Maintenance

Mini-Convectron Module Instruction Manual - 275513 49

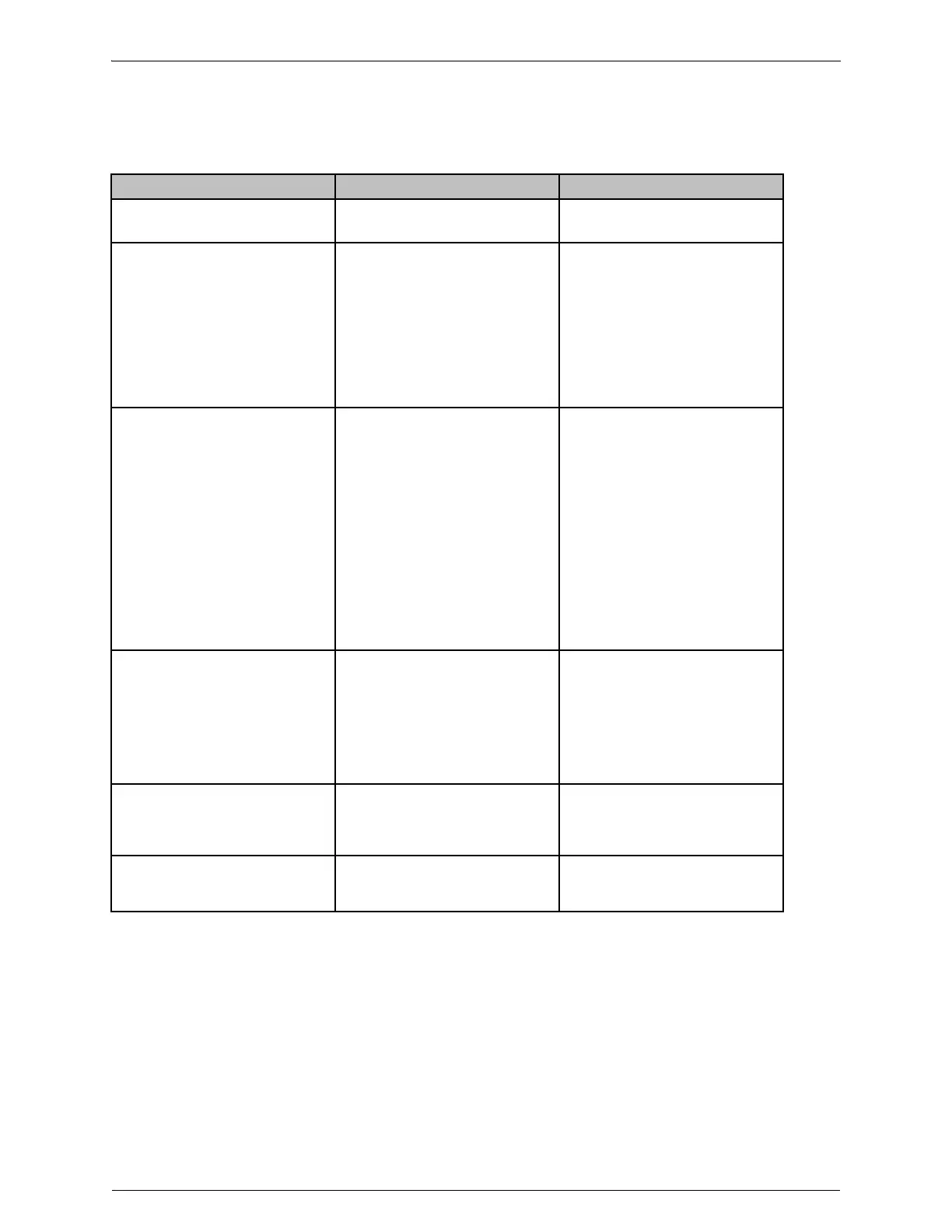

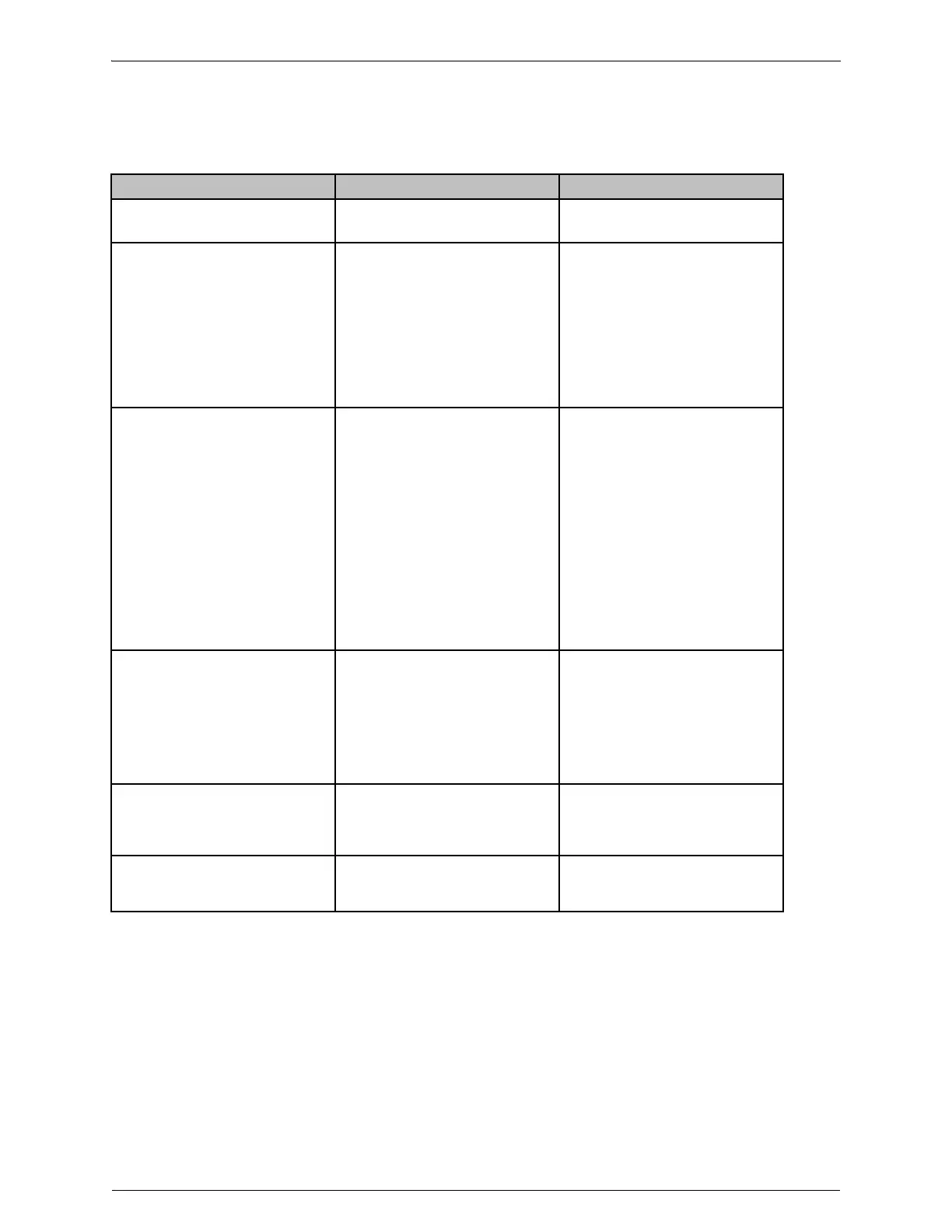

4.2.2 Symptoms, Causes, and Solutions

Table 4-1 lists failure symptoms, causes, and solutions.

Table 4-1 Failure Symptoms, Causes, and Solutions

Symptom Possible Causes Solution

Output voltage = 0 V 11.5 to 26.5 V power supply cable

is improperly connected or faulty.

Repair or replace power supply

cable (see Section 2.3.3).

Pressure reading is too high.

• Conductance in connection to

vacuum chamber is inadequate.

• Plumbing to module leaks or is

contaminated.

• Chamber pressure is too high due to

leak, contamination, or pump

failure.

• Power supply or output cable is

improperly connected or faulty.

• If conductance is inadequate,

reconnect Convectron gauge port to

vacuum chamber (see page 18).

• If plumbing leaks or is

contaminated, clean, repair or

replace plumbing.

• If pump failed, repair or replace it.

• If cable is improperly connected or

faulty, repair or replace cable (see

Section 2.3.3).

Pressure reading is inaccurate.

• Module is not calibrated for the

process gas that is being used.

• Module is not mounted horizontally.

• Convectron gauge or differential

pressure sensor is damaged (for

example, by reactive gas) or

contaminated.

• Temperature or mechanical

vibration is extreme.

• If Convectron gauge is out of

calibration, recalibrate it (see

Section 3.6).

• If module is not mounted

horizontally, re-mount it (see

Figure 2-4).

• If Convectron gauge is damaged,

replace it (see Section 4.4).

• If Convectron gauge is

contaminated, return it to factory

(see pages Section 4.1 and 51).

• If temperature or vibration is

extreme, relocate module or

eliminate source of heat or

vibration.

Indicated pressure is different than

pressure indications from other

measurement devices.

• Process gas is a not the gas that the

user anticipated using in the system.

• Convectron gauge is defective.

• If the process gas is not what was

anticipated, calibrate the

Convectron gauge for the gas being

used (see Section 3.2.1 and Section

3.2.2).

• If Convectron gauge is defective,

return it to factory (see pages 47

and 51).

Relay LED indicator is ON, but

relay is not functioning.

• Relay contacts are defective. • Make sure the relay load is within

the specified rating and is

non-inductive (see the

Specifications Appendix).

• Relay will not activate.

• Output voltage is < 0.10 V.

• A circuit board is faulty.

• Convectron gauge sensing wire is

open.

• Return module to factory (see

Section 4.1).

Loading...

Loading...