4-16. INSPECTION

4-17. Bearings. After cleaning, rotate bearings very slowly

under hand pressure to feel for smoothness and even action.

Never spin a dry bearing. Check for cracks, galling, pitting,

burrs, etc. Replace bearing if there is any doubt concerning

complete serviceability.

4-18. Drive Shaft. Inspect drive shaft (14) for scoring, burrs,

cracks, etc. Replace as necessary.

4-19. Seals. It is sound practice to always replace grease

seals (1 and 19) whenever drive shaft and tapered roller

bearings are removed. Apply Locktite 690 to outside

diameter of both grease seals.

4-20. Packing. It is sound practice to always replace pack-

ing (22) whenever the pump bearing housing is

disassembled.

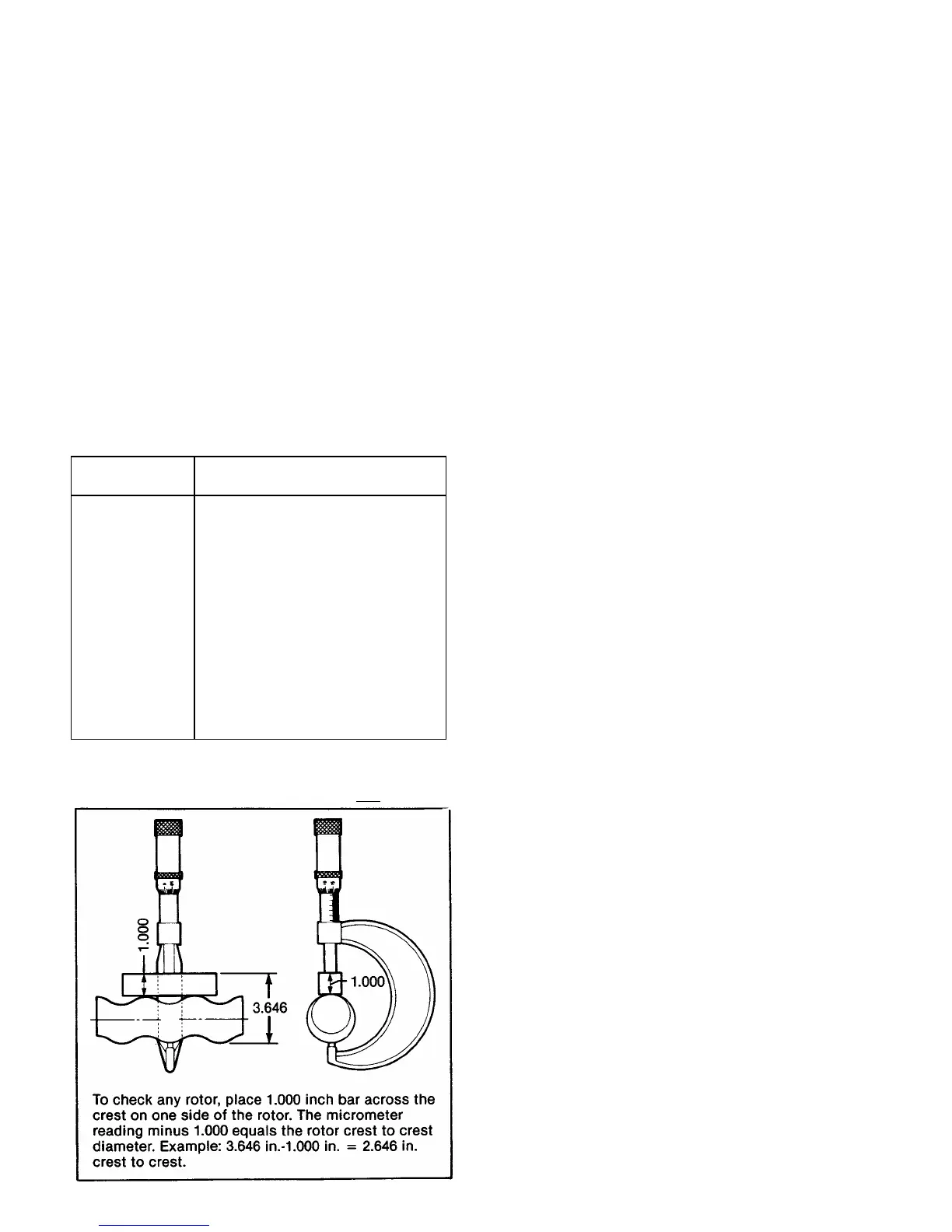

4.21. Rotor.

1. To check for excessive wear of rotor (40), measure the

rotor crest-to-crest diameter (see fig. 4-4) and compare with

the following chart:

Rotor

Capacity

Standard

*Crest to Crest Dia. (inches)

008 2.772 + .000/—.004

012 2.676 + .000/—.004

022 3.425 + .000/—.004

036 4.015 + .000/—.004

050 4.015 + .000/—.004

065 4.906 + .000/—.004

090 4.906 + .000/—004

115 5.709 + .000/—.004

175 6.584 + .000/—.004

335 5.800 + .000/—.005

345 7.260 + .000/—.004

620 7.128 + .000/—.005

800 7.658 + .000/— .004

* These dimensions are applicable for AAA trim codes only.

Note: The rotor is designated by the third, fourth and fifth

numbers in the Model Number, i.e., 1G065

G1.

2. If the measured crest to crest diameter is within 0.010

inch of the standard value and is free of deep nicks, gouges,

or other surface defects, the rotor is re-usable.

3. Rotors with crest to crest values 0.011 to 0.050 inch

under the standard values should be replaced. These rotors

can be renewed by chrome plating to standard dimensions

provided that:

a. The key slots are not excessively worn.

b. The rotor surface is not cracked, pitted or deeply

grooved (1/32 inch or more).

c. The base surface metal is not pitted or corroded.

4. Rotors may be sent to Moyno or any other competent

plating shop. Rotors should be stripped and replated to

standard dimensions, then buffed.

4-22. Stator. A worn stator may appear pitted and gouged,

or may appear smooth similar to when new. Performance is

the best measure of rotor to stator fit. If unable to measure

performance adequately, suspected stator wear can be

evaluated by a Moyno sales or factory representative.

4-23. All Other Parts. Check for cracks, excessive wear,

damage to threaded holes, burrs, etc. Replace as necessary.

Replace O-rings and all gaskets at each disassembly and

reassembly.

4-24. ASSEMBLY

The Moyno 2000 pumps are reassembled in the reverse

order of dismantling. The following suggestions are offered:

1. While pump is dismantled, check all gaskets, seals,

packing, and O-rings. Replace all worn items. It is recom-

mended that the gear joint seals (13), gear joint O-ring (41),

and drive shaft O-ring (5) be replaced each time either of the

gear joints is disassembled.

2. During the assembly process, cleanliness is important.

To avoid premature failure, bearings and gear joint compo-

nents must be handled with care and kept clean.

4-25. Lubrication During Assembly

Note: The bearings are lubricated at the factory, and will

only need to be re-lubricated when the shaft/bearing

assembly is completely removed from pump.

1. Bearings. Pack bearings after installation on shaft

(Section 4-28). Lubricant should be packed around all of the

rollers and should completely cover the faces of the races.

The void inside the spacer between the bearings should be

filled approximately half way with lubricant.

2. Gear Joints. Both gear joints should be packed with

lubricant during assembly (Sections 4-30 and 4-32). DO

NOT use zerk fittings to lubricate gear joints after assembly.

The pipe plugs (C) in the drive shaft head, drive shaft, and

gear joint shell are vent plugs and MUST BE REMOVED

during assembly of the gear joints to allow excess lubricant

to vent from the gear joints.

3. Packing. Lubricate packing rings during assembly. Ad-

ditional grease can be added after assembly through the

zerk fittings installed in the side of the stuffing box.

Page 7

Figure 4-4. Measuring Rotor Dimension

Loading...

Loading...