PELLERIN MILNOR CORPORATION

• Install safety stands before performing maintenance under a tilted machine.

• NEVER test or operate (manually or automatically) any machine function with any

portion of a person's body under the tilted machine - even if the safety stands are installed.

WARNING 6 : Crush/Sever hazard—Tilt machines with tilt wheels/cradles may lunge

forward or rearward and even fall over if the non-tilted ends are raised out of their cradles -

killing/injuring personnel and/or damaging property.

• NEVER manually tilt (lift) both ends of the machine at the same time. One end must

always be seated in its cradle.

• ALWAYS visually inspect the tilt wheels to be sure they are all fully seated in their

cradles before each manual tilt up.

• Pneumatic valve manual operation must be done by trained competent maintenance

personnel who thoroughly understand the system and all the consequences of manual

operations.

• ALWAYS understand beforehand all the consequences of manually operating pneumatic

valves.

• NEVER permit operation with malfunctioning tilt limit switches

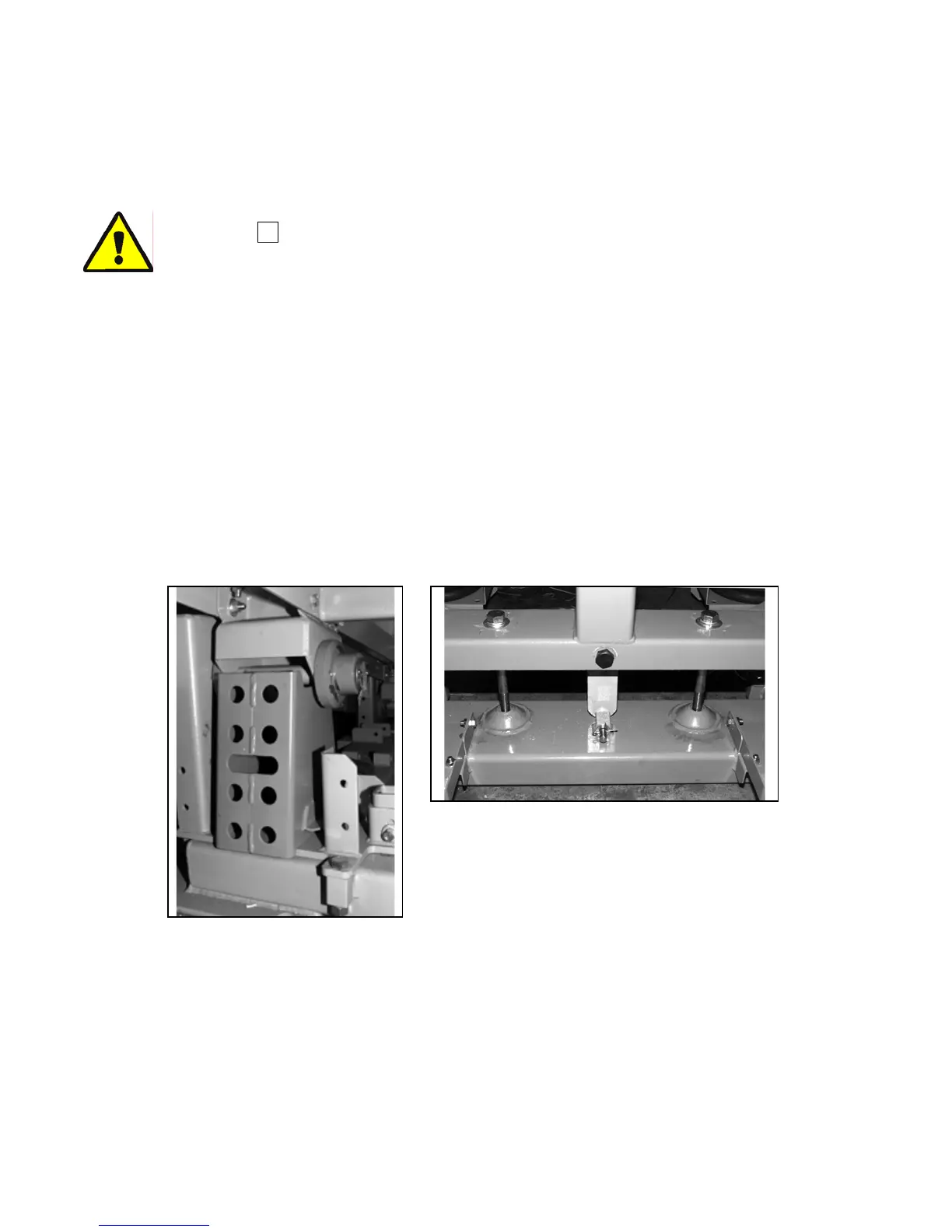

Tilting machines leave the factory with 4 hold-down bolts (two per side) locking the tilting mid-

frame to the floor frame (Figure 7). Remove these bolts after machine is anchored and grouted,

service connections are complete and all other installation steps are complete.

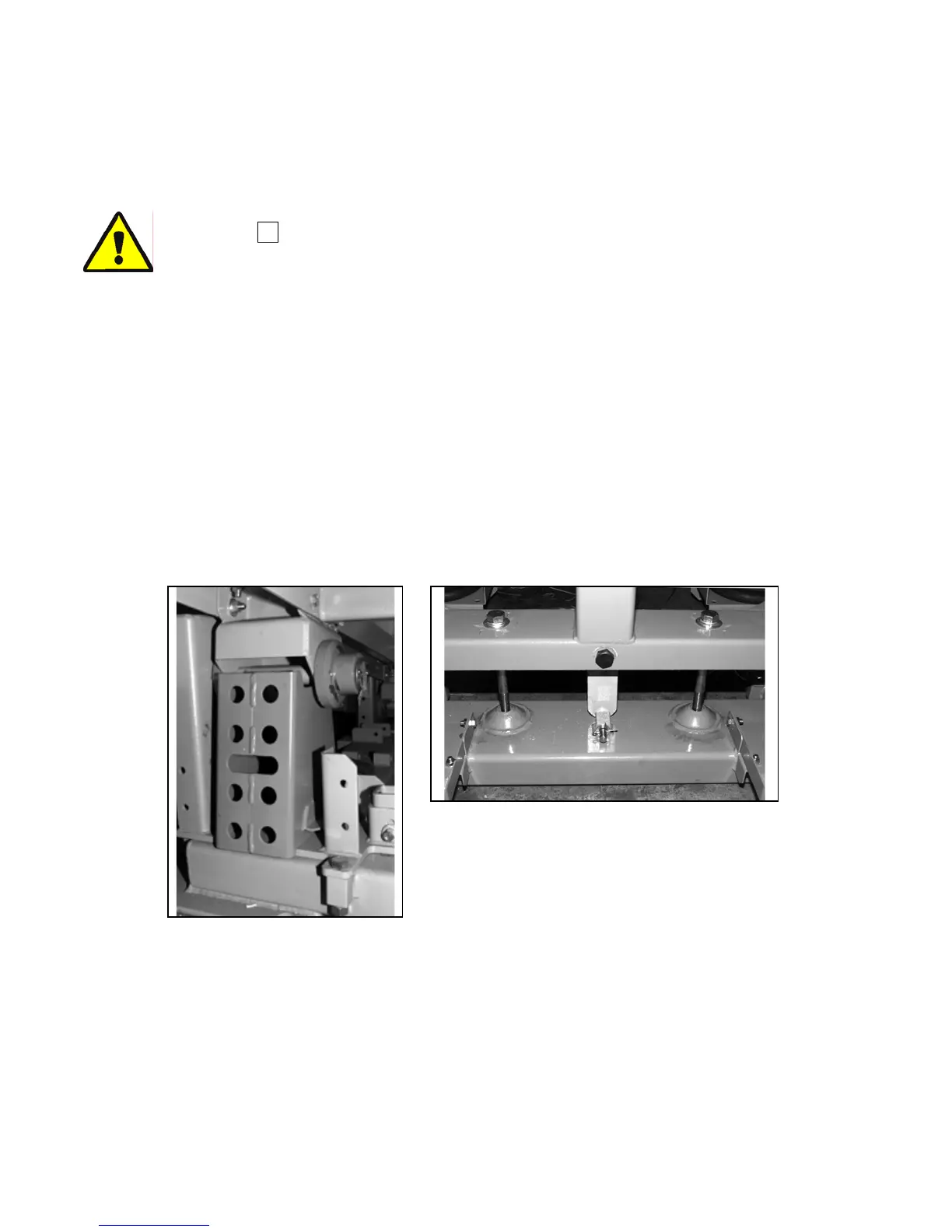

Figure 6: Safety stand in place Figure 7: Tilting Mid Frame to Floor Locking Bolts

— End of BIIFLI01 —

30

Loading...

Loading...