. A complete Parts List is available at www.MillerWelds.com

OM-253086 Page 44

HF START

Schedule 1

Schedule 2

LIFT ARC

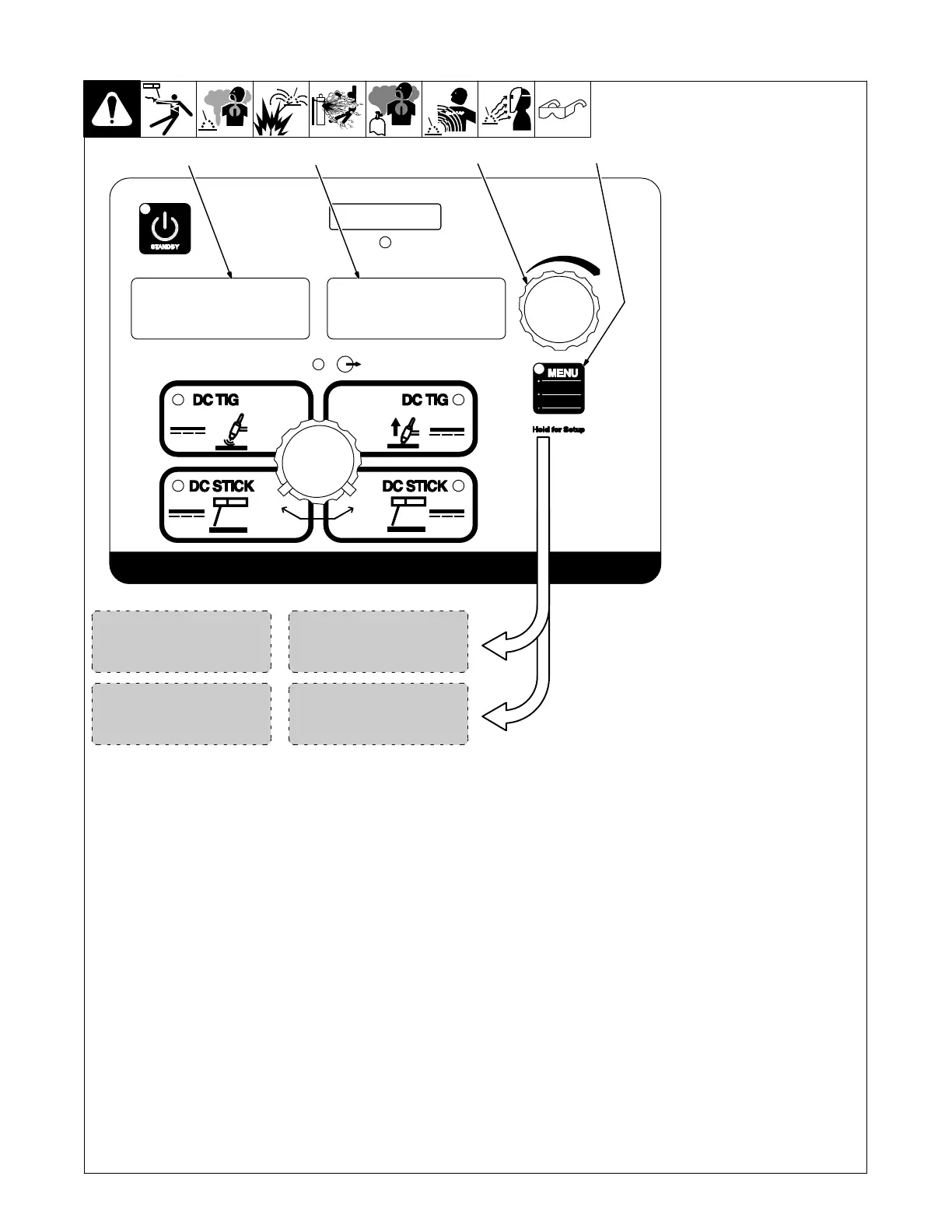

8-3. Accessing Control Panel Menu: DC Stick

1 Menu Button

Press Menu button to cycle

through parameters that can

be set.

2 Parameter Display

3 Setting Display

4 Encoder

Rotate Encoder to adjust para-

meter setting.

. Parameter automatically

returns to amperage set-

ting 15 seconds after En-

coder is inactive.

1

30%DIG

110A

2

3

4

[DIG]* Arc Force Control:

Controls the amount of additional amperage at low

voltage (short arc length) conditions. Adjust the

force of the arc for different joint configurations and

electrodes. Range is OFF−100%. Features

PRO-Set values for both 6010 and 7018 electrodes.

110A

Amperage Control:

Controls the welding amperage output. Limits the

maximum output of a remote amperage device.

*PRO−SET provides PROfessionally developed

SETtings for the weld process. To use PRO−SET,

press the menu button to display the parameter and

adjust the encoder until PRO−SET flashes on the

display. PRO−SET flashes one time and reveals the

professional setting for the parameter.

Or

247218-C

*CARB-ARC at one step above DIG’s 100% CARBon

ARC Gouging can be selected.