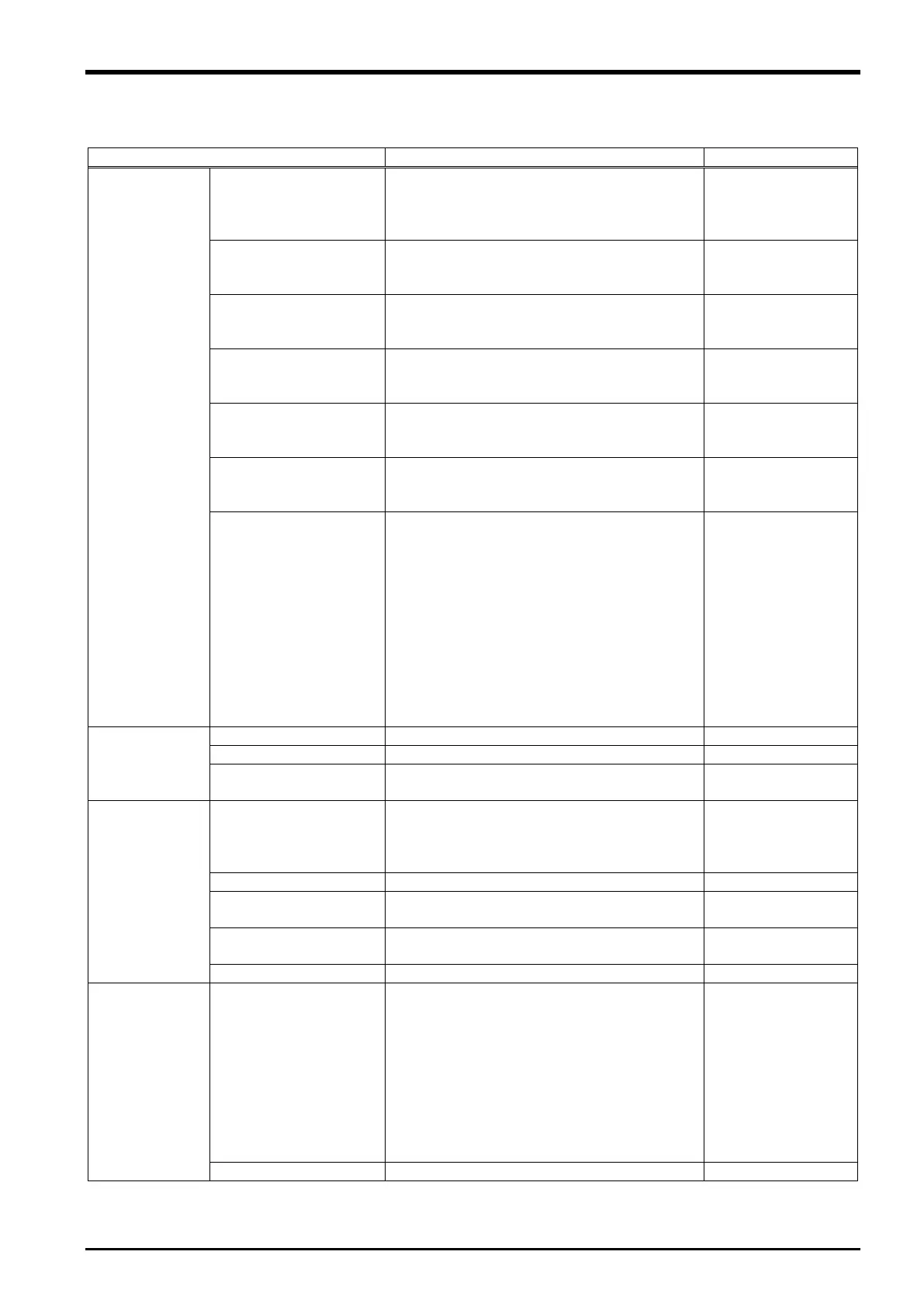

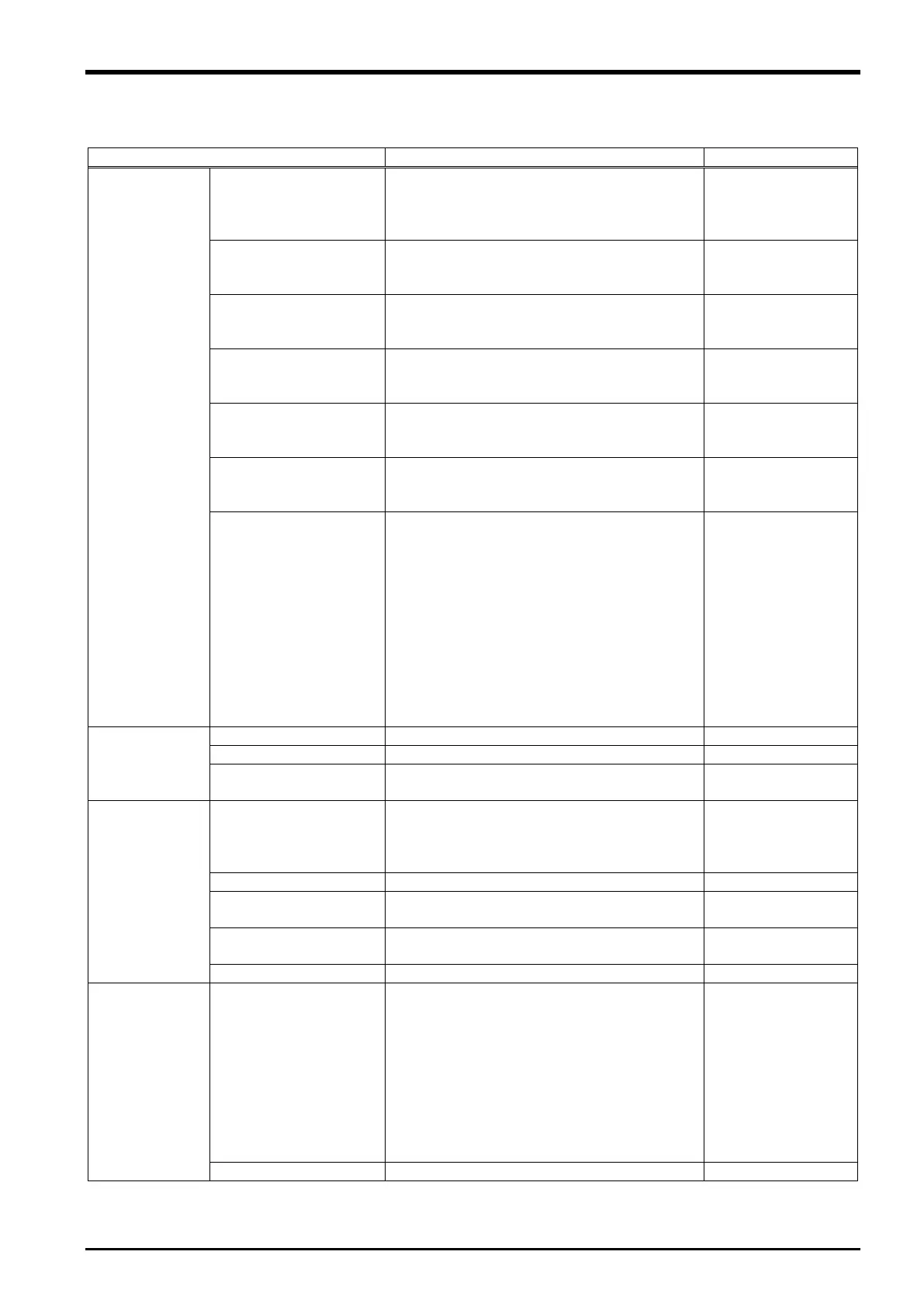

1 FUNCTIONS AND CONFIGURATION

1-6 Specifications

1.4 Specifications

Table 1-4 Specifications

The function electrically shuts off the driving

energy to the motor of the robot arm.

The driving energy to the motor is shut off,

which means that safety is ensured.

Corresponds to

stop category 0

The function to control and decelerate the

motor speeds of the robot. After stopping,

the robot transitions to the STO state.

Corresponds to

The function to control and decelerate the

motor speeds of the robot. After stopping,

the robot transitions to the SOS state.

Corresponds to

Without shutting off the driving energy to

the motors, this function monitors the robot

so that it stays at rest.

compliant

This is a function to monitor each part of the

robot arm so that their speeds do not

exceed monitoring speeds.

compliant

The function monitors specified monitoring

positions so that they do not go across

position monitoring planes.

compliant

function

This function performs safety

communication with the safety

programmable controller using functional

safety-compatible protocols. Input signals

are used to switch the safety monitoring

function, and output signals are used to

output the status of the safety monitoring

functions.

When the safety communication function is

enabled, the following safety monitoring

functions are available.

SS1 (STO), SS2 (SOS), SLS, SLP

compliant

communication

function

CC-Link IE TSN (CR800-R/CR860-R

controllers)

TSN

Local station (safety station)

Safety communication possible with the

MELSEC iQ-R series safety CPU module

CC-Link IE Safety Protocol Ver.2

Passive (safety connection established

from the communication destination)

Maximum number of

safety connections

7.11 ms (safety cycle time)

performance

EN ISO 13849-1:2015

IEC 61508-1:2010

IEC 61508-2:2010

IEC 61508-3:2010

EN 61800-5-1:2007/A1:2017

EN 61800-5-2:2017

IEC 61326-3-1:2017

EN 60204-1:2018

Loading...

Loading...