Page 4

3-1. OPERATION

3-2. INITIAL CHECK

Before putting the pump into operation, the following

items should be checked to ensure that each piece of

equipment is installed correctly:

— Pump, driver, coupling or sheave alignment.

— Electrical connections.

— Gauges and other instruments.

— Water flush connection to the stuffing box.

— Pump rotation. Normal rotation is indicated on the

nameplate on the bearing housing.

— All valves should be open on both suction and dis-

charge sides of pump.

CAUTION: This is a positive displacement pump. Do not

operate it against a closed valve.

3-3. START-UP

CAUTION: DRY OPERATION IS HARMFUL TO THE

PUMP! Never allow the pump to operate with-

out liquid, as dry operation will cause prema-

ture wear of the stator and possible damage.

The stator is lubricated by the liquid, which

is pumped.

1. Before operating the pump for the first time, fill it with

liquid (the drain plug hole on the suction housing may be

used for filling). If the liquid to be pumped is highly viscous,

dilute it before filling the pump. The liquid fill-up will lubricate

the stator for the initial start-up.

2. Once the pump has been filled with liquid, check for

direction of pump rotation by momentarily starting and

stopping the drive. Check rotation arrow on pump nameplate

for correct rotation.

3. In suction lift applications, when water flush is not

utilized it may be necessary to replace the zerk fittings at the

stuffing box (in suction housing) with pipe plugs to prevent

loss of prime due to air leakage.

4. If applicable, turn on the water to the packing.

5. Start pump.

3-4. PACKING LEAKAGE

A packed stuffing box is designed to control leakage, not

stop it completely. Leakage is generally necessary to reduce

friction and dissipate heat. The amount of leakage necessary

will depend on the fluid pumped, the installation, and

pump.speed and type. Refer to Section 4-3 for packing

adjustment.

Moyno 2000 pumps have been designed for minimum

stuffing box leakage when properly maintained. If leakage

cannot be tolerated, then a mechanical seal should be used.

4-1. MAINTENANCE

Note: In this section, the first reference to each pump part

will be followed by a number or a letter in parentheses

( ). These numbers and letters are those used to

identify the pump parts and hardware items in the

fold-out Exploded View (Figure 4-8).

4-2. GENERAL

The Moyno 2000 pump has been designed for a minimum

of maintenance, the extent of which is routine adjustment

and lubrication of packing. The pump is one of the easiest

to work on, in that the main elements are very accessible

and require few tools to disassemble.

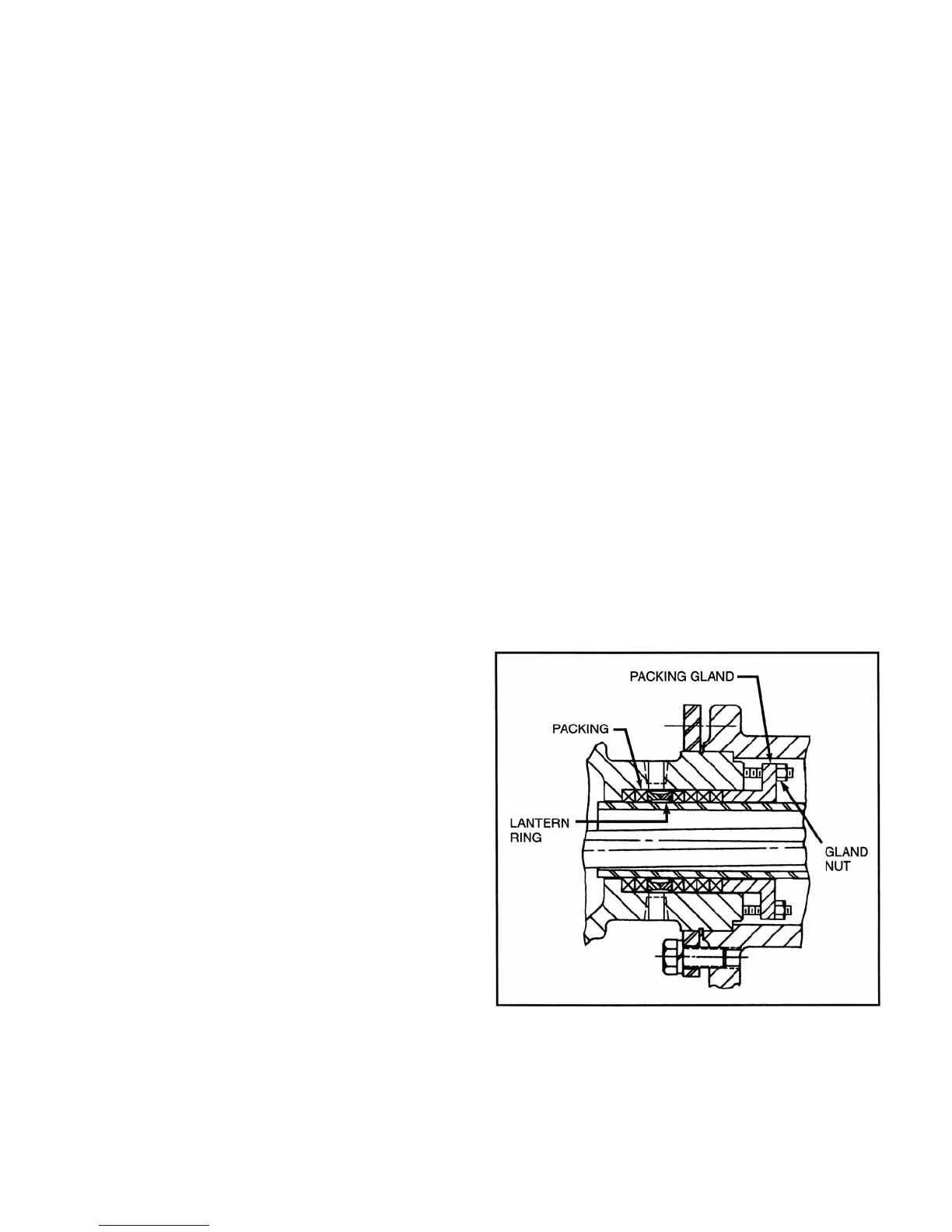

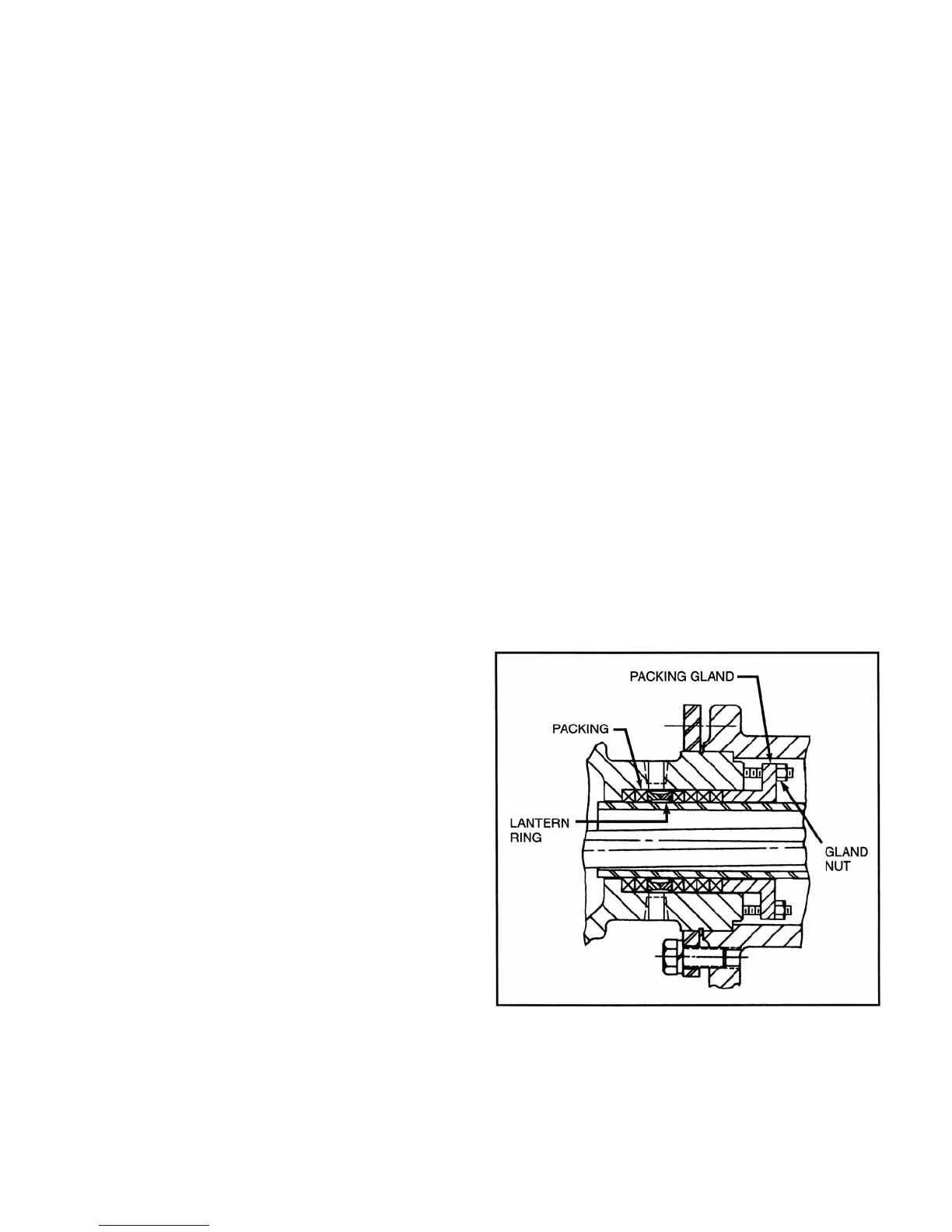

4-3. PACKING ADJUSTMENT

Packing gland nuts should be evenly adjusted so they are

little more than finger tight. (See fig. 4-1.) Over-tightening the

packing gland may result in premature packing failure and

possible damage to the shaft and gland.

When packing is new, frequent minor adjustments during

the first few hours of operation are recommended in order to

compress and seat each ring of packing evenly.

1. Upon initial start-up of the pump, adjust the gland nuts

for a leakage rate of 1-2 drops per second until the packing

has seated and adjusted to the operating temperature

(approximately 10-15 minutes).

2. If leakage is excessive after 15 minutes of operation,

tighten the gland nuts until a desired leakage rate is ob-

tained.

CAUTION: Do not tighten until zero leakage is obtained.

Over-tightening of the packing gland may

result in accelerated wear on the packing and

damage to the shaft. In those situations

where no packing leakage can be tolerated,

consult your Moyno Authorized Service

Representative.

Figure 4-1. Cross Section of Stuffing Box

Loading...

Loading...