11

Need help or have any questions? Call us at 1-714-963-0329 or send us an Email at service@globalhobby.net

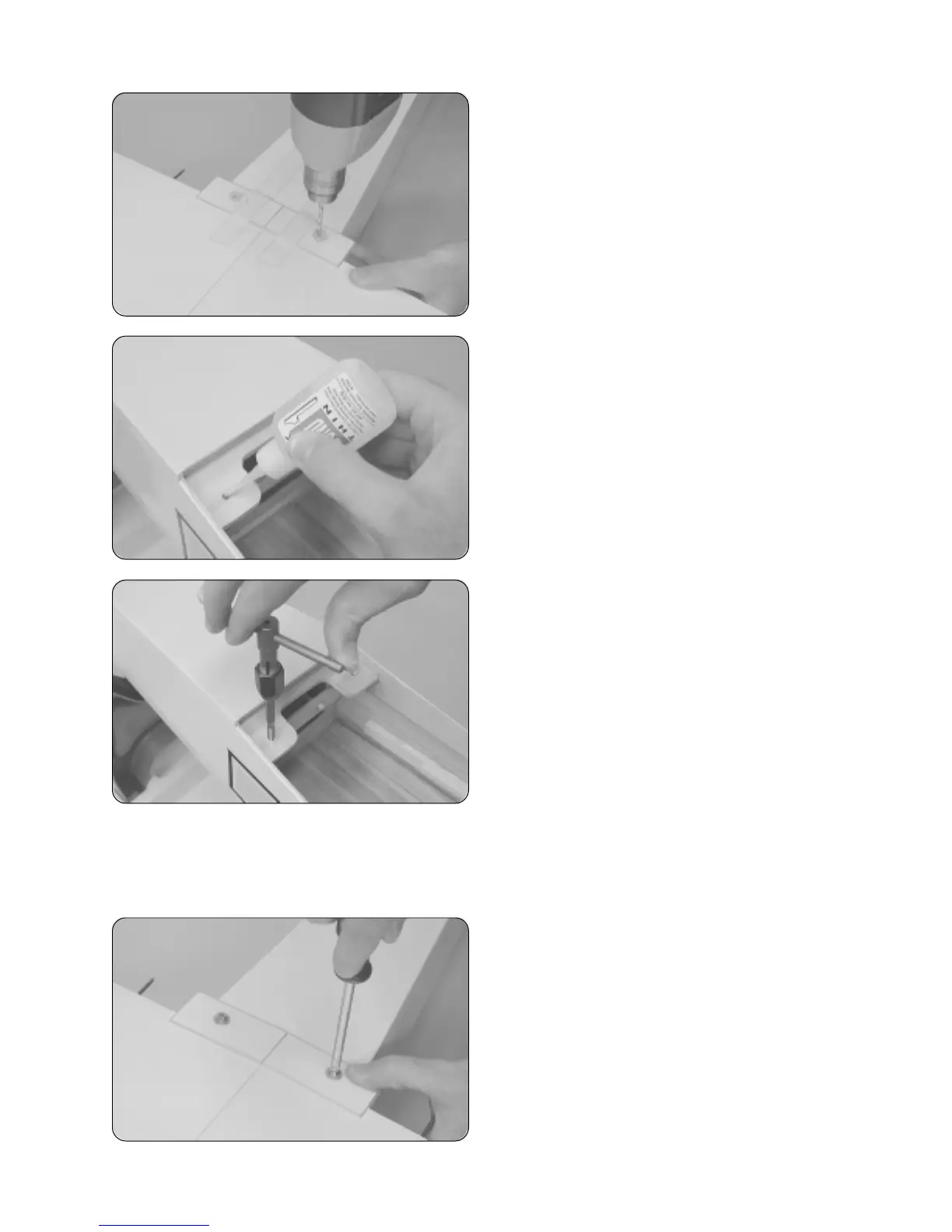

❑ Using an 5/32" diameter drill bit, drill two holes into the

wing and through the plywood wing hold-down block inside

the fuselage. Locate one hole in each wing panel, 1-3/4" out

from the centerline and 5/8" in front of the trailing edge.

IMPORTANT Drill the two holes perpendicular to the bottom

surface of the wing.

❑ Remove the wing from the fuselage and set it aside.

❑ Carefully apply several drops of thin C/A into both holes

in the wing hold-down block and allow the C/A to dry completely

before proceeding.

WARNING Let the C/A dry before proceeding to tap the

holes. If you don't, the C/A will clog the tap badly and ruin

the threads.

❑ After the C/A has fully cured, carefully tap the two holes

using a 5mm tap. Work slowly, being careful not to damage

the new threads you've just cut.

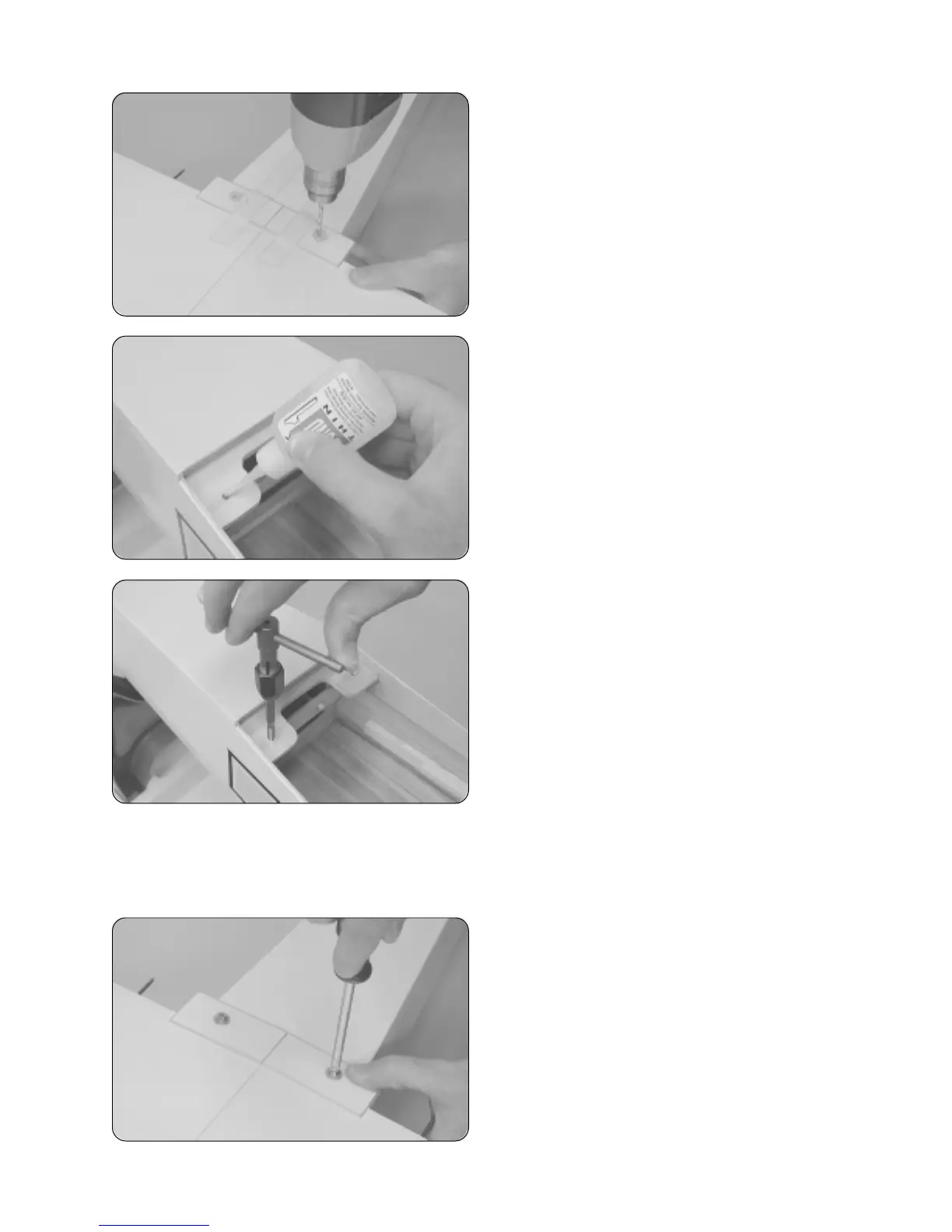

❑ After you're done tapping the threads, apply a couple of

small drops of thin C/A into the holes and let it soak in. Allow

the C/A to completely cure before proceeding.

IMPORTANT Do not omit this procedure. The C/A will

strengthen the threads and help prevent them from being

stripped out over time.

Step 3: Mounting the Wing

❑ Using a 13/64" diameter drill bit, enlarge only the two wing mounting holes in the wing, so the wing hold-down bolts will

slide through without binding.

❑ Set the wing back into the wing saddle and realign it.

❑ Secure the wing into place using two 5mm x 40mm

machine screws and two 5mm flat washers.

☞

Don't overtighten the screws. You don't want to crush

the wing.

Loading...

Loading...