4-4. PACKING REPLACEMENT

When leakage can no longer be regulated by tightening

the gland nuts, remove and replace the packing. Replace as

follows:

1. Remove packing gland nuts (F), and slide gland (21)

and slinger ring (20) back along drive shaft (14).

2. Remove packing gland studs.

3. Use a pair of packing extractors (Figure 4-2) to remove

four packing rings (22), lantern ring halves (23) and two

additional packing rings (22).

Figure 4-2. Packing Removal Tool

3. Inspect surface of drive shaft for wear or grooves. If

shaft is worn through the chrome plating into the base metal,

or is badly scored or grooved it should be replaced.

4. If drive shaft is not worn, install two rings of packing, the

lantern ring halves, and four more rings of packing; lubrica-

ting them before installation with a good grade of packing

grease. Be sure to stagger the packing ring joints at 90°

increments. (See Section 4-26.)

CAUTION: Always use a proper packing tamper tool to

install packing. Do not use a pointed or sharp

tool, as damage to the packing material or

drive shaft could result. To assure proper

shaft lubrication, never use a one-piece

spiral wrap packing.

5. Replace packing gland (21) and secure with packing

gland nuts. (See fig. 4-1.)

6. Adjust packing per Section 4-3.

4-5. LUBRICATION

4-6. Bearings. The bearings are lubricated at the factory

and will only need to be re-lubricated when the shaft/bearing

assembly is removed from the pump.

4-7. Gear Joints. Both gear joints are packed with lubri-

cant during assembly, and will only need to be re-lubricated

when gear joints are disassembled.

4-8. DISASSEMBLY

Note: The following instructions cover ONE procedure for

disassembling all pump components. Major pump

components can be disassembled in various ways

since specific installation location limitations will

determine method of component removal.

4-9. Disconnect Pump

1. Flush the pump (preferably with clean water) to remove

the pumpage from the unit.

Page 5

2. Shut off pump.

3. Close suction and discharge valves.

4. Turn off flush water to packing or mechanical seal,

if used.

5. Disconnect power source.

6. Drain any fluid in pump by removing the drain plug or

inspection plate.

7. Remove inspection plate (32) and gasket (33).

4-10. Packing Removal

1. Shut off pump.

2. Complete Section 4-9, steps 3 - 6.

3. Remove gland adjustment nuts (F), gland studs (H) and

gland halves (21) from stuffing box.

4. Remove packing rings (22). This is best done by using

flexible packing extractors (see fig. 4-2). Use two extractors

simultaneously on opposite sides of each ring. Pull evenly.

5. Remove lantern rings (23) in similar fashion. Twist split

rings to remove from shaft.

6. Remove additional packing rings.

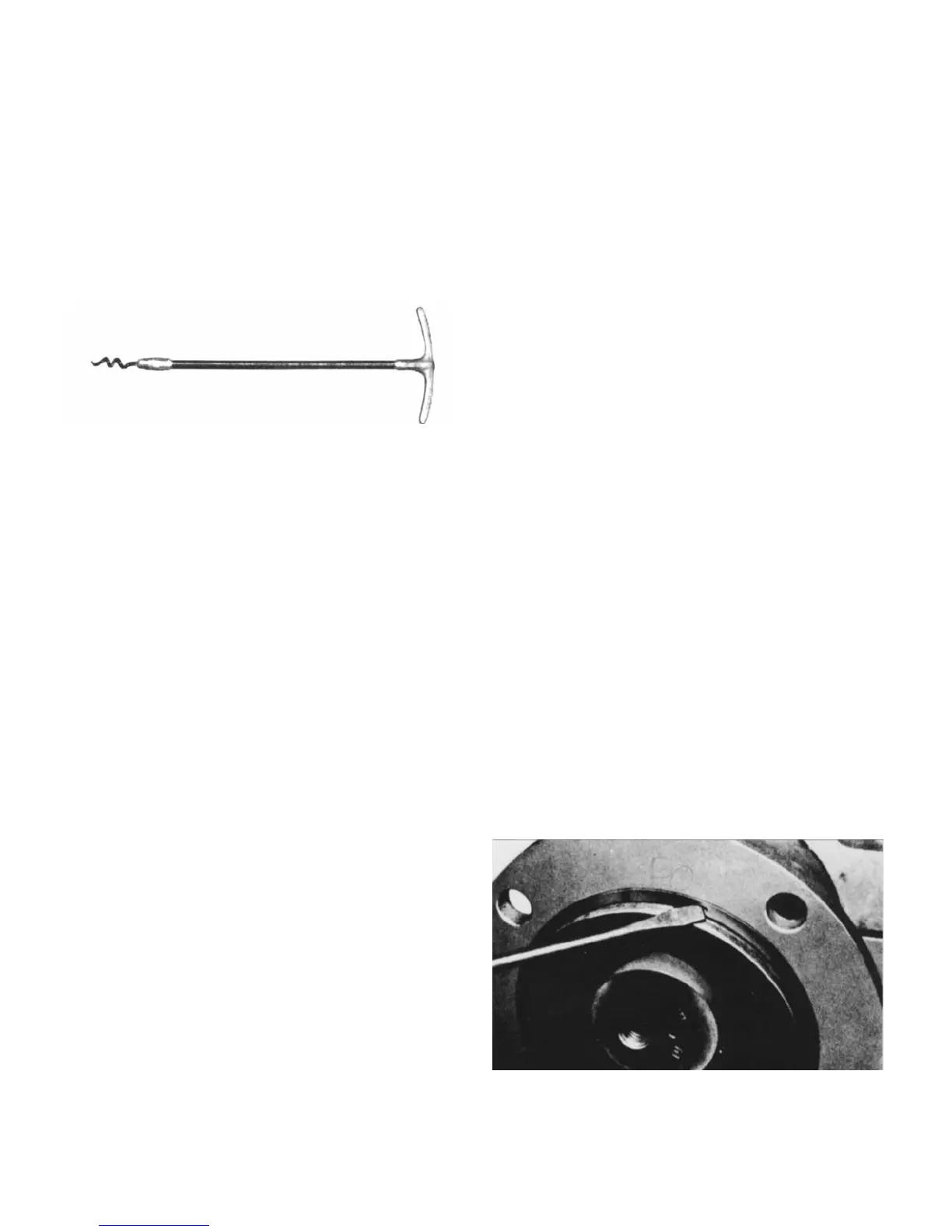

4-11. Stator Removal

1. Complete Section 4-9.

2. Remove section of discharge pipe attached to dis-

charge flange (37).

3. Remove top half of stator support (31).

4. Unbolt stator clamp ring (36A) from suction housing (29).

Pull stator off rotor (see note below). Remove stator

gasket (34). Use a screwdriver tip to carefully remove

stator retaining ring (35). (See fig. 4-3.) Remove stator

clamp ring (36) from stator (30).

Figure 4.3. Typical Retaining Ring Removal

Loading...

Loading...