J

Joanne ParkAug 8, 2025

What to do if having issues with drive rolls on Miller Welding System?

- NNathan MosleyAug 8, 2025

To address issues with drive rolls on your Miller Welding System, you should clean and tighten them.

What to do if having issues with drive rolls on Miller Welding System?

To address issues with drive rolls on your Miller Welding System, you should clean and tighten them.

What to do if gas hose is damaged on Miller XR-30A?

If the gas hose on your Miller Welding System is damaged, replace it.

What to do if labels are damaged on Miller XR-30A?

If the labels on your Miller Welding System are damaged or unreadable, replace them.

Details potential hazards associated with arc welding processes, including shock, fumes, and fire.

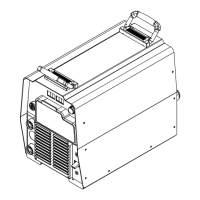

Outlines how to connect the welding equipment to various types of power sources.

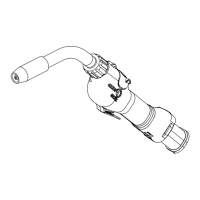

Explains the functions of the trigger and wire speed control on the welding gun.

Provides a step-by-step guide for replacing the welding gun liner.

Instructions on how to change the welding gun's contact tip.

Procedures for replacing or cleaning drive rolls and their bearings.

Provides solutions for common problems encountered with the welding gun.

| Input Frequency | 50 / 60 Hz |

|---|---|

| Rated Output | 300A at 32V, 60% duty cycle |

| Duty Cycle | 60% |

| Wire Diameter | 0.8–1.2 mm |

| Processes | Pulsed MIG |

Loading...

Loading...