14

GENERAL DESCRIPTION

DELTA 140E/160E is a monophased welding machine based on the Power Mosfets technology. It

has been constructed especially for those applications where welding jobs must be completed

quickly and easily. Using the latest inverter technology, MIGATRONIC has designed and produced

a compact welding machine able to weld with all types of electrodes (not high-yield electrodes) at

currents up to 140/160 amps.

The combination of low weight and compact design makes the DELTA 140E/160E extremely

suitable for installation work, field construction, emergency repairs, etc.

The electronics of the machine will keep the welding current stable at the set level by automatically

readjusting mains voltage and load variations.

DELTA 140E/160E is very easily operated since it is only fitted with one knob for infinitely variable

adjustment of the welding current from 10-140 A on DELTA 140E and 20-160 A on DELTA 160E.

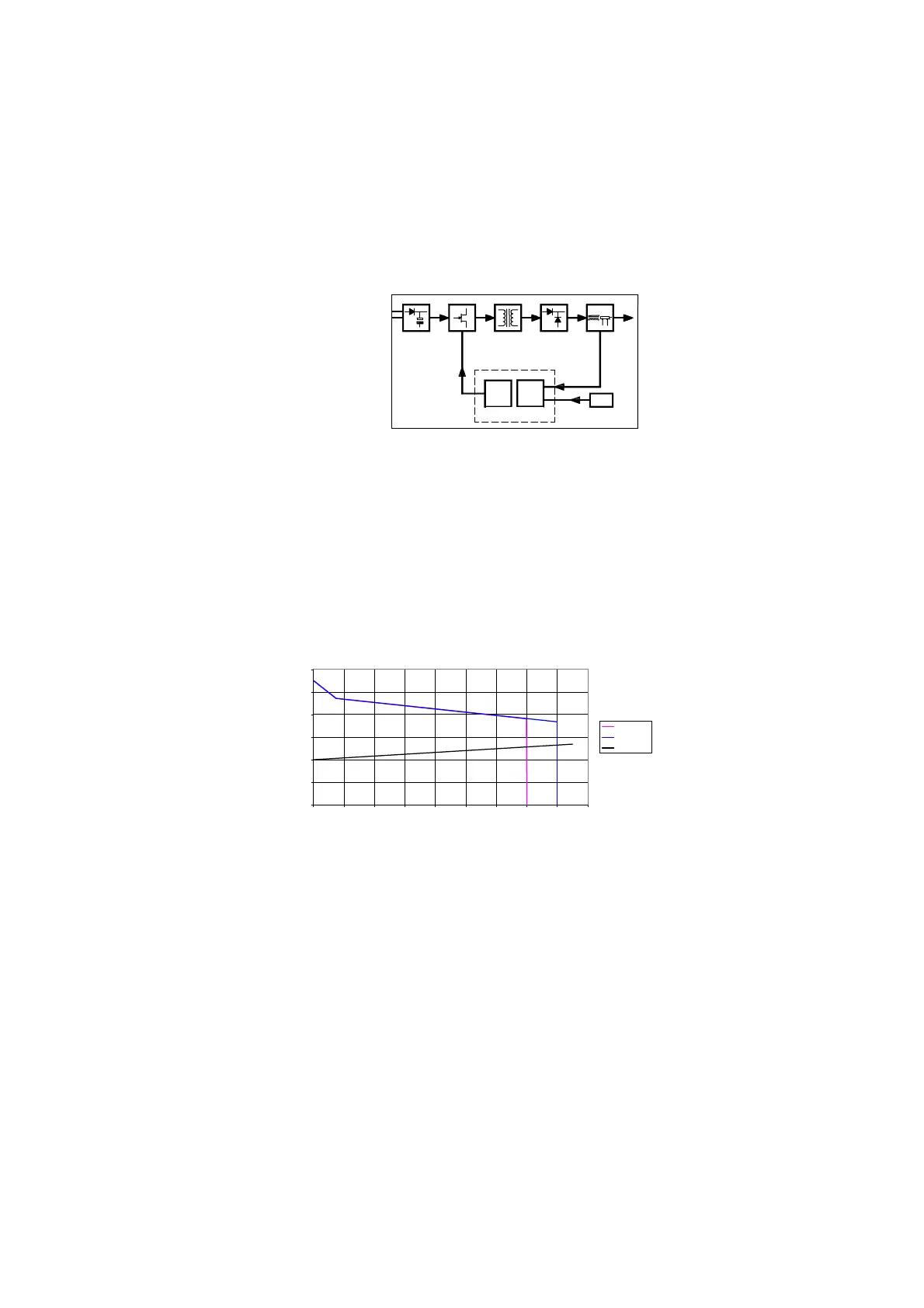

The block diagram illustrates

the principle of the machine.

The machine is equipped with the following fixed functions:

Hotstart:

This auxiliary function helps to establish the arc when MMA welding starts. This is done by

increasing the welding current (when the electrode touches the workpiece) compared to the set

welding current. This function facilitates the ignition of the electrode and results in quicker and

better welding.

Arc control:

When arc and weld pool have been established, this function will ensure that the arc is kept stable,

and that the result will be a more uniform welding.

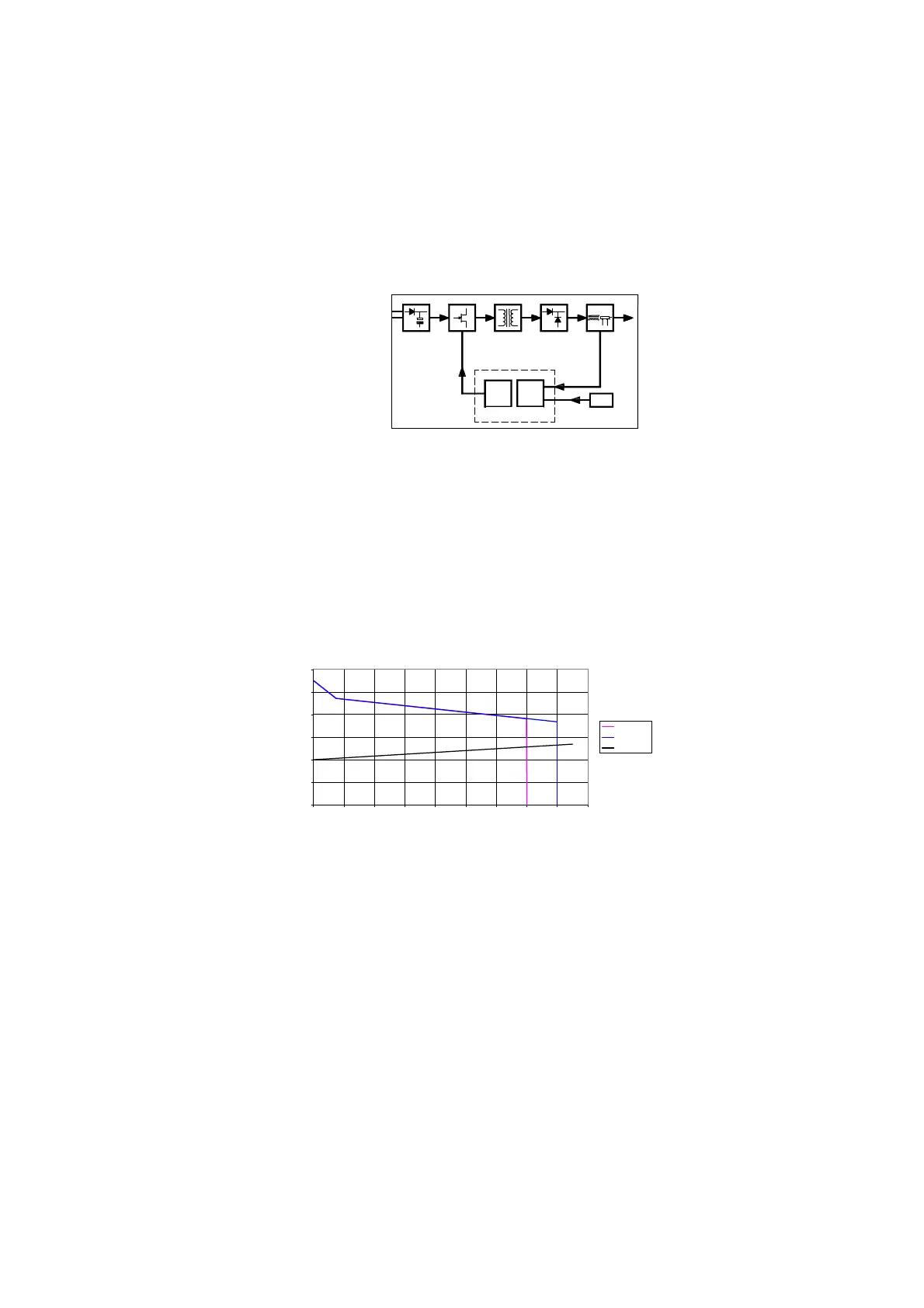

Static characteristic

Static Characteristic

0,0

10,0

20,0

30,0

40,0

50,0

60,0

0 20 40 60 80 100 120 140 160 180

I

2

[A]

U

2

[V]

Delta 140E

Delta 160E

Norm line

The static characteristic graph illustrates that the machine performs up to 140A/160A at 26V. The

high performance of the machine presupposes a mains voltage of not less than 230V.

REGU-

LATOR

Switch

driver

REF

CONTROL

Loading...

Loading...