30

Visit our website at http://modeltech.globalhobby.com or for Customer Service at http://globalservices.globalhobby.com

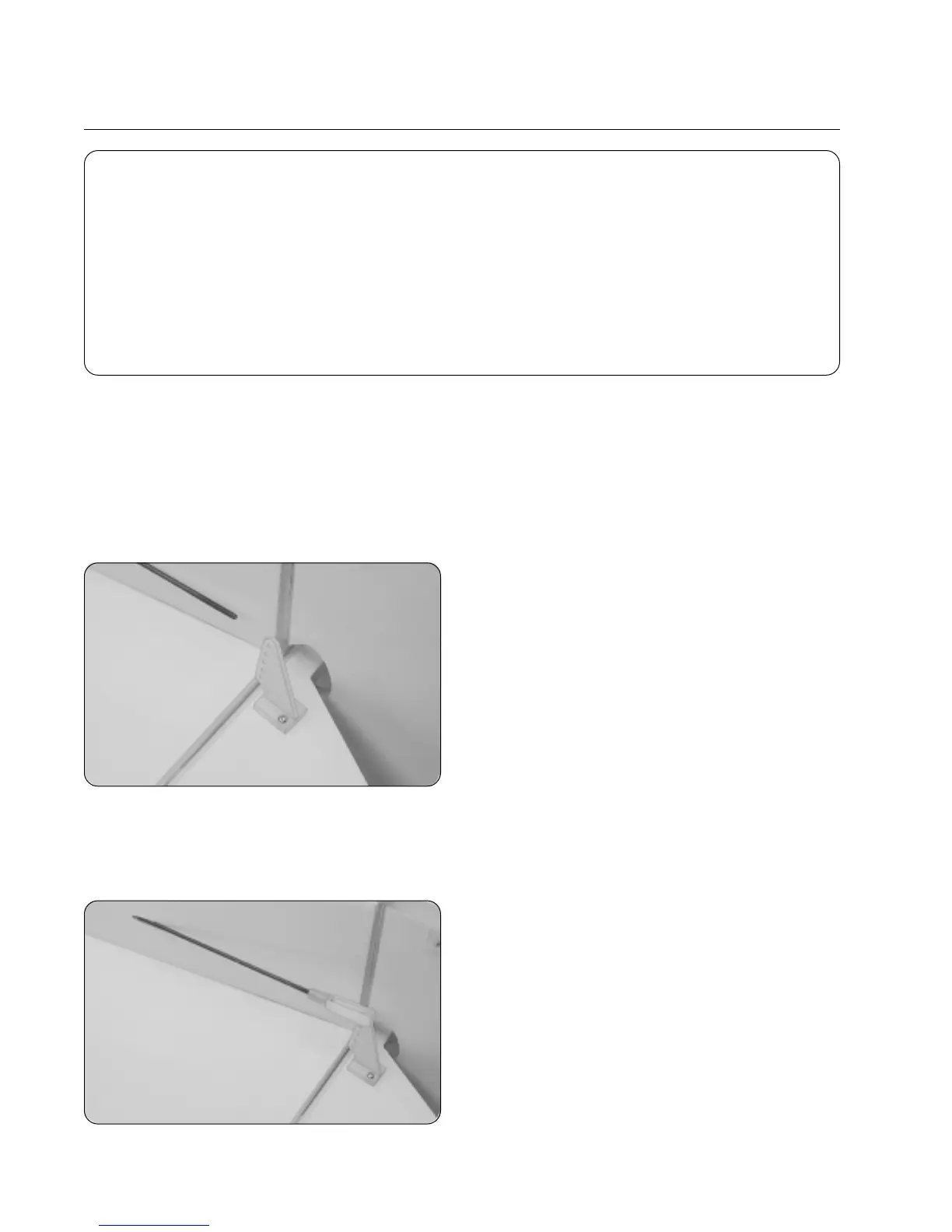

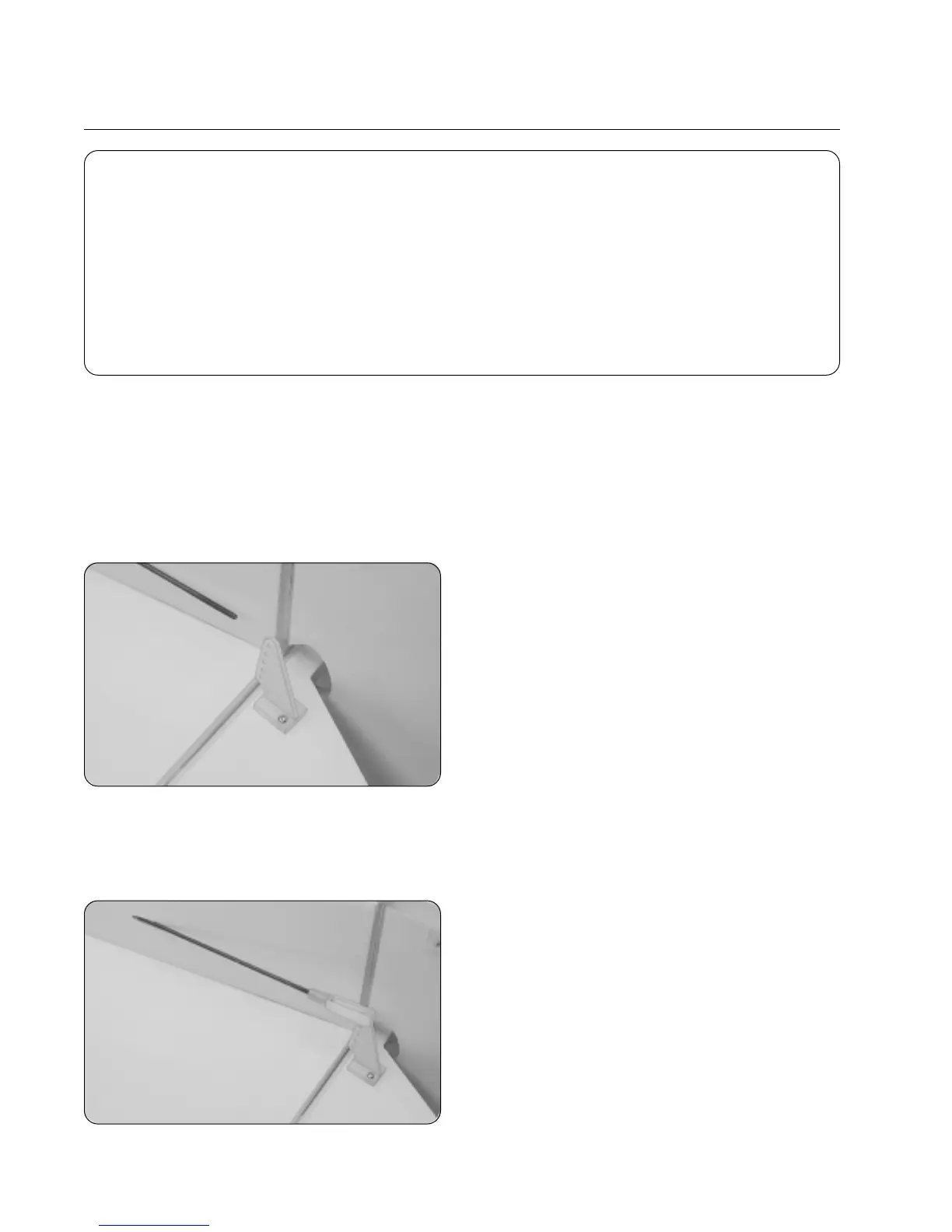

❑ Position one nylon control horn onto the bottom of the

elevator, aligning the control horn with the pushrod wire. The

centerline of the control horn should be about 5/8" out from

the side of the fuselage.

❑ Angle the control horn about 1/16" toward the fuselage

side so it will line up better with the pushrod wire and adjust the

control horn so that the clevis attachment holes are directly

over the hinge line.

❑ Mark the positions of the control horn mounting screws, then remove the control horn and set it aside.

❑ Drill the holes through the elevator for the mounting screws using a 5/64" diameter drill bit.

❑ Install the control horn and backplate using two 2mm x 20mm machine screws, being careful not to overtighten them.

❑ Thread one clevis onto the pushrod wire and snap it into

the outermost hole in the control horn.

☞

Hold the pushrod wire with a pair of pliers to prevent it

from turning while installing the clevis.

❑ # 1 Phillips Head Screwdriver

❑ Wire Cutters

❑ Needle Nose Pliers

❑ Excel Modeling Knife

❑ Electric Drill

YOU'LL NEED THE FOLLOWING PARTS FROM THE KIT:

❑ (2) 31" Threaded Wires

❑ (2) Nylon Control Horns w/Backplates

❑ (4) 2mm x 20mm Machine Screws

SECTION 17: ELEVATOR & RUDDER CONTROL SYSTEM INSTALLATION

❑ (2) Nylon Clevises

❑ (2) Nylon 90º Snap Keepers

YOU'LL NEED THE FOLLOWING TOOLS AND SUPPLIES:

❑ 5/64" Drill Bit

❑ Ernst Airplane Stand

❑ Ruler

❑ Pencil

❑ Masking Tape

Step 1: Installing the Elevator Pushrod Assembly

❑ Using a modeling knife, cut away and remove the covering material from over the elevator pushrod exit hole in the right

side of the fuselage. The hole is located 4-1/4" in front of the rudder hinge line and 7/8" below the horizontal stabilizer.

❑ Slide one 31" long pushrod wire (plain end first) into the preinstalled pushrod housing in the fuselage side.

❑ Use a couple of pieces of masking tape to hold the elevator centered.

Loading...

Loading...