24

Visit our website at http://modeltech.globalhobby.com or for Customer Service at http://globalservices.globalhobby.com

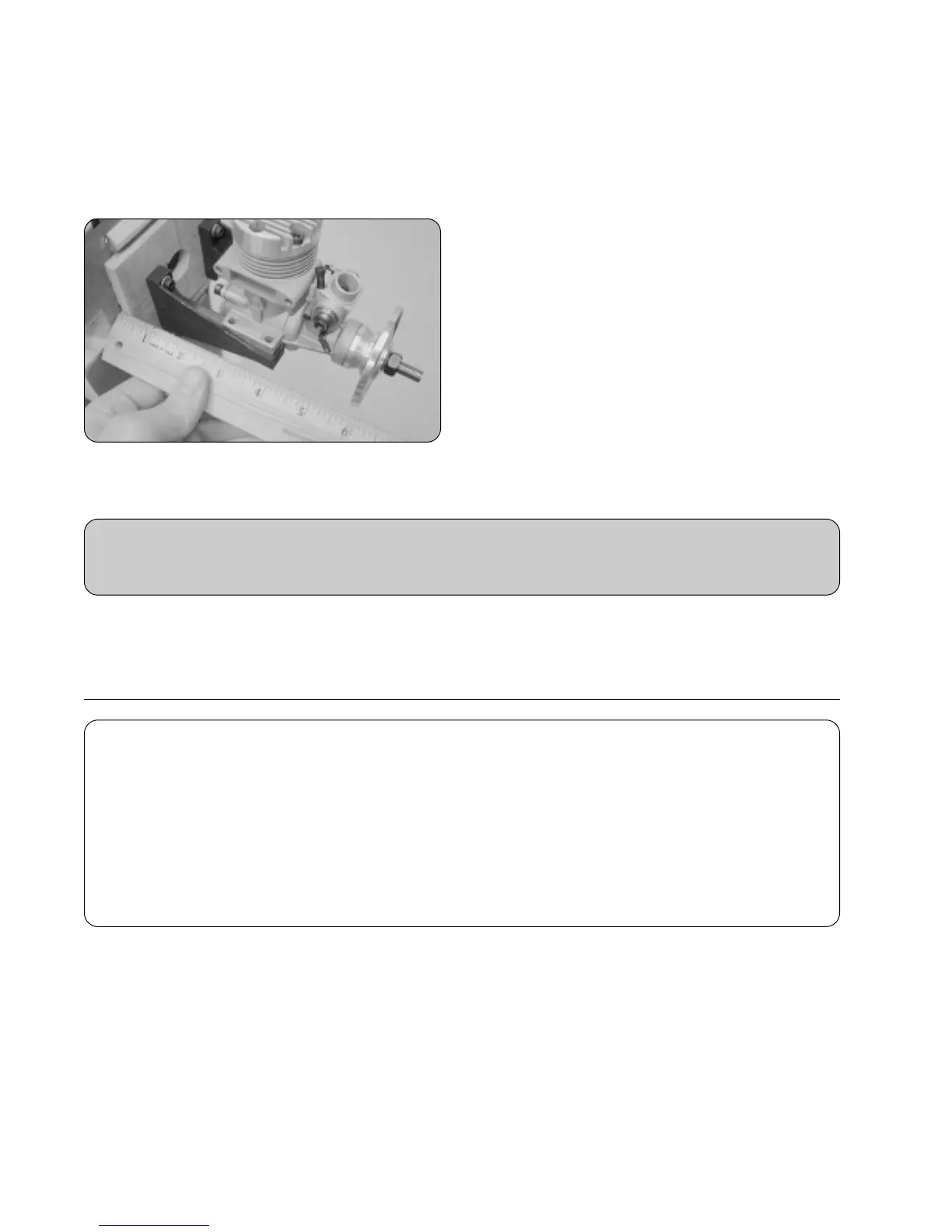

❑ Using a ruler, measure the distance from the firewall to

the back of the spinner backplate (front of the thrust washer).

Adjust the depth of the engine so the measurement is 5-7/8".

IMPORTANT If you're using a 1.08 or larger engine, the

distance from the firewall to the front of the thrust washer

should be 5-3/8".

☞

Measure from the firewall, even if you're using the

plywood spacer. Do not measure from the front of the spacer.

❑ Slide your spinner's backplate onto your engine and secure it in place using your engine's prop washer and nut.

❑ Set the engine onto the engine mounting beams.

❑ Using a pencil, mark the locations of the engine mounting holes onto the mounting beams. Remove the engine

and drill the holes through the beams using an 11/64" diameter drill bit. Be careful to drill the holes straight down and

not at an angle.

IMPORTANT Before mounting your engine in the next procedure, drill a 7/64" diameter hole through the firewall

for the throttle pushrod wire. Drill the hole near the side of the fuselage so it does not interfere with the fuel tank

when it's installed later. We located the hole 2" up from the bottom of the fuselage and 1-1/8" in from the side of the fuselage.

❑ Install the engine using four 4mm x 30mm socket-cap screws, eight 4mm flat washers and four 4mm lock nuts.

❑ # 1 Phillips Head Screwdriver

❑ Excel Modeling Knife

❑ Scissors

YOU'LL NEED THE FOLLOWING PARTS FROM THE KIT:

❑ (1) 360cc Fuel Tank

❑ (1) Large Diameter Metal Plate

❑ (1) Small Diameter Metal Plate

❑ (1) Rubber Stopper

SECTION 14: FUEL TANK ASSEMBLY & INSTALLATION

❑ (1) Fuel Pick-Up "Clunk"

❑ (1) 3mm x 20mm Machine Screw

❑ (1) Silicon Fuel Tubing

❑ (2) Aluminum Tubing

YOU'LL NEED THE FOLLOWING TOOLS AND SUPPLIES:

❑ Ernst Airplane Stand

❑ Ruler

❑ 220 Grit Sandpaper w/Sanding Block

Step 1: Assembling the Rubber Stopper

❑ Using 220 grit sandpaper, carefully smooth and deburr each end of the two aluminum tubes. This will prevent the fuel

tubing from being accidentally cut when it is installed later.

❑ Push the two aluminum tubes through the rubber stopper. Slide the large diameter metal plate over the tubes at the

front of the stopper and slide the small diameter metal plate over the tubes at the rear of the stopper.

Loading...

Loading...