Page 12

5. See OPERATION Sections 3-1 through 3-4 before

startup. Be sure all lubricants are in good condition.

4-38. Long Term Storage. If pump is to be in storage for

more than 6 months, perform the above short term storage

procedures plus the following:

1. Occasionally rotate the pump manually a few revolu-

tions to avoid a “set” condition of rotor in stator elastomer.

This will prevent hard starting and excessive torque require-

ments when pump is again put into operation.

2. Apply rust inhibitor to all unpainted cast iron and

machined carbon steel surfaces.

3. Remove drive belts if applicable.

4-39. PACKING SPECIFICATION

Standard packing on all Moyno 2000 pumps consists of

braided PTFE fibers impregnated with ultra-fine graphite.

Optional types of packing are available for food, high

temperature and other types of service. Consult your nearest

Moyno representative.

4-40. VARIATIONS OF STANDARD PARTS

The following are variations available for modifying pumps

to meet specialized pumping conditions. If the trim code of

your pump is other than “AAA,” contact your nearest Moyno

representative for clarification. Do not modify your pump with

any variation unless you have determined that it is

compatible with your application.

The three-character trim code is designed as follows. The

first character identifies any sealing variations, the second

character identifies any internal variations, and the third

character identifies any rotor variations.

Sealing Variation

Internal Variation A A A

Rotor Variation

The trim code “AAA” represents a pump with standard fea-

tures. Deviations from standard are to be indicated by

changing the appropriate character from the choices listed.

When two or more letters are combined, dashes are used to

separate the three areas of the trim code for clarity.

SEALING VARIATIONS

A — BRAIDED TEFLON & GRAPHITE PACKING, (Black)

Standard to all lines except Quick Disassembly

pumps. Optional on Quick Disassembly pumps.

C — BRAIDED TEFLON PACKING, (White) Optional

packing on all lines.

D — DOUBLE MECHANICAL SEAL, Optional on all

lines. Not offered on #2 “L” frame.

F — BRAIDED TEFLON FOOD GRADE PACKING,

(White) Standard on all Quick Disassembly pumps.

Optional on all other lines.

G — 100% GRAPHITE PACKING, (Gray) Optional to all

lines.

H — FLUSH PACKING GLAND

S — SINGLE MECHANICAL SEAL, Optional on all lines.

W — WATER FLUSH, Optional on all lines.

X — Special to application

INTERNAL VARIATIONS

A — Standard plated shaft

B — Non-plated shaft

C — Solid drive shaft configuration

E — Extension tube with extended auger

F — Extended drive shaft (for back stop or large pulley)

G — Ceramic coated drive shaft

K — Tungsten carbide coated drive shaft

M — Chromium carbide coated drive shaft

R — Fiber deflector

S — Shaft sleeve

X — Special to application

ROTOR VARIATIONS

A — Standard size with chrome plating

B — Non-plated (no plating)

C — Standard undersize

E — Standard oversize

G — Ceramic coating

K — Tungsten carbide coating

M — Chromium carbide coating

X — Special to application

4-41. Rotors identified on parts listing are standard size

with hard chrome plated surface. Other variations of rotor

size and finish may be ordered by selecting the standard

rotor part number and changing the last digit of the rotor

number as follows:

2 = Standard size, non-plated

3 = Undersize, chrome-plated

4 = Undersize, non-plated

5 = Oversize, chrome-plated

Do not change rotor sizes without consulting your local

Moyno Sales Office. These variations are used for certain

specialized pumping conditions only.

4-42. Drive Shafts shown have hard-chrome plating on the

packing wear area. If non-plated drive shafts are required,

select the standard part number and change the last digit to

next higher number; example: PE0261 to PE0262. If the

optional shaft sleeve is used, refer to Table 4-13 and 4-14 for

appropriate part numbers.

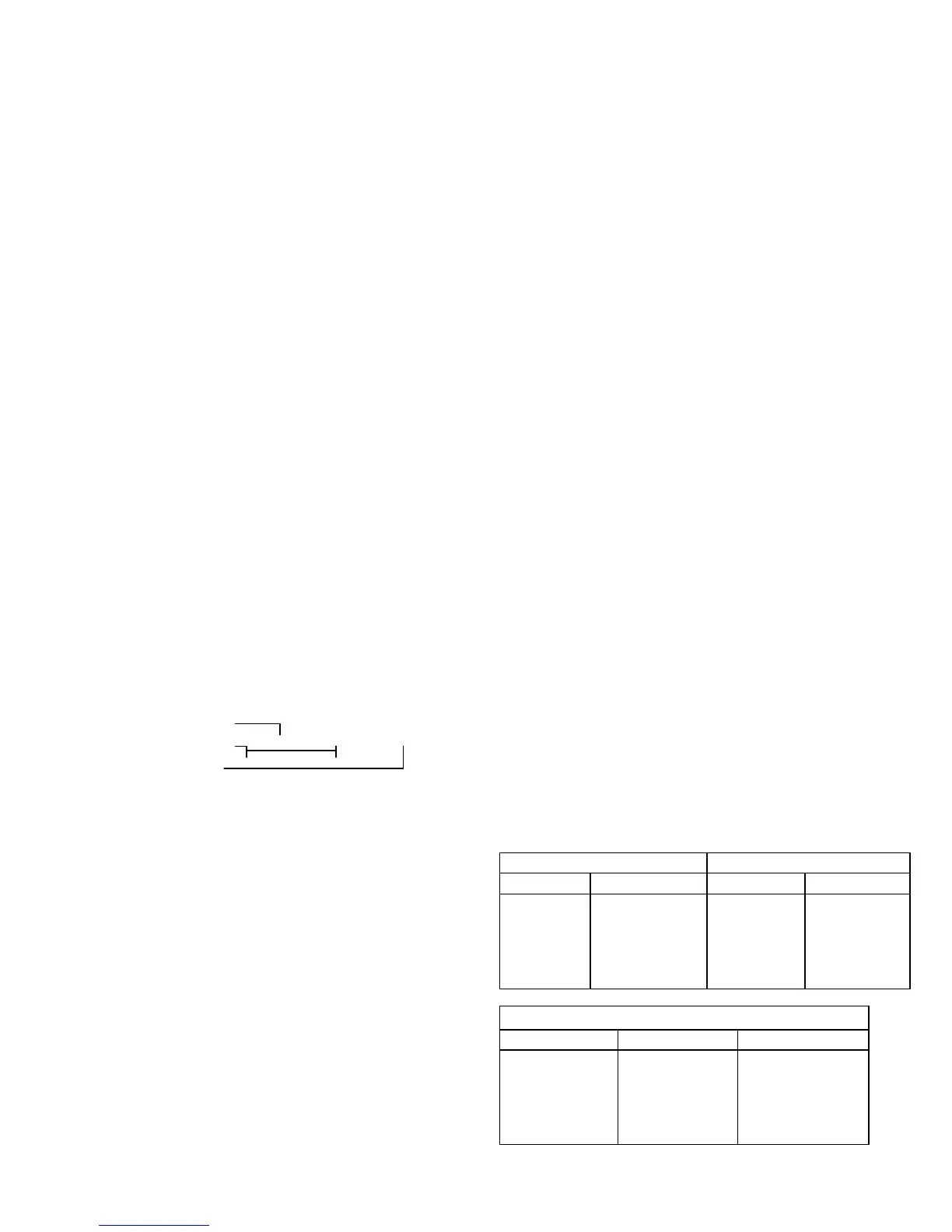

TORQUE GUIDELINES CHART

Stainless Steel Bolts Carbon Steel Bolts

Size Max. Torque Size Max. Torque

N0. 10-24

1/4-20

5/16-18

3/8-16

1/2-13

22.8 in. lb.

75.2 in. lb.

132 in. lb.

236 in. lb.

517 in. lb.

5/16-18

3/8-16

1/2-13

5/8-11

3/4-10

10 ft. lb.

21.7ft. lb.

43.5ft. lb.

86 ft. lb.

152 ft. lb.

Connecting Rod Lock Nuts

Drive End Nut Size Max. Torque

E

F

G,H

J

K

9/16-18

3/4-16

7/8-14

1 1/4-12

11/2-12

25ft.lb.

35 ft. lb.

50ft.Ib.

85 ft. lb.

110 ft. lb.

Note: Torque values are from the Industrial Fasteners In-

stitute and Craftsman Corp.

Loading...

Loading...