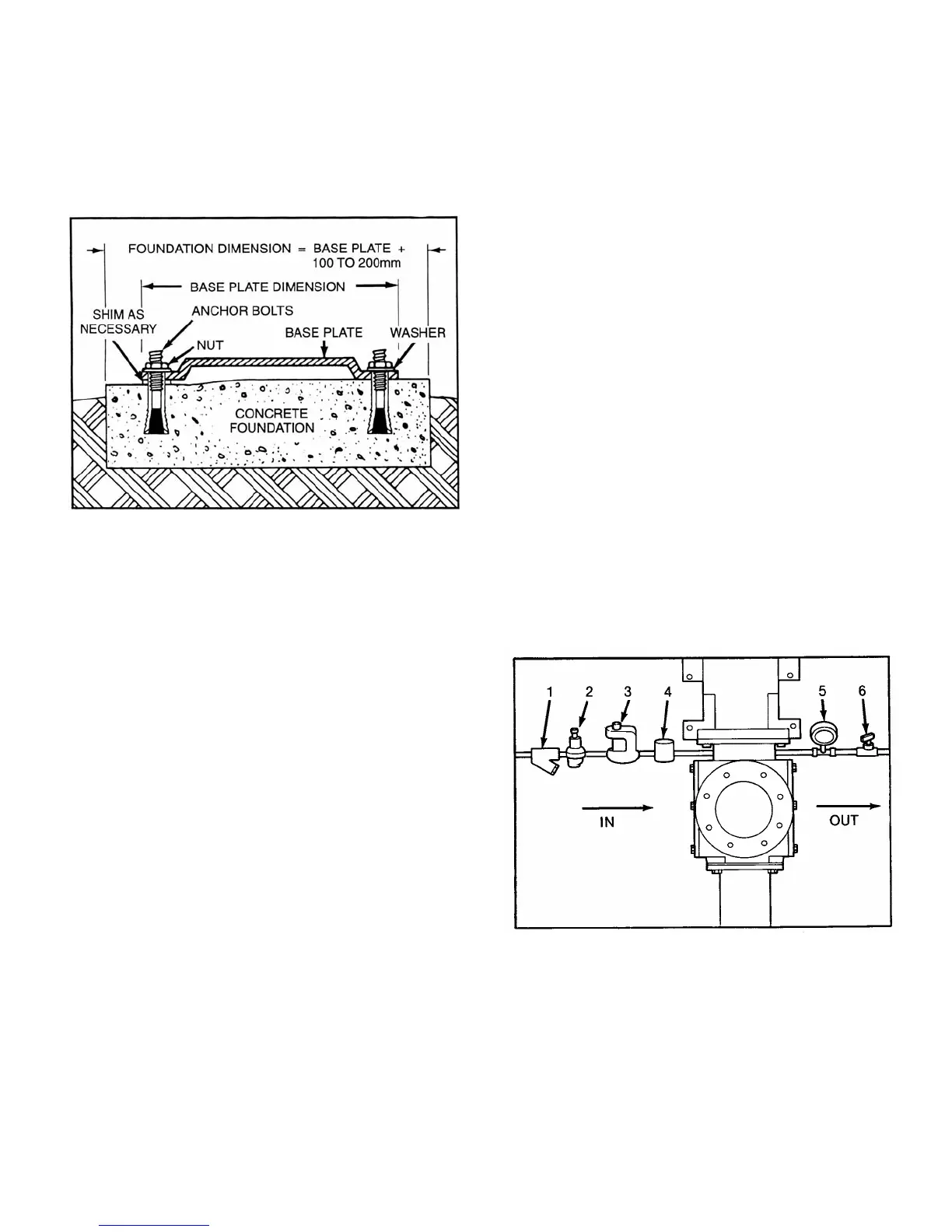

2-7. FOUNDATION

Each unit should be mounted on a strong, fabricated-steel

base plate. The base plate should be mounted on a concrete

foundation. The foundation should be approximately 4” to 8”

longer and wider than the base for which it is built. (See fig.

2-1.) Anchor bolts for the base plate should be located in the

foundation.

Figure 2-1. Typical Foundation Example

Check the base plate surface with a carpenter’s level and

place shims under the base plate at the places necessary to

make it level. Then check the pump, driver shaft and the

pump ports to ensure that they are level. Complete base

mounted units supplied by Moyno including pump and driver

are leveled with respect to the base at the factory. Shifting

may occur during shipment. The pump and driver should be

realigned. Care should be exercised to ensure that all

components are level and mounted in a direct line.

For maximum rigidity and lower noise levels the base

plate should be grouted to the foundation after the anchor

bolts have been evenly tightened. A good grade of non-

shrink grout is recommended. The spaces between the base

plate and the foundation around the shims should also be

filled with grout. Allow the grout to dry according to

manufacturer’s instructions, then fully tighten the anchor

bolts.

2-8. SHAFT ALIGNMENT

Although the base-mounted units supplied by Moyno are

leveled with respect to the base before shipment, most of the

larger pump and driver units are shipped with the flexible

coupling disconnected.

After the base has been bolted down to the foundation,

check the following conditions:

2-9. On coupling connected units, be sure that the pump

and driver shafts are realigned before the coupling is con-

nected. Care should be exercised to ensure that all com-

ponents are level and mounted in a direct line.

Page 3

Check gap between coupling halves (refer to coupling

manufacturers recommendations). Adjustment can usually

be accomplished by loosening the mounting bolts on either

the pump or driver and moving the loosened component into

alignment with the fixed component. On couplings with equal

diameter hubs, it may be possible to lay a straight edge

axially across the coupling halves to check alignment.

2-10. On belt drive units, check to ensure that sheaves or

sprockets are in alignment. Check belts for proper tension.

Tension requirements will vary with type of belt, center

distances, and belt speeds. Consult belt manufacturer for

specific recommendation.

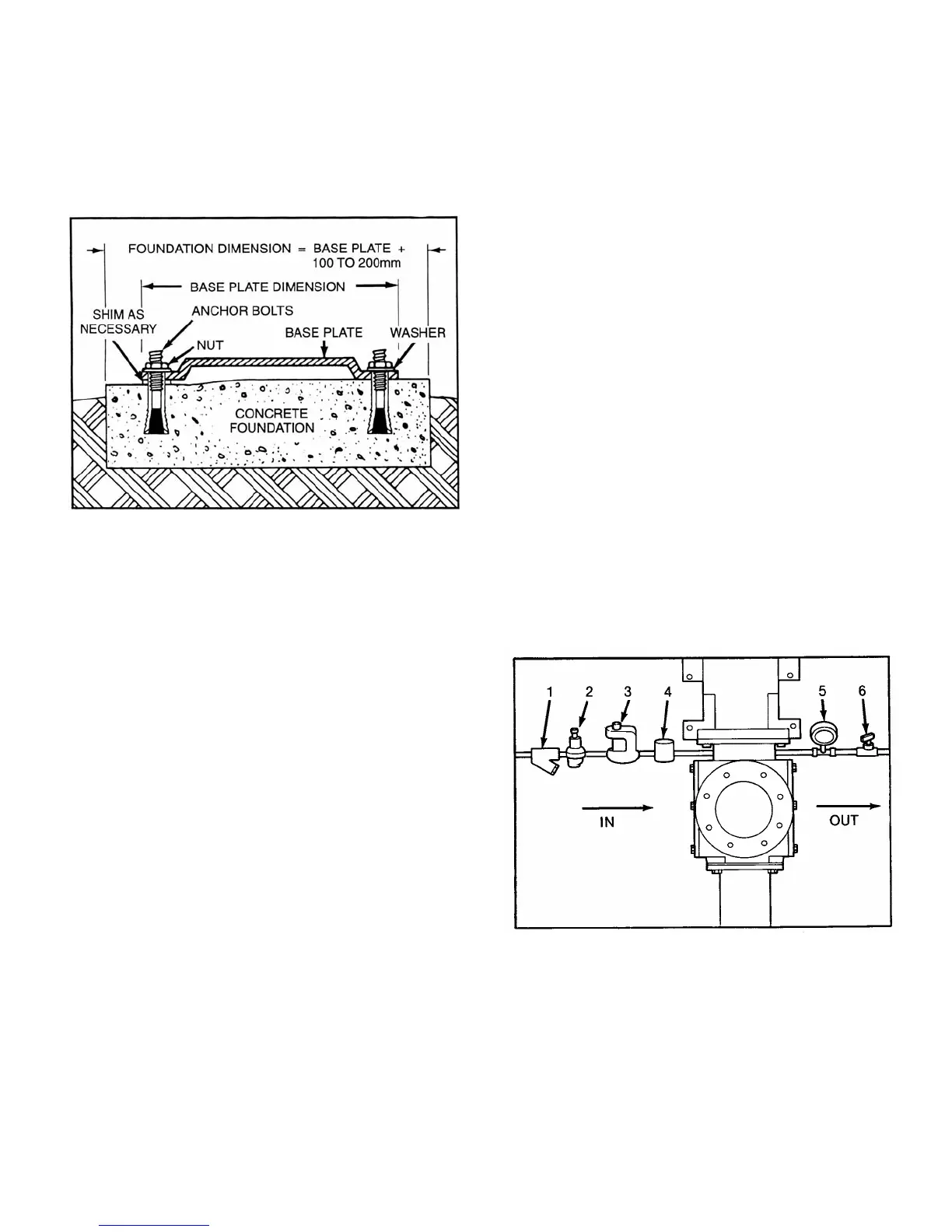

2-11. WATER FLUSH OF PACKING

The packing may be either grease lubricated through a

grease fitting in the stuffing box or have plumbing connected

to the housing to allow for water flushing.

Packing is not grease lubricated at the factory prior to

shipping.

When the material being pumped is abrasive, water

flushing the packing is recommended to extend shaft life.

Clean water can be injected though a 1/8” NPT hole that

normally houses the grease fitting for lubricating the packing.

The water should be permitted to leak axially along the shaft

and be removed from the second tapped hole in the stuffing

box. The discharge from the stuffing box should be throttled

slightly to maintain 10-15 PSI higher pressure in the stuffing

box than is present in the suction housing. (See fig. 2-2.)

Flow rate should be approximately 1/2-2 gpm.

If a mechanical seal is used, consult the seal manufac-

turers’ instructions for seal flush requirements.

Figure 2-2. Typical water flush arrangement for units

with packing includes strainer valve (1), pressure

regulating valve (2), sight flow meter (3), solenoid

valve (4), pressure gauge (5), and needle valve (6).

Loading...

Loading...