1 FUNCTIONS AND CONFIGURATION

Overview 1-1

1. FUNCTIONS AND CONFIGURATION

1.1 Overview

The safety communication function sends/receives safety I/O signals to/from the safety programmable controller.

The function is implemented with the safety monitoring function of the CR800-R/CR860-R controllers. The

following table lists safety monitoring functions that can be implemented with the safety communication function.

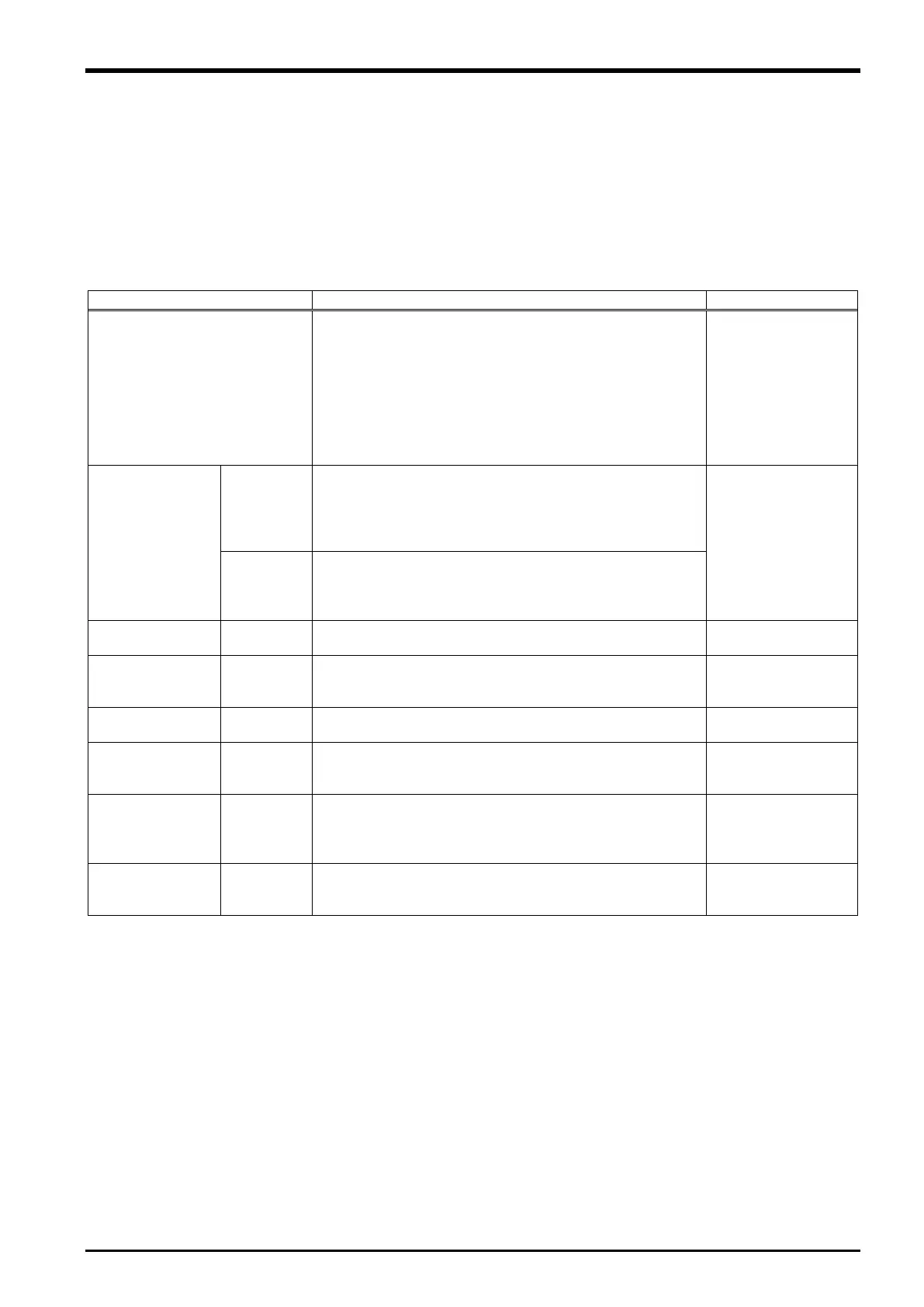

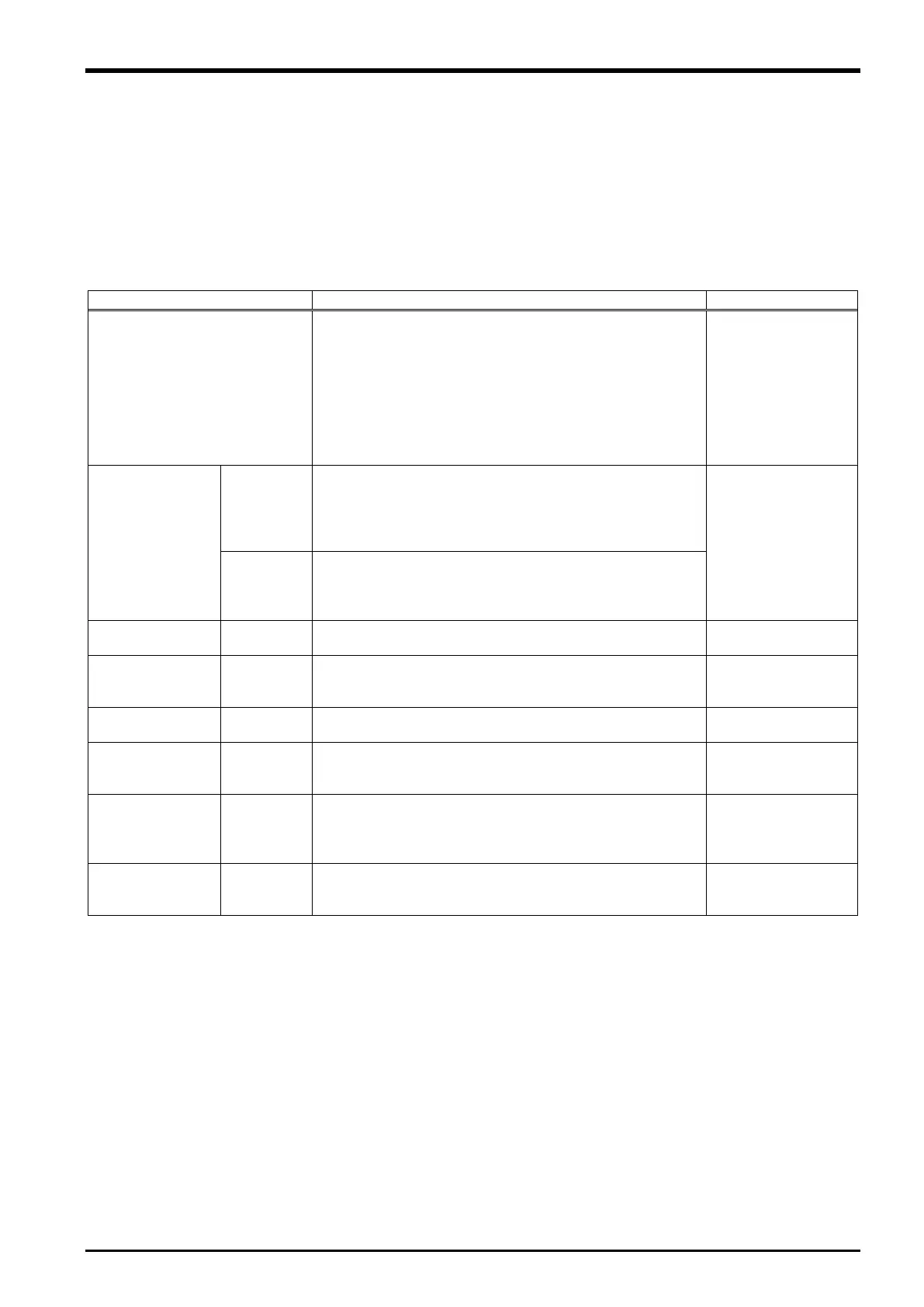

Table 1-1: Safety monitoring functions overview

function

This function performs safety communication with the

safety programmable controller using functional safety-

compatible protocols. Input signals are used to switch

the safety monitoring function, and output signals are

used to output the status of the safety monitoring

functions (safety logic edit).

When the safety communication function is enabled,

the following safety monitoring functions are available.

SS1 (STO), SS2 (SOS), SLS, SLP

Communication

Function

This allows defining conditions for the safety monitoring

function to work.

Safety input signals and the AREA information of the

robot can be combined to configure the conditions to

trigger the safety monitoring functions.

Edit

This allows outputting safety signals based on running

states of the safety monitoring functions and AREA

monitoring information. This is used for displaying

safety states or connecting other safety devices.

The function shuts off driving energy to the motors of

the robot.

4.5.1 Safe torque

off (STO)

stop

Without shutting off the driving energy to the motors,

this function monitors the robot so that it stays at rest.

operating stop

This is a function to stop the robot safely. After stopping

the robot, power off the motors.

function 2

This is a function to stop the robot safely. While the

motor control keeps working after the robot stops, this

function monitors the robot so that it does not work.

(SS2)

speed function

This is a function to monitor the robot arm and the tools

so that their speeds do not exceed specified limits.

• Speed monitoring in XYZ coordinates

• Speed monitoring in joint coordinates

speed function

(SLS)

position function

This is a function to monitor whether positions of the

robot arm and the hand are in a safe area.

position function

* To use safety I/O from external sensors such as laser scanners and light curtains with the robot controller, the

robot safety option (4F-SF002-01, 4F-SF003-05) is required when a safety programmable controller is not used.

The safety communication function and robot safety option cannot be used together.

Loading...

Loading...