Page 26

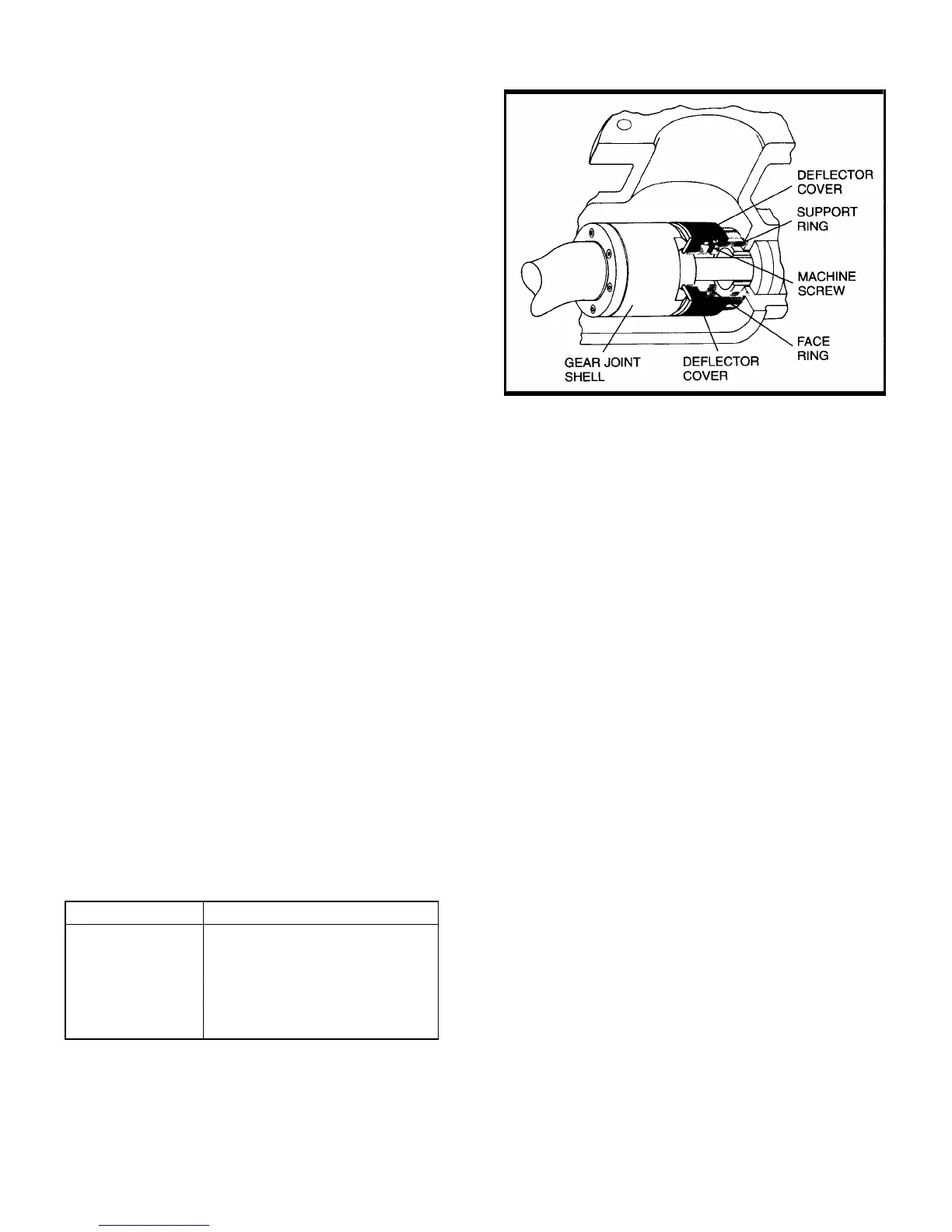

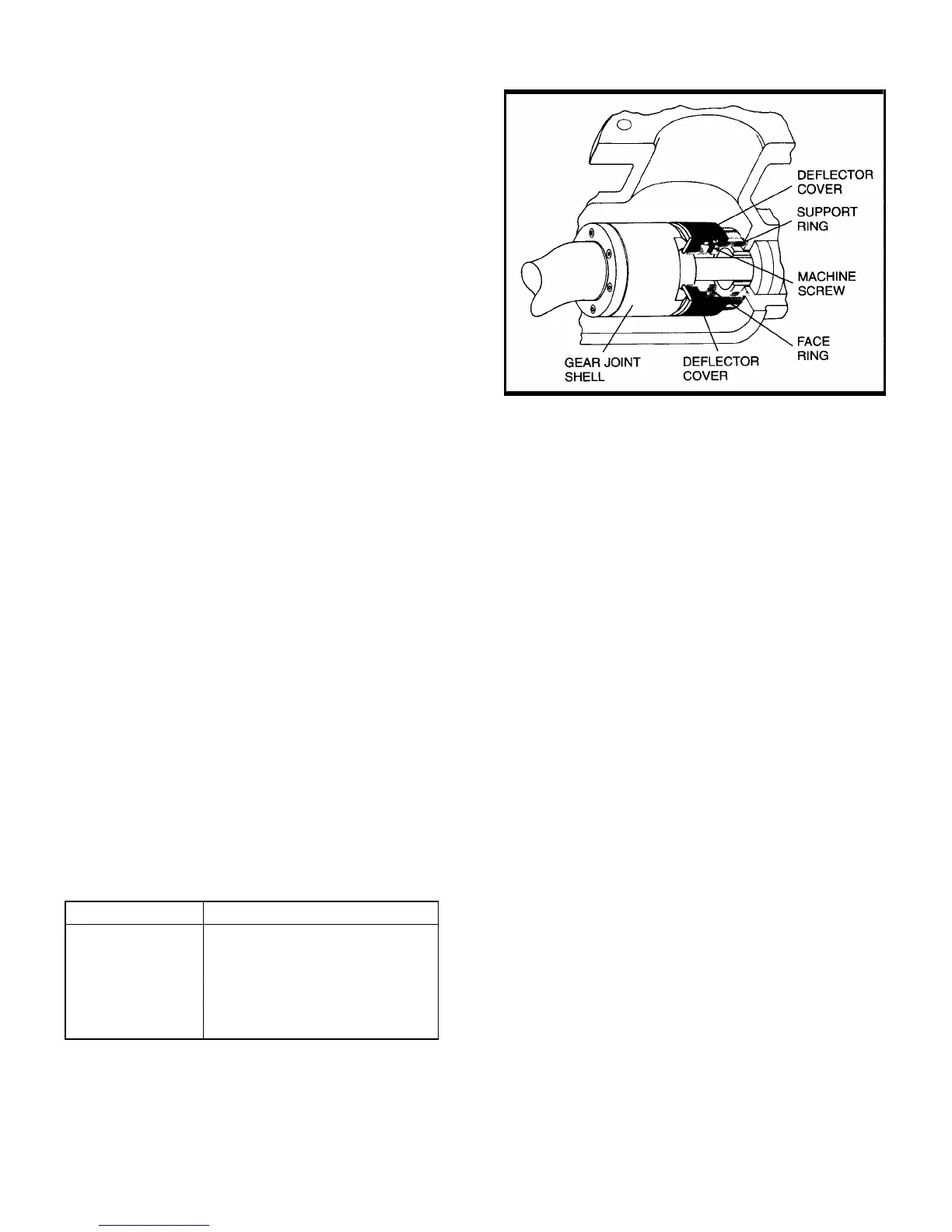

4-49. FIBER DEFLECTOR OPTION

4-50. OPERATION

The Moyno Fiber Deflector is designed to prevent an accu-

mulation of rags and stringy material around the connecting

rod and rotor head area of your Moyno 2000 pump. The

Fiber Deflector eliminates the potential for equipment

damage and downtime due to blockage.

The Fiber Deflector operates in a similar way to an end

face-type mechanical seal. The stationary lip of the deflector

cover rides against a polished disk rotating with the gear joint

shell. The deflector cover does not seal fluid from entering

the drive shaft; it only shields debris from wrapping around

the connecting rod.

4-51. DISASSEMBLY/ASSEMBLY

A Moyno 2000 pump purchased from the factory and

equipped with a fiber deflector needs no adjustments. When

service becomes necessary, however, and you must

disassemble the pump, follow these steps for dismantling the

fiber deflector:

1. Remove the inspection plate and gasket.

2. Pull back the end of the deflector cover exposing the

two machine screws holding the face ring to the support ring.

Note: The two machine screws will be facing one of the two

inspection plates.

3. Loosen the machine screws and slide the face ring and

deflector cover away from the gear joint shell.

4. Disassemble the rest of the pump as described in this

manual.

5. After you completely reassemble the pump, slide the

face ring and deflector cover toward the gear joint shell until

the rubber lip of the deflector cover contacts the disk on the

gear joint.

6. Tighten the two machine screws and fold the end of the

deflector cover over the machine screws.

7. Reassemble the inspection plate gasket and inspection

plate.

4-52. PARTS LIST

Drive End Size Deflector Cover

E PE0595

F PF0595

G PG0595

H PH0595

J PJ0595

K PK0595

Figure 4-12. Fiber Deflector

4-53. FLUSH GLAND OPTION

4-54. GENERAL

The flushable packing gland allows packing leakage to be

conveniently flushed away from the pump, providing a clean,

safe environment and preventing potential damage to seals

and bearings. The gland is used in many waste treatment

and paper industry applications, where process fluid leakage

past compression packing and settling around the pump unit

cannot be tolerated.

Compression packing is designed to permit a controlled

leakage of process or flush fluid, not to stop it completely.

Leakage is necessary to reduce shaft friction and dissipate

heat. The flushable gland has inlet and outlet connections

that can be plumbed to a flush medium supply and flush

medium drain. As packing leakage enters the gland it is

flushed away to the drain.

The flushable packing gland is available for Moyno 2000

pumps, both in the “G1” flanged models and “G2” open

throat models. It can be installed on pumps with or without

shaft sleeves.

4-55. INSTALLATION

When retrofitting a pump that already has a standard

gland, follow these steps:

1. Remove the original packing gland halves.

2. Remove the packing and lantern rings.

3. Remove the gland studs.

4. Clean the surfaces of the drive shaft and stuffing box.

5. Install a new set of packing rings. See the following

table for the proper number of packing rings for your pump

size.

NOTE: Standard packing set includes 6 rings of packing.

If lantern ring is not used, 2 sets of standard packing

are needed to meet the packing quantity guidelines.

Loading...

Loading...