8 SYSTEM APPLICATION EXAMPLES

8-130 Application Example 2

8.2.6 Basic configuration (robot controller)

Configure the basic settings of robot controller safety functions.

Table 8-12 Basic settings

Enable / Disable the Safety Function

Safety Input / Output I/F

Communication partner IP address

<4> Local station (station No.3)

<5> Local station (station No.4)

<4> Local station (station No.3)

<5> Local station (station No.4)

Transmission interval monitoring time

8.2.7 Defining 3D models (robot controller)

Define arm and tool monitoring models.

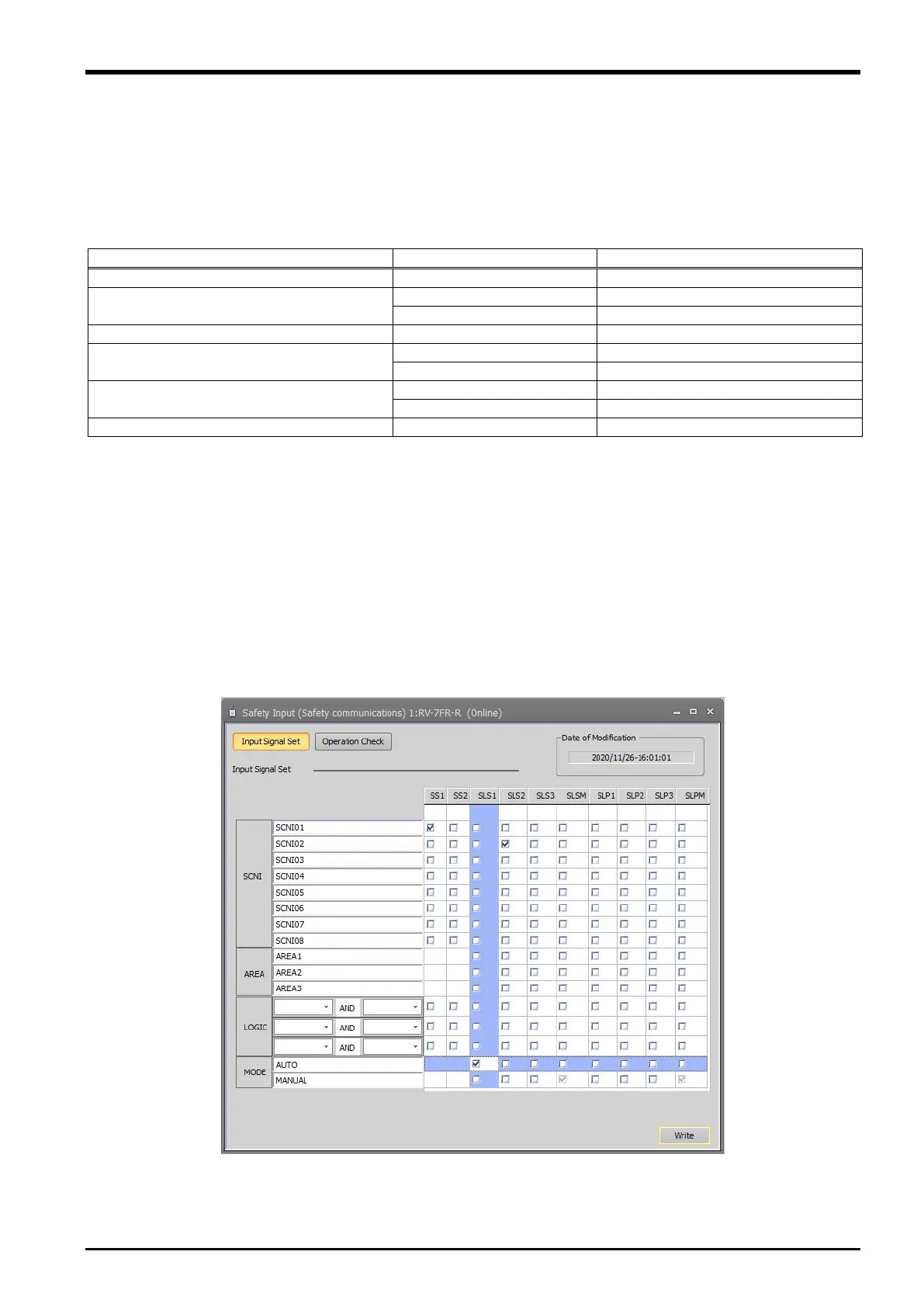

8.2.8 Safety logic edit (robot controller)

Set the safety logic of the robot controller.

・ When safety input SCNI01 is OFF, the SS1 function is activated.

・ When safety input SCNI02 is OFF, the SLS2 function is activated.

・ When MODE input is AUTO, the SLS1 function is activated.

Fig. 8-10: Safety logic setting example (safety input)

Loading...

Loading...