6. Wipe a small amount of grease in the groove of the

flush gland halves.

7. Work the split lip seal into the groove of one of the gland

halves.

8. Position the split such that it is away from the gland,

allowing the assembly to be placed around the drive shaft.

The lip of the seal should face away from the pump’s

bearings.

9. Work the lip seal into the groove of the remaining gland

half.

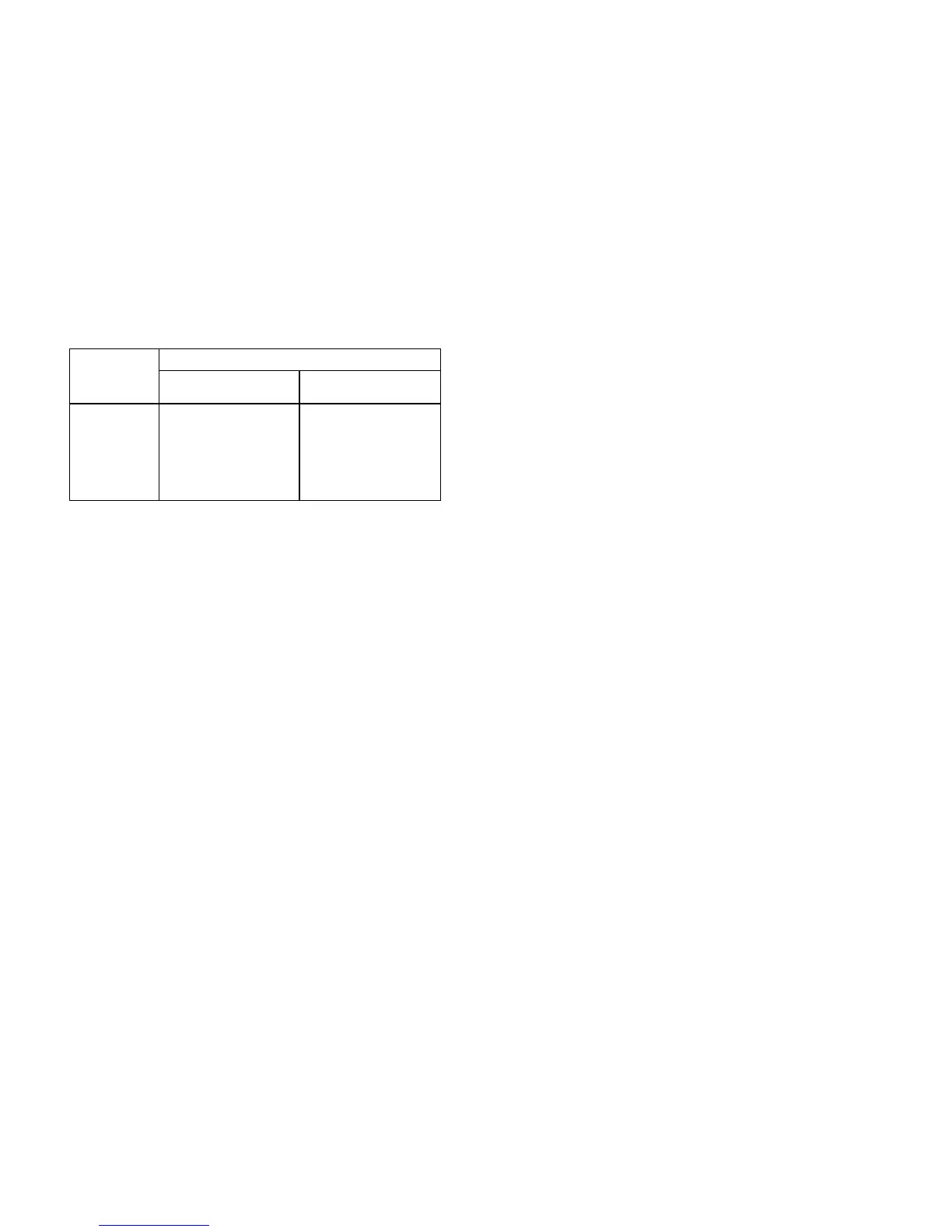

PACKING QUANTITY GUIDELINES

No. of Packing Rings

Drive End

Size

Without Lantern

Ring

With Lantern

Ring

E

F

G

H

J

K

8

9

7

7

7

7

6

6

6

6

6

6

10. With the seal in position and the gland halves held

together, install the two stainless steel cap screws.

11. Install the gland studs.

12. Slide the gland assembly onto the gland studs

finger tight.

13. Thread the appropriate hex bushing (depending on

flush gland inlet size) into the flush gland.

14. Thread the pressure regulator and pressure gauge

assembly into the hex bushing.

Note: The pressure regulator will reduce inlet water to below

8 psig, protecting the flush gland lip seal. Failure to

utilize the pressure regulator may result in premature

pump failure.

4-56. OPERATION

A flushable packing gland can be operated in one of

two ways:

• If the process fluid is relatively clean (non-abrasive) and

cannot be diluted by water flushing, allow it to leak along the

shaft, to provide both lubrication and heat dissipation. The

leakage will spill into the gland and be flushed to the drain.

No lantern rings are required, only the number of packing

rings listed in the above table. If the gland is operated this

way, pipe plugs should be installed in the 1/8-inch NPT holes

in the stuffing box.

• For applications involving abrasive fluids that can be

diluted somewhat with flush water, it is recommended that you

equip the stuffing box with lantern rings and install a water flush

line in the 1/8-inch NPT hole. Excess water spilling into the

gland can be plumbed to the drain. Install a pipe plug, instead

of a water supply line, in the flush gland inlet.

Page 27

Having determined the best alternative for your

application, install all hardware, leaving the flush gland drain

unconnected for now. Packing gland nuts should be evenly

adjusted so they are a little more than finger tight.

Overtightening the packing may result in premature packing

failure and possible damage to the drive shaft.

1. Start the pump and water flush the stuffing box if applic-

able (do not start the water flush in the gland at this point).

2. Adjust the gland nuts until you obtain a leakage rate of

1-2 drops per second. The flush gland drain must be discon-

nected to adjust the rate.

3. Allow the pump to run, checking the leakage rate every

15 minutes. If leakage becomes excessive, tighten the gland

nuts until the leakage amount is acceptable.

CAUTION: Do not tighten the gland nuts to the point of

zero leakage from the stuffing box.

4. Once the packing has seated and the leakage rate has

stabilized, the flush gland drain can be connected and flush

water can be run into the top side of the gland. Do not place

a throttling valve on the drain side of the flush gland. Do not

produce back pressure by any other way. Back pressure is

not necessary and is detrimental to the function of the gland.

5. Adjust flush water flow rate to an acceptable rate.

Loading...

Loading...