EXP-925

Midtronics B.V. Hoofdveste 6 - 8 Houten NL

www.midtronics.com

19

Chapter 5: System Test

Alternator Test

1. The tester starts checking for alternator output.

NOTE: If necessary the analyzer will ask if you are

testing a diesel engine. It will resume testing after

you make your selection.

2. Depending on whether you are working with an inte-

grated Amp clamp, you will be either prompted to TURN

OFF LOADS AND ENGINE or asked to CHECK IF CLAMP

POINTS AWAY FROM THE NEGATIVE BATTERY POST.

In case of the former, turn o vehicle loads (blowers,

interior light, radio, etc.) and the engine. Press the NEXT

soft key to continue.

3. ANALYZING CHARGING SYSTEM DATA

4. TURN OFF LOADS AND ENGINE: Turn o vehicle loads

(blowers, interior light, radio, etc.) and idle the engine.

Press the NEXT soft key to continue.

NOTE: If necessary the analyzer will ask if you are testing

a diesel engine. It will resume testing after you make

your selection.

5. REV ENGINE WITH LOADS OFF FOR 5 SECONDS: Rev the

engine with the loads o. Gradually increase the rpm un-

til the analyzer tells you to HOL

D the rev level as the bar

on the display crosses the rpm target line.

6. ACQUIRING DATA....HOLD ENGINE RPM: Continue to hold

the rpm while the Tester takes system measurements.

7. ENGINE REV DETECTED, IDLE ENGINE: The Tester has de-

tected the rev. Press the NEXT soft key to continue.

8. TESTING ALTERNATOR AT IDLE, LOADS OFF: The analyzer

will next test the engine at idle for comparison to other

readings, and then test the diode ripple. Excessive ripple

usually means one or more diodes have failed in the al-

ternator or there is stator damage.

9. TURN HIGH BEAMS AND BLOWER MOTOR ON, IDLE EN-

GINE: After a few seconds, the Tester will ask you to turn

on the accessory loads. It will determine if the charging

system is able to provide enough current for the de-

mands of the electrical system.

IMPORTANT: Turn on the high-beam headlights, the

blower to high and the rear defogger. Don’t use cyclical

loads such as air conditioning or windshield wipers.

10. TESTING ALTERNATOR AT IDLE, LOADS ON: The analyzer

will determine if the charging system is able to provide

sucient current for the demands of the vehicle’s elec-

trical system.

11. REV ENGINE WITH LOADS ON FOR 5 SECONDS: The Tes-

ter will test the charging system with the loads on and

prompt you to rev the engine. Gradually increase the rev

until the analyzer tells you to HOLD the rev level as the

bar on the display crosses the rpm target line.

12. ACQUIRING DATA....HOLD ENGINE RPM: Continue to hold

the rpm while the Tester takes system measurements.

13. ENGINE REV DETECTED, IDLE ENGINE: The Tester has de-

tected the rev. Press the NEXT soft key to continue.

14. ANALYZING CHARGING SYSTEM DATA: The Tester is com-

pleting its nal analysis of the charging system data.

15. TURN OFF LOADS AND ENGINE: Press the NEXT soft key

to display the results.

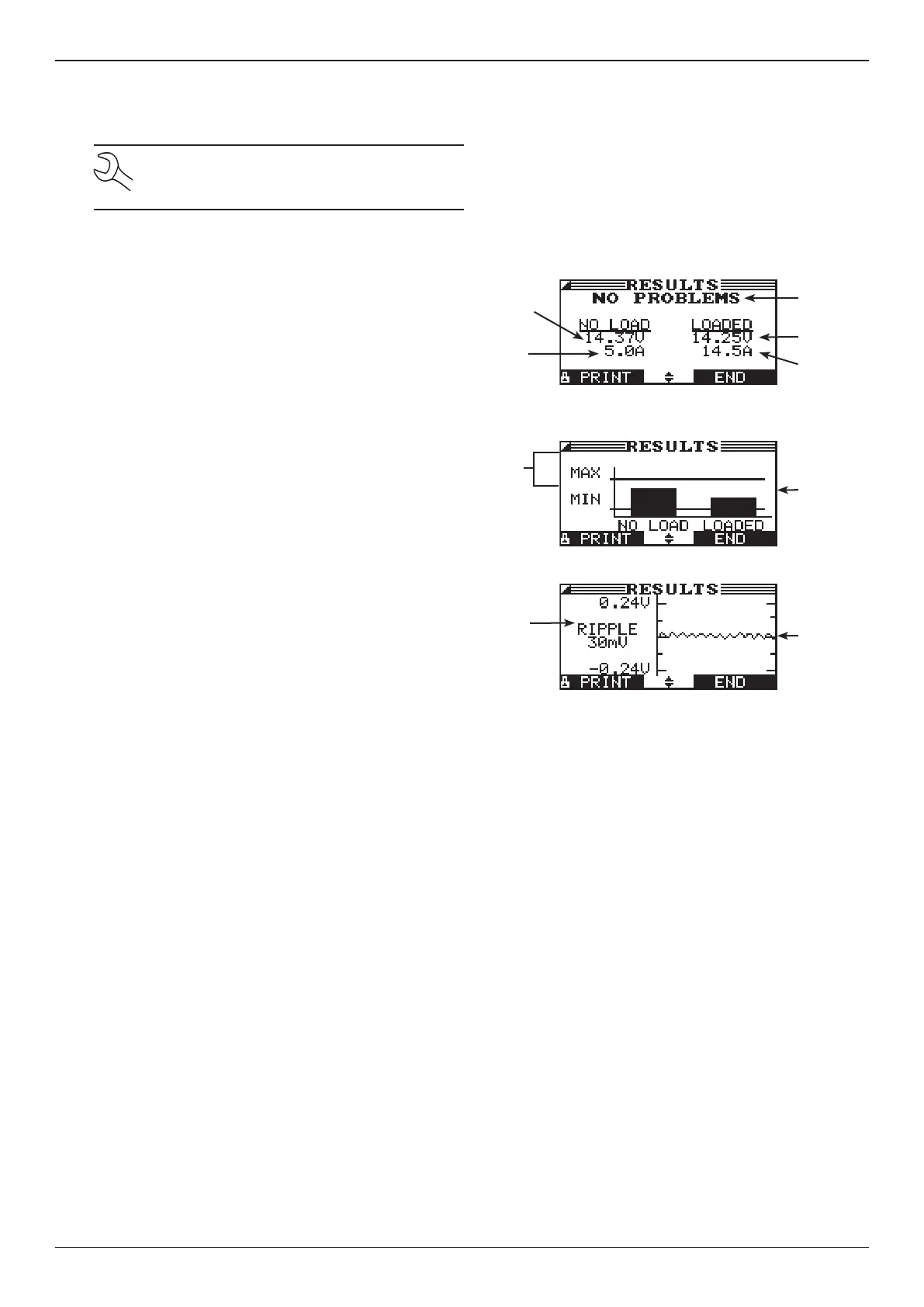

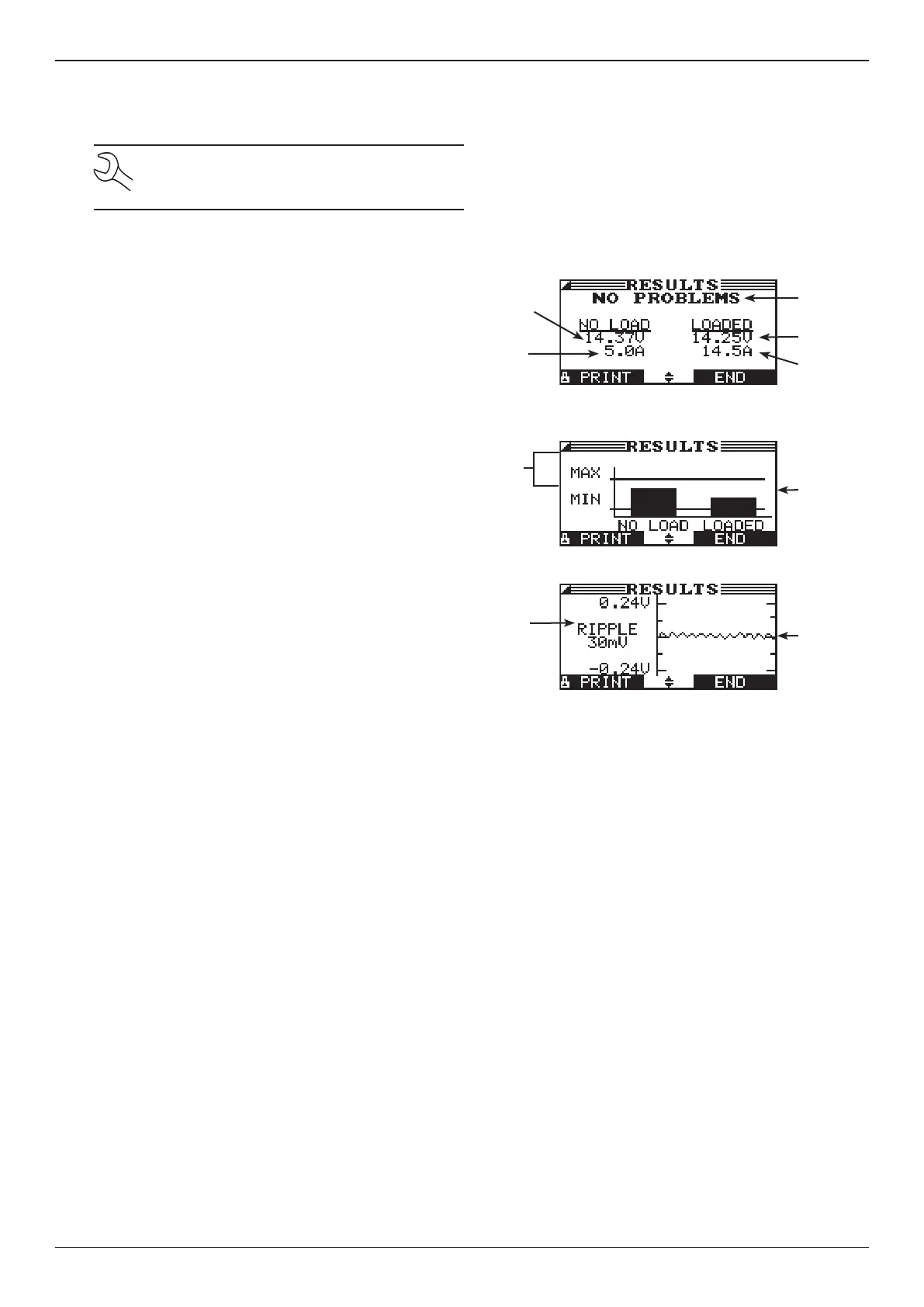

Alternator Test Results

NO PROBLEMS

Alternator Result

Alternator

decision

Loads-off

DC voltage

at rev

Loads-off

current at

rev if amp

clamp is

used

Loads-on DC

voltage at rev

Loads-on cur-

rent at rev if

amp clamp is

used

Normal

DC

voltage

range

Bar graph

showing DC

voltage within

normal range

with loads on

and off

Graph of

diode

waveform

Peak-to-

peak AC

voltage

Loading...

Loading...