. A complete Parts List is available at www.MillerWelds.com

OM-253086 Page 43

HF START

Schedule 1

Schedule 2

LIFT ARC

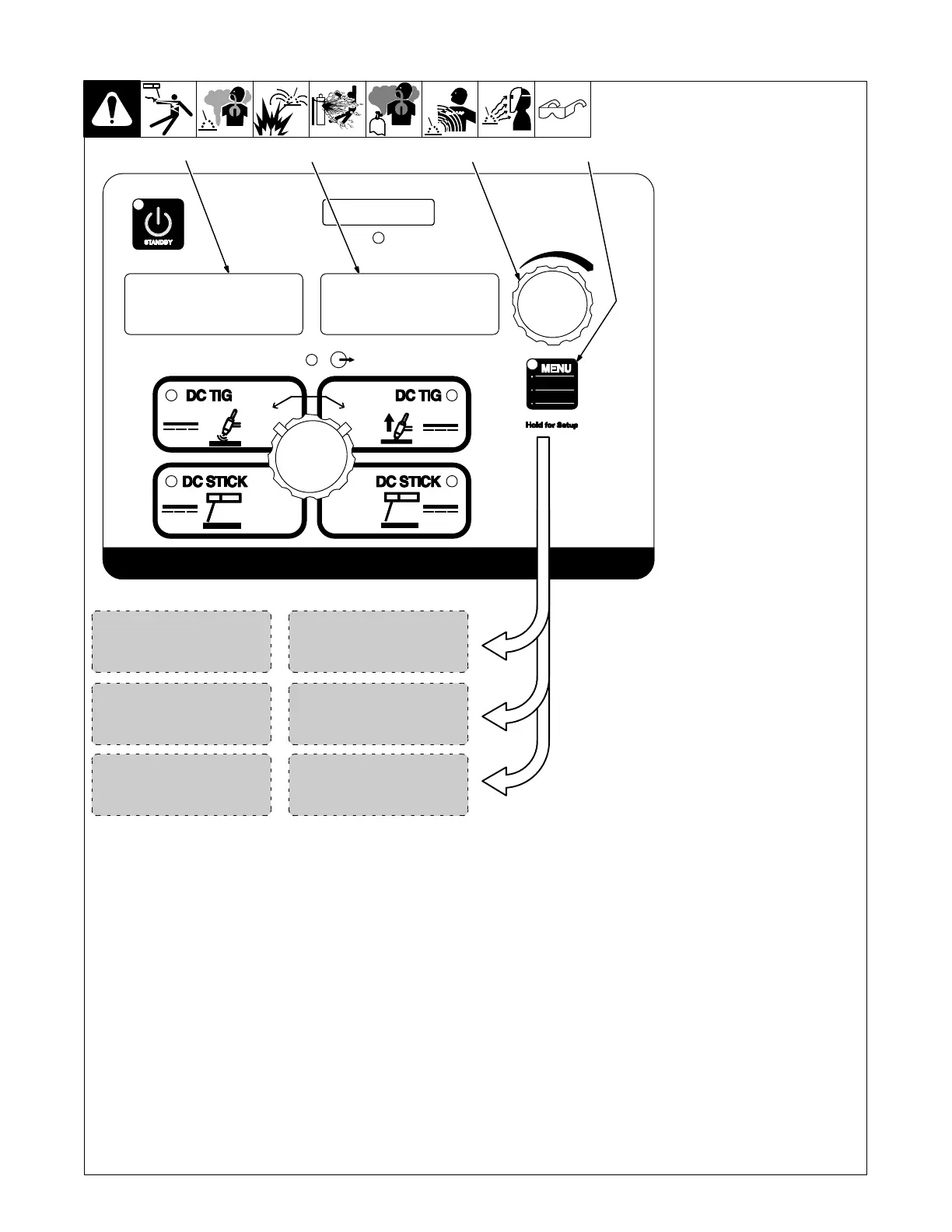

8-2. Accessing Control Panel Menu: DC TIG HF And Lift Arc

1 Menu Button

Press Menu button to cycle through

parameters that can be set.

2 Parameter Display

3 Setting Display

4 Encoder

Rotate Encoder to adjust paramet-

er setting.

. Parameter automatically re−

turns to amperage setting 15

seconds after Encoder is

inactive.

1

AUTO

OFF

PPS

POST

150A

2

3

4

Amperage Control:

Controls the welding amperage output. Limits the

maximum output of a remote amperage device.

150A

[PPS]* Pulse Control:

Reduces heat input to minimize distortion and increase

travel speed. Set PPS (pulses per second). The range

is OFF−250 PPS. The Background Amperage and Peak

Amperage are not adjustable. Background Amperage

equals 25% of Peak amperage. Peak amperage Time

equals 40%.

[POST] Post Flow Control:

Controls the length of time gas flows after welding

stops. Range is AUTO, OFF−50T (seconds). AUTO

calculates the time based on the maximum amperage

of each weld cycle. The minimum time is 8 seconds.

Auto equals maximum amperage/10.

*PRO−SET provides PROfessionally developed

SETtings for the weld process. To use PRO−SET,

press the menu button to display the parameter and

adjust the encoder until PRO−SET flashes on the dis-

play. PRO−SET flashes one time and reveals the pro-

fessional setting for the parameter.

Or

247218-C