How To Adjust the Valve Preload (MFC only) Cha

ter Seven: Troubleshootin

52

5. Set the gas supply regulator to the maximum expected operating pressure of your

processing system.

Warning

Follow your corporate policy on handling toxic or hazardous

gases. Your corporate policy on handling these gases

supersedes

the instructions in this manual. MKS assumes no

liability for the safe handling of such materials.

If appropriate, remove the MFC from the process tool and

make the adjustments using a surrogate gas.

6. Close all isolation valves in the system, both upstream and downstream of the MFC.

7. Zero the unit, following the instructions in

How To Zero the Flow Controller,

page 40.

8. Disconnect one electrical valve lead from its post on the PC Control board and connect a

DMM in series. Set the DMM to measure current in the 10 to 100 mA range.

9. Open all upstream and downstream isolation valves in the system.

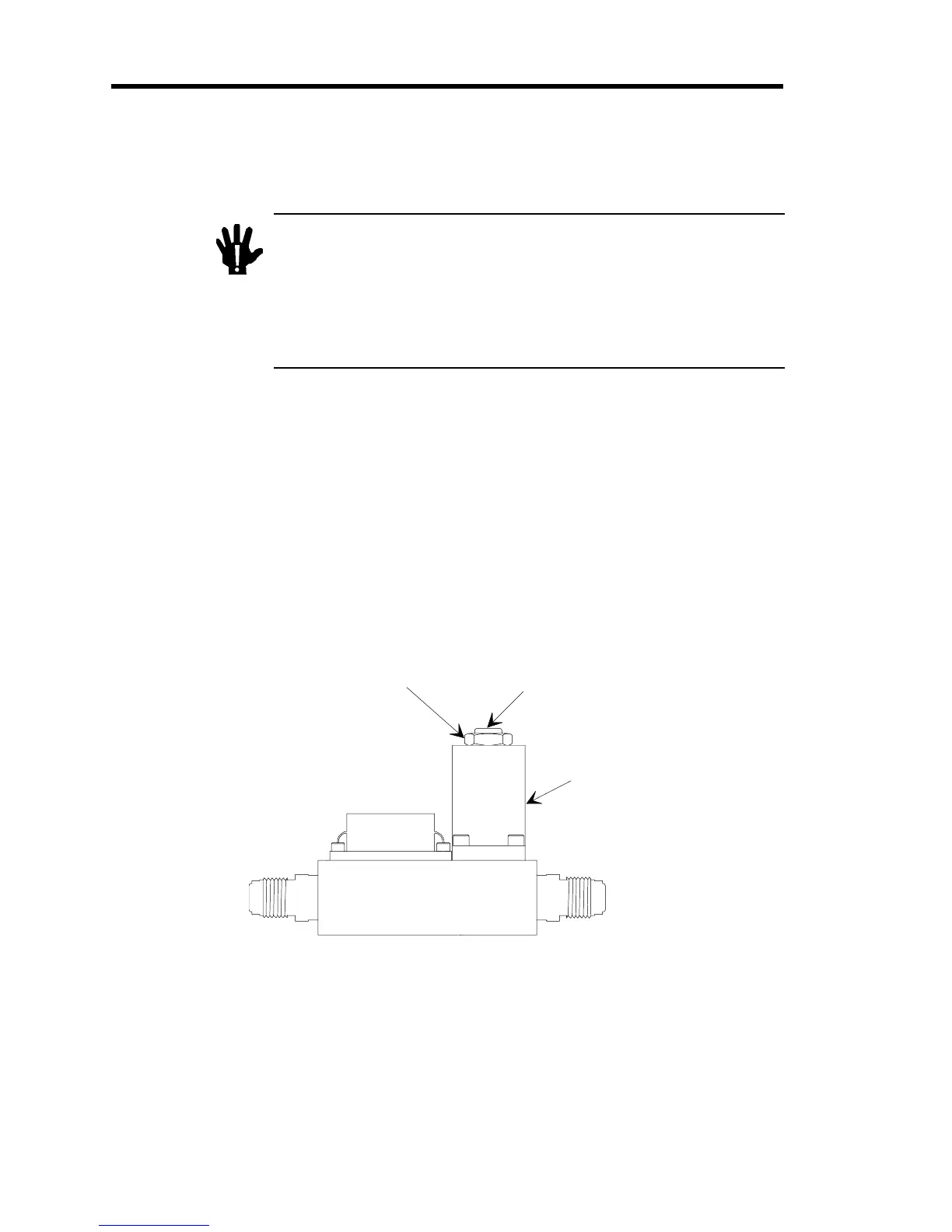

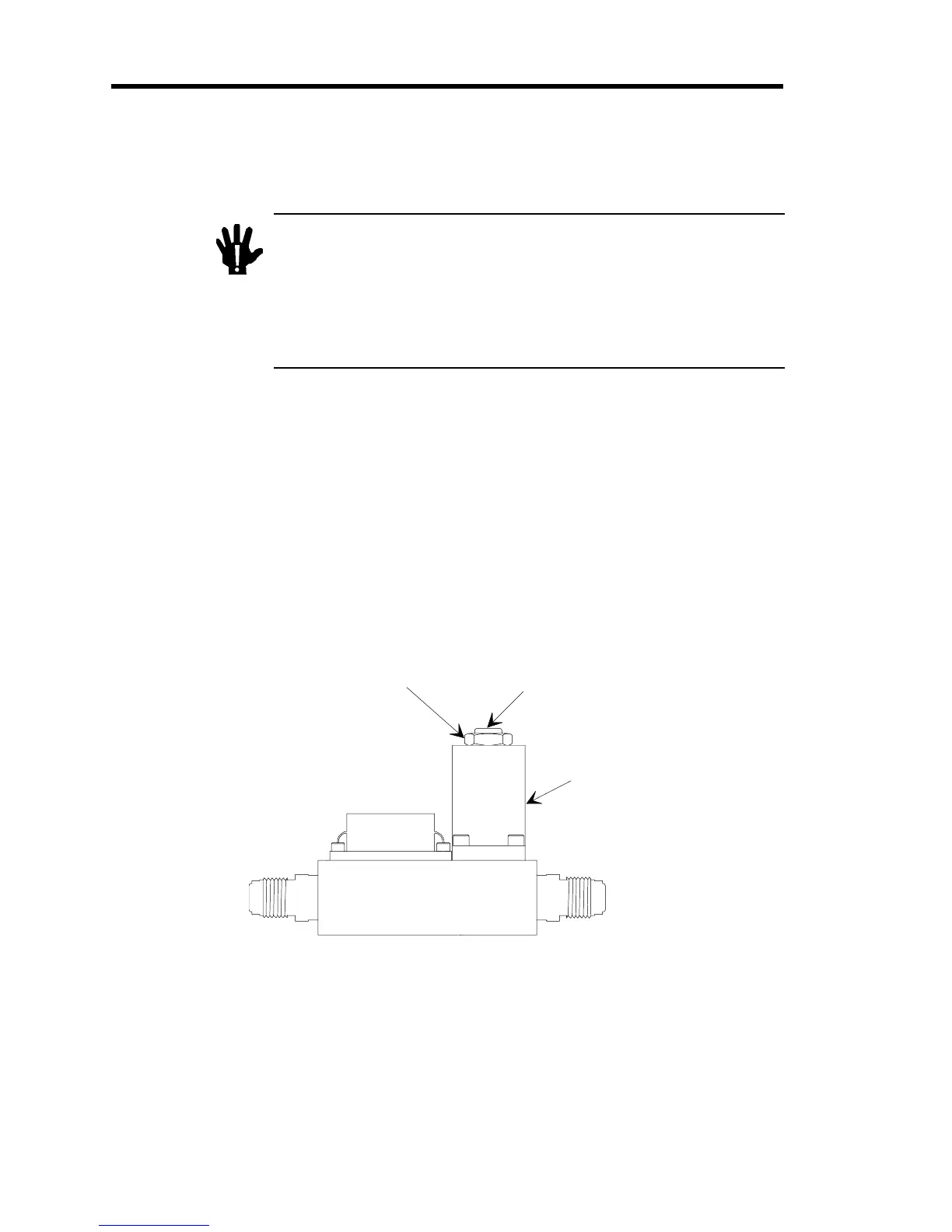

10. Hold the centershaft in place with a

3

/

16

” allen wrench and loosen the jam nut using a

9

/

16

”

crescent wrench.

Refer to Figure 9 for the location of the lock nut and centershaft.

Jam Nut

Centershaft

Valve Coil

Enclosure

Figure 9: Location of the Lock Nut and Centershaft

11. Provide a set point input signal to the MFC of 0.25 Volts to represent 5% flow.

Loading...

Loading...