12-46 Simple inspection and service

An excessively loose or tight belt could cause the

engine to overheat, the battery to be inadequately

charged, or the alternator or water pump to mal-

function. Always keep belts adjusted to the proper

tension.

CAUTION

Prevent the V-belt from any contact with oil or

grease during check and adjustment.

If soiled with oil or grease, the belts will slip and

this will shorten their service life.

1Check

1. Confirm that the parking brake lever is pulled.

Prevent the vehicle from moving by blocking the

wheels with chocks. Tilt the cab. P. 12-5

If the vehicle is a crew-cab model, uncover the

engine inspection opening under the assistant

driver’s seat. P. 12-4

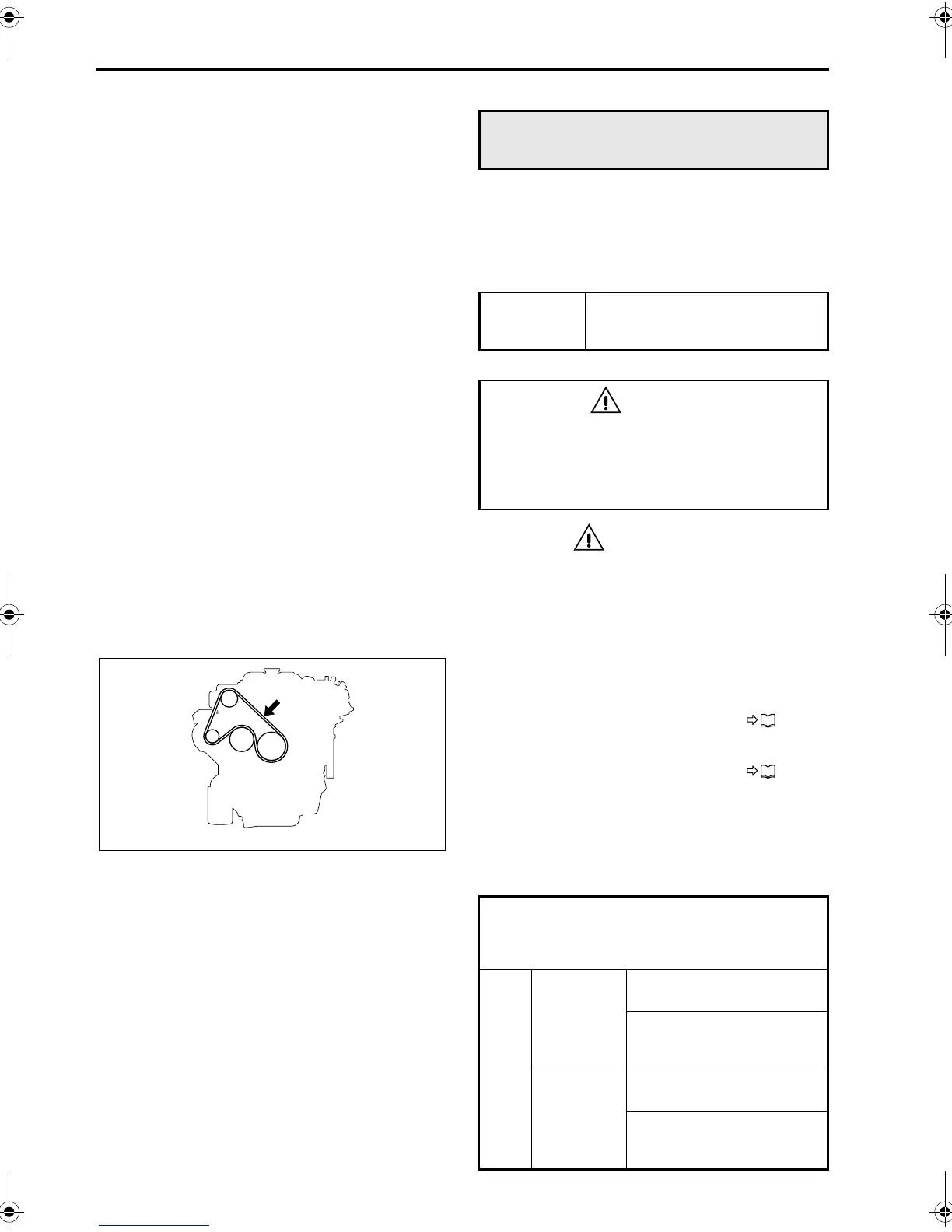

2. Press the belt with an approximately 98 N (22

lbs., 10 kgf) force at the point midway between

the pulleys, and measure the amount of deflec-

tion.

3. If the deflection is not as specified below, the

tension of the belt must be adjusted.

V-belts – check and adjustment

V-belt

inspection

intervals

At the time of pre-operational

check and every 10,000 km

(6,000 miles) or every 12 months

WARNING

Always stop the engine before inspecting or

adjusting belts.

Ensure that the engine cannot be started

while you are performing checks or adjust-

ments.

Belt tension

[Amount of deflection when the belt is pressed

with a 98 N (22 lbs., 10 kgf) force at the point

midway between the pulleys]

Fan

belt

Vehicles

without air

conditioner

New belt (when installed):

9 to 11 mm (0.35 to 0.43 in.)

Used belt (when inspected

or reinstalled): 11 to 13 mm

(0.43 to 0.51 in.)

Vehicles

with air

conditioner

New belt (when installed):

7 to 9 mm (0.28 to 0.35 in.)

Used belt (when inspected

or reinstalled): 10 to 11 mm

(0.39 to 0.43 in.)

Z11933

FEFG.book Page 46 Thursday, March 10, 2005 7:30 PM

Loading...

Loading...