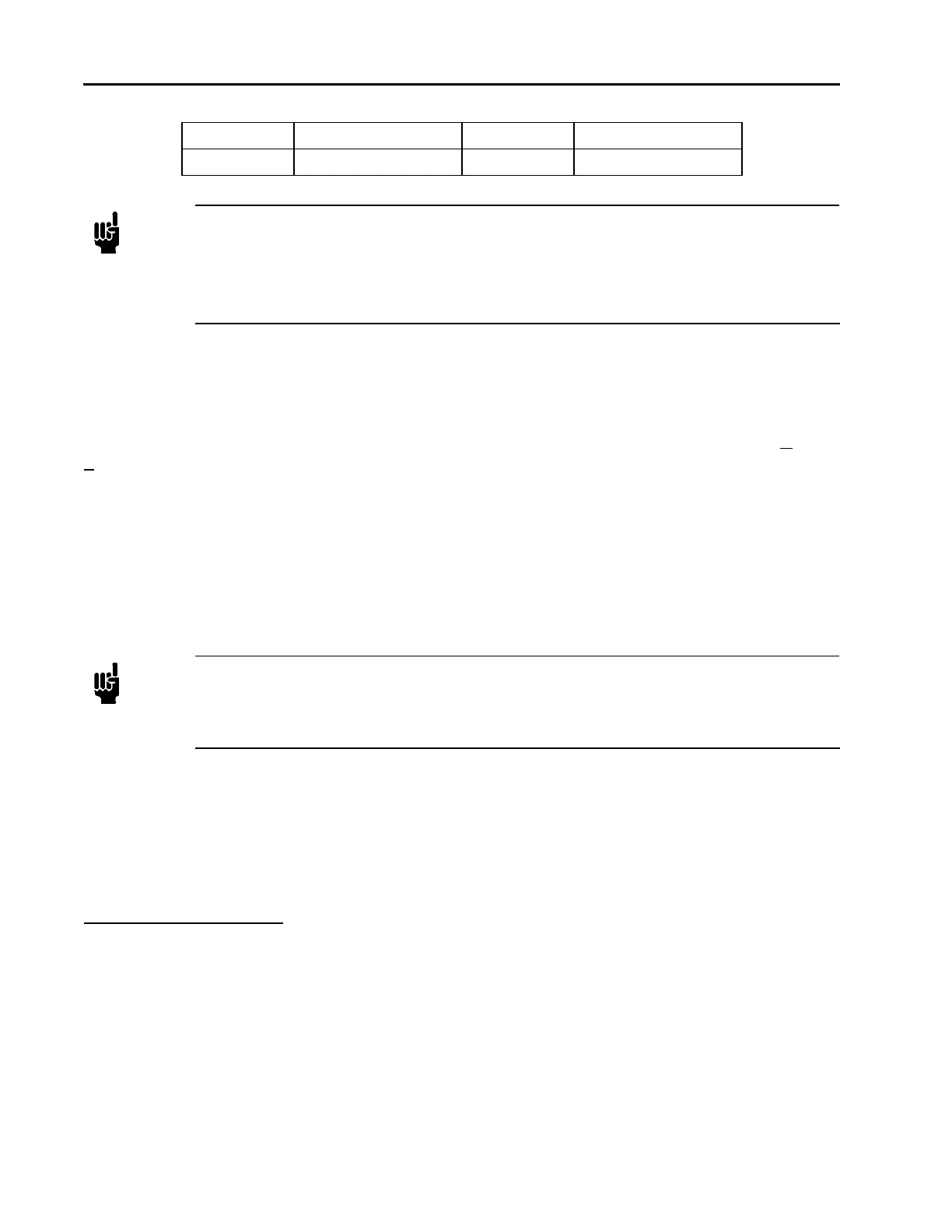

24

20 0.1333 21 20

22 200 23 0.001

Note

1. Pressure readings are reported as a percentage (%) of full scale (FS), where full scale is

the sensor range shown in Table 7.

2. For example, if the actual pressure is 10 Torr for a 10 Torr FS unit, the device reports a

pressure value of 100 (for 100%). If the pressure is 10 Torr for a 100 Torr FS unit, the

device reports a pressure value of 10 (for 10%).

To check the sensor range of your unit, issue the request:

R 55 for the Low range sensor

R 33 for the High range sensor

The controller responds with the message [Ex value], where x corresponds to either ‘H’ or ‘L’ for H

igh or

L

ow sensor range and value corresponds to a valid sensor range shown in Table 7.

If the Low range sensor has a range of 100 Torr, an example response is:

EL 08

To change the Low range to 5 Torr, enter:

EL 05

To change the High range to 1000 Torr, enter:

EH 10

Note

The sensor range of the High Channel MUST be greater than the sensor range of the low

channel. Also, you cannot successfully change the value of the high channel to a value that is

greater than the current low channel value. It may be necessary to change to low channel

range first to a value that is lower than the desired high channel range.

Alternatively, on code version 01.02.25 and newer, the commands SHRx and SLRx can be used.

Where x is the value of the pressure sensor.

Use RHR and RLR to report the high range and report the low range respectively.

Reported value is always in Torr. Maximum value is 10,000 Torr..

Chamber Pump Speed

Overview

There are three pump speed curves available in the 1.2.x version of software. Initially, all three curves will

have the same value. All curves are non-volatile.

Curve 1 is the factory default curve.

Curve 2 is the learned curve. A system LEARN writes its data to the learned curve (see below).

Curve 3 is the custom curve. This location is used for application specific pump speed curve.

Curves 2 and 3 are writable over the serial and DeviceNet interface.

Loading...

Loading...