Page 10

5. Apply a film of grease to the splines on the inside of the

gear balI (10). Install gear ball on connecting rod (38), with

counter-bored end (end without splines) first on connecting

rod. Gear ball should slide freely against shoulder on

connecting rod. Place lock nut (9) on connecting rod and

tighten against gear ball. Apply grease to spherical surfaces

and teeth of gear ball.

6. Apply grease to the teeth of the ring gear (8), and slide

ring gear onto the gear ball. When ring gear is in place,

keyways should be facing the lock nut end of connecting rod.

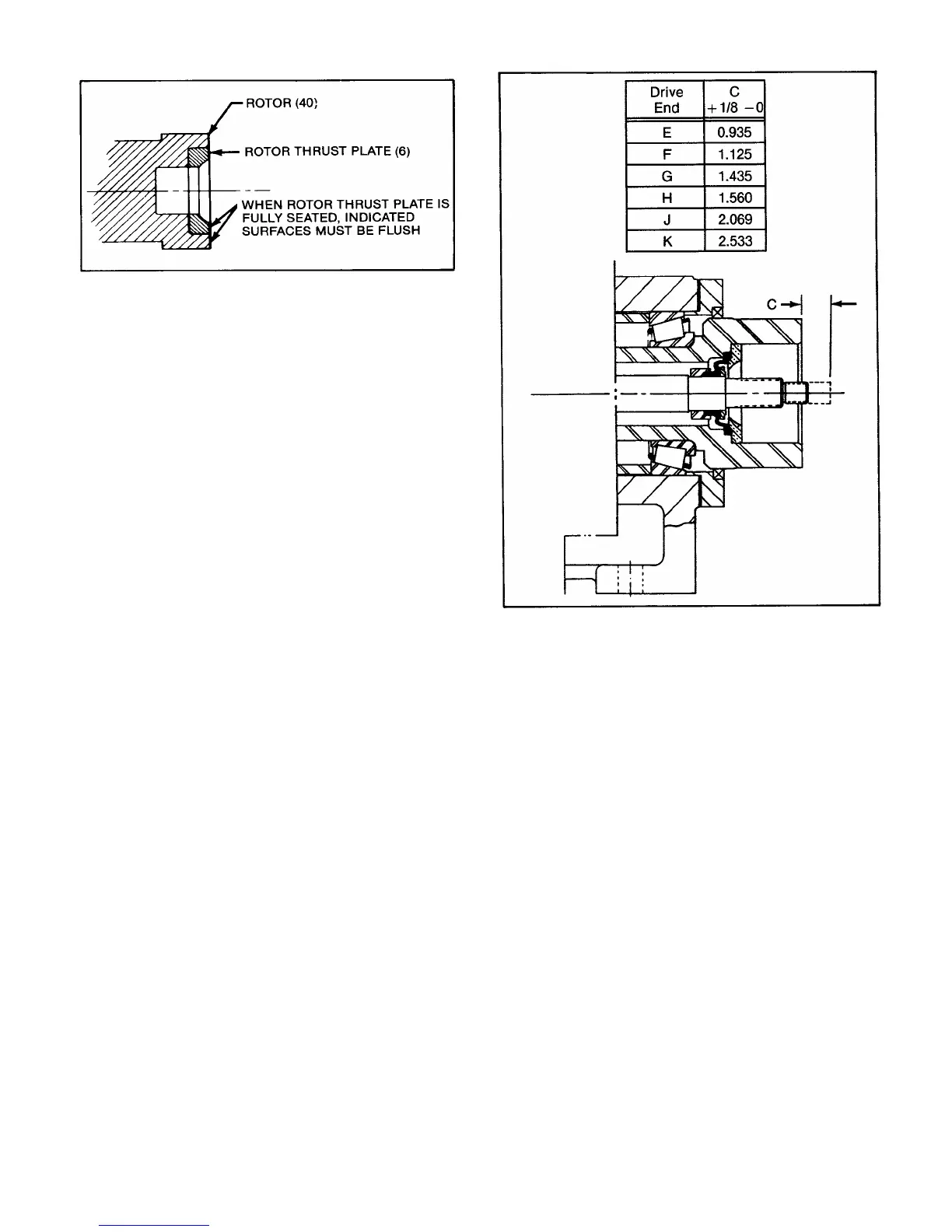

7. Apply a thin coating of grease to the spherical surface

of the thrust plate (6) already installed in the rotor head. Fill

the recessed area in the rotor head with grease.

8. Slide the gear joint shell (39) over the connecting rod

and assembled gear joint components, being careful to seat

the outside diameter of the gear joint seal (13) in the end of

the gear joint shell (39). The two tapped holes in the gear

joint shell should be in line with one of the keyways in the

ring gear.

9. Place keys (7) in the keyways in the ring gear. Check to

insure the tapped holes in the side of the gear joint shell are

aligned with one of the keyways.

10. Align the keys in the ring gear with the keyways in the

rotor head. Slide assembled gear joint shell onto the rotor

head, checking to be sure the keys are properly engaged in

the rotor head and ring gear. The shallow hole in the rotor

head should be aligned with the first threaded hole in the

outside of the gear joint shell. Thread the setscrew (S) into

the threaded hole in the shell until light contact is made with

the hole in the rotor head.

11. Place O-ring (41) into step in gear joint shell. Align

holes in head ring (42) with six threaded holes in end of gear

joint shell and install stainless socket head screws (T).

Tighten the six socket head screws evenly, checking to in-

sure O-ring (41) remains in place. When tightened properly,

a small gap of a few thousandths of an inch may exist be-

tween the shell (39) and head ring (42).

12. Excess grease in the assembly will be purged from the

vent hole while the socket head screws are tightened.

Tighten the setscrew (S) in the shell. Move the free end of

the connecting rod in a circular motion to assure that the joint

is free and assembled properly. This will also help to purge

excess grease from the assembly.

13. Install the stainless steel pipe plug (C) in the

second hole in the shell and tighten.

4-31. Rotor/Stator to Drive End Assembly

1. If not already in place, slip stator clamp rings (36) on

both ends of stator (30), and install retaining rings (35) in

grooves provided on both ends of stator.

2. Place stator gasket (34) in recess in end of suction

housing:

a. On J335 model, stator gasket (34) will be installed

in recess in adapter housing (25B).

b. On F012, G022, H036, and K115 models, stator

gasket (34) will fit recess in adapter flange (25A) and adapter

flange gasket (24A) will fit recess in suction housing.

3. Move the rotor/stator/connecting rod assembly in po-

sition, and insert connecting rod through the suction housing

and drive shaft. Align stator with bore in suction housing, and

slide stator in place, checking to insure that stator gasket

(34) remains properly positioned.

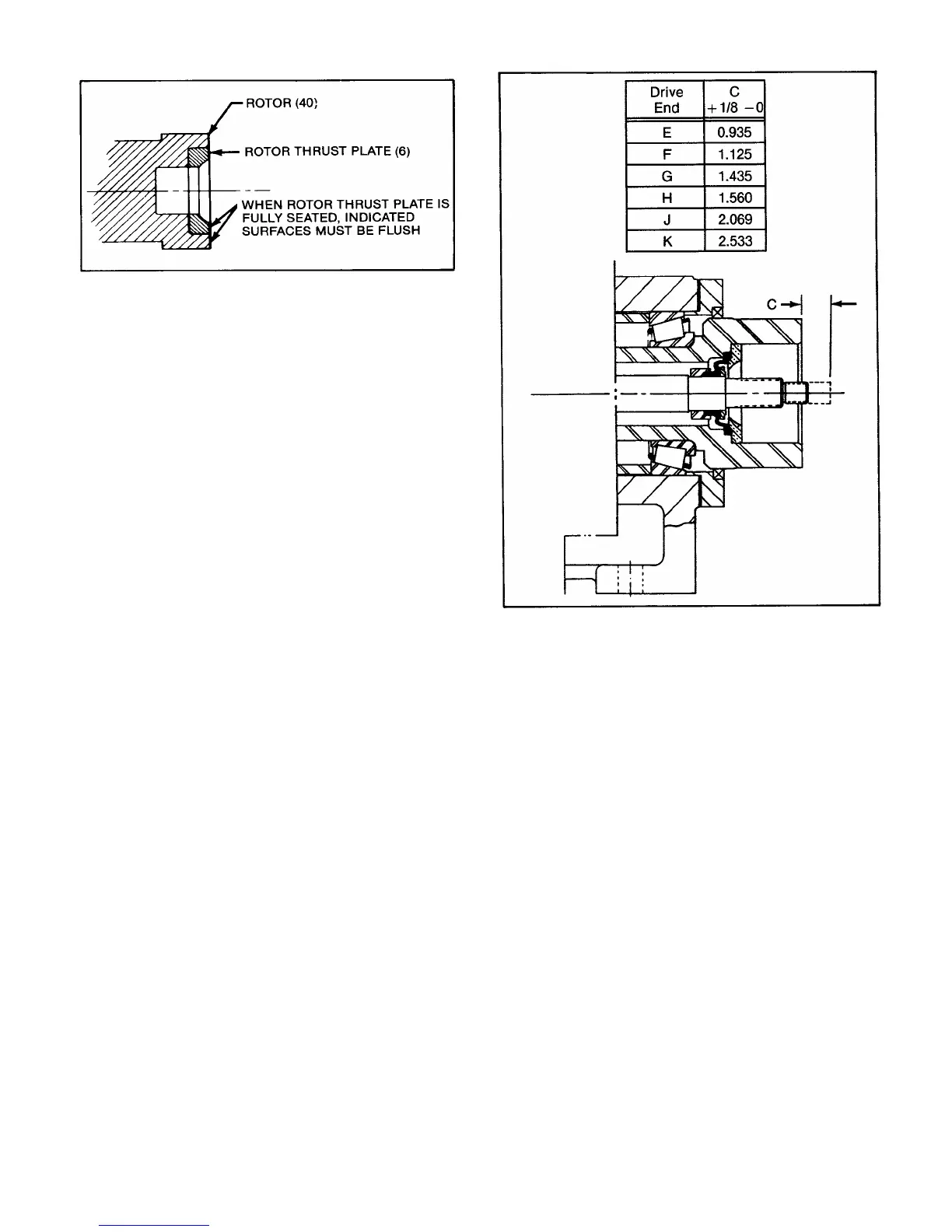

4. Check the dimension “C” between the end of the con-

necting rod and face of the drive shaft as shown in fig. 4-7.

For proper assembly of the drive end gear joint, this

dimension should be no less than that shown in column C,

and should not exceed the amount in column C by more than

1/8 inch. Reposition rotor/stator assembly in or out of suction

housing as required to achieve the proper dimension.

Figure 4-6. Rotor Thrust Plate Seating Detail

Figure 4-7. Gear Joint Installation

Loading...

Loading...