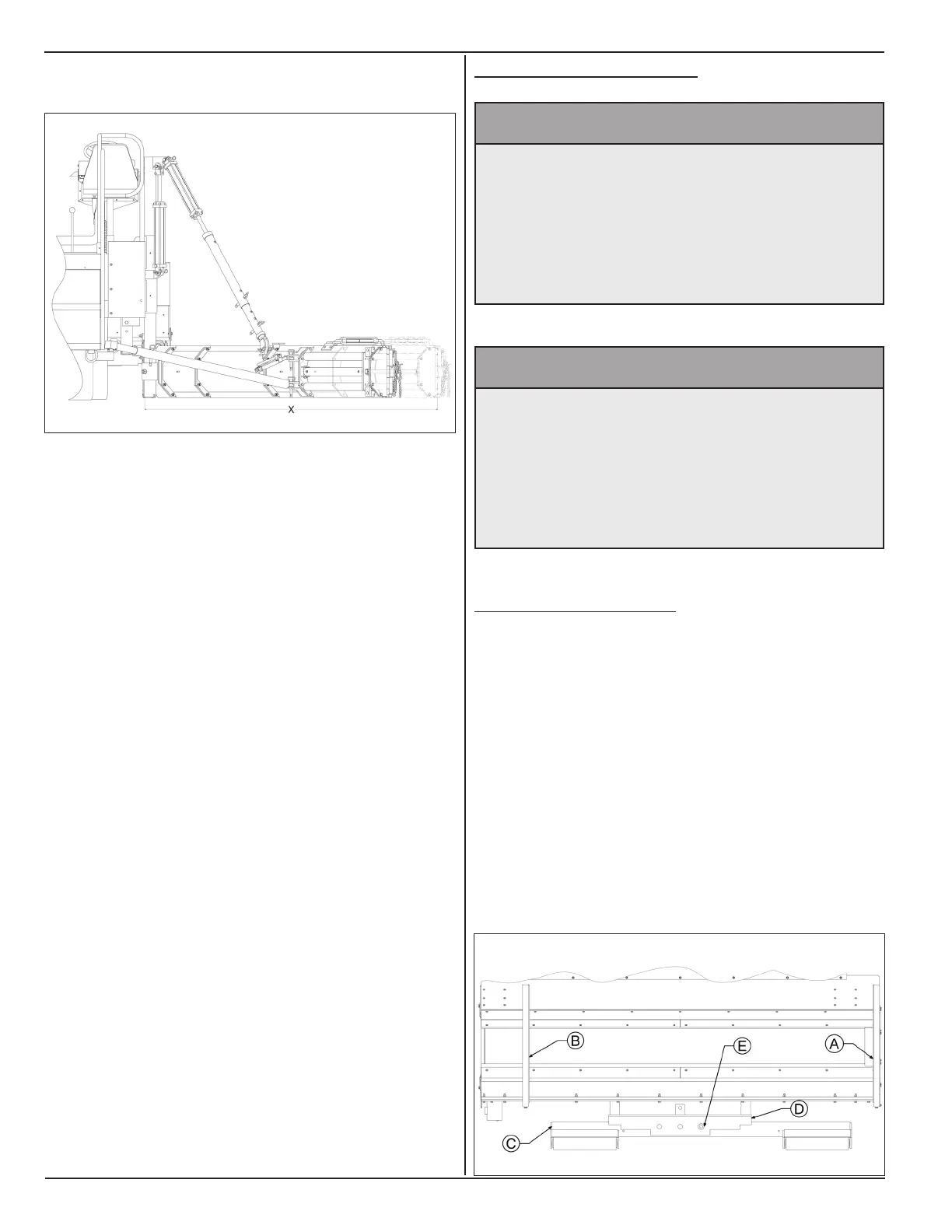

5.4.1 pIvot pIn loCAtIon

Pivot pin position for the push roller must be such that

push roller beam is symmetrically in middle between

end gates.

1. On a single sided machine, for right side paving,

location of left (A) and right (B) end gates are as

shown.

2. For this conguration, slide push roller beam (C)

towards left so pivot hole on push roller beam (C) is

in line with left hole on push roller mount (D).

3. Insert pivot pin (E) through in-line holes.

Loading...

Loading...