. A complete Parts List is available at www.MillerWelds.com

OM-253086 Page 35

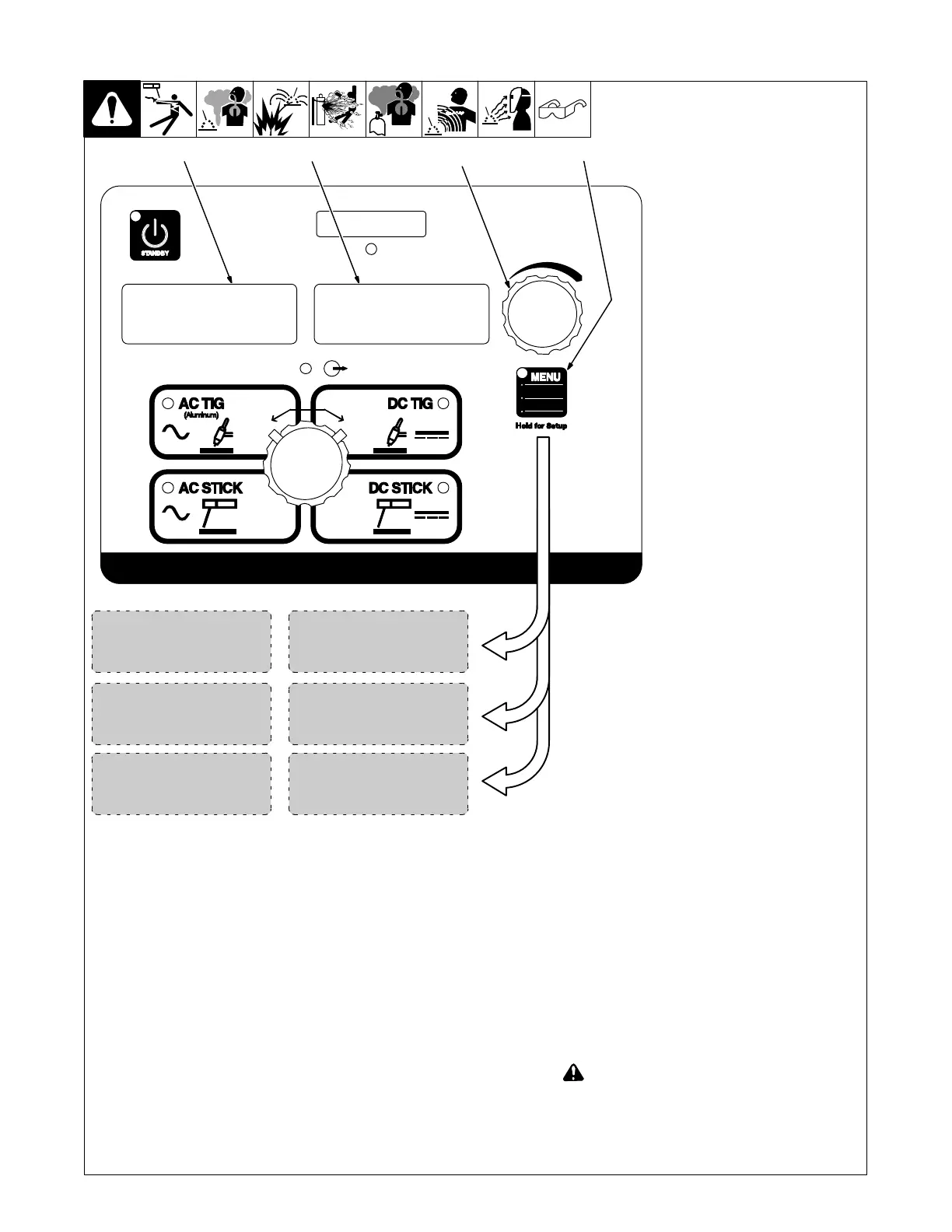

6-5. Accessing User Setup Menu: AC And DC TIG

1 Menu Button

Press and hold Menu button for ap-

proximately two seconds to access

machine configuration menus. Use

Menu button to cycle through para-

meters that can be set.

2 Parameter Display

3 Setting Display

4 Encoder

Rotate Encoder to adjust paramet-

er setting.

. To exit menu, press and hold

Menu button until Menu Off is

displayed.

1

STD

3/32TUNG

RMT

MENU

2

3

4

Tungsten Diameter Selection:

Each tungsten size has preset starting parameters

specific to that diameter for optimized starting.

Range is 0.020 in.−1/8 in. or 0.5 mm−3.2 mm.

Trigger Mode Selection:

[RMT] [STD]

Typically used with a remote foot or hand control.

RMT STD requires a maintained contact closure to

enable weld output. Amperage can be controlled

with a remote potentiometer, or it can be set at the

control panel.

[RMT] [HOLD]

Remote control required. Allows the operator to weld

without holding the trigger closed. To start the weld,

operator presses and releases trigger. To stop the

weld, the operator again presses and releases the

trigger. In this mode, only the output contactor is con-

trolled by the remote control. Amperage must be set

on the control panel.

[OUT] [ON]

Output on. (Lift Only)

! Weld output terminals are energized at all

times when displays read [OUT] [ON].

No remote control or trigger required. Amperage can

be controlled at the control panel or with a remote po-

tentiometer

. Blue output on LED illuminates to indic-

ate output is on.

Arc Starting Method Selection:

[STRT] [HF]

Is a non-contact starting method (see Section16-1).

[STRT] [LIFT]

Is a contact starting method (see Section16-1).

HF

USER

STRT

Or

247222-D