mr

.

steam

®

C U S E R I E S Installation, Operating & Maintenance Manual

13

American College of Sports Medicine Health/Fitness

Faculty Standards and Guidelines, or a similar resource

and reference publication, and refer to those guide lines

for the proper and safe operation of a spa facility includ-

ing steam rooms. Steam room construction information is

avail-able from the Tile Council of America, Inc. at (864)

646-8453 or www.tileusa.com.

The Digital 1

®

Temperature Control System

is required operating equipment for each steam room.

The operating temperature control is to be set by the

owner/operator to sense desired room temperature at

the sensor location within the steam room. Connection of

the Over Temperature portion of the Digital 1 control is

mandatory to provide additional protection to the

bathers. The steam room is to be operated in accor-

dance with “Important” information as noted above.

IMPORTANT:

Final selection of the steam room temperature setting is

at the discretion of the owner/operator.

Ensure all splices in the sensor cable are

securely crimped soldered and sealed with heat

shrink tubing.

CONTROL CIRCUIT WIRING DIAGRAM

SEE PAGES 11, 12 & 13 FOR DIAGRAMS

Installer shall use a safety switch of ade-

quate capacity employing suitably rated circuit breakers

or fuses between main electrical power source(s) and the

generator. Location of safety switch to be in accordance

with National and local electrical codes.

NOTES:

1. Larger rooms may require two or more steam solenoid

valves in parallel.

2. When generator services two rooms, second room

requires a set of Digital 1

®

and solenoid valves.

IMPORTANT:

3. Digital 1

®

sensors are intended to be field installed

within the steam room at the location selected by the

designer/architect. DO NOT LOCATE THE Digital 1

SENSOR NEAR OR ABOVE THE STEAMHEAD(S) AS

THIS MAY CAUSE DIRECT STEAM EMISSION TO

INTERFERE WITH STEAMROOM TEMPERATURE REG-

ULATION.

4. Autoflush System 24 hr. timer and Digital 1

®

operating

settings are at the discretion of the owner/operator.

IMPORTANT: Owners/operators should obtain a copy

and familiarize themselves with the latest edition of the

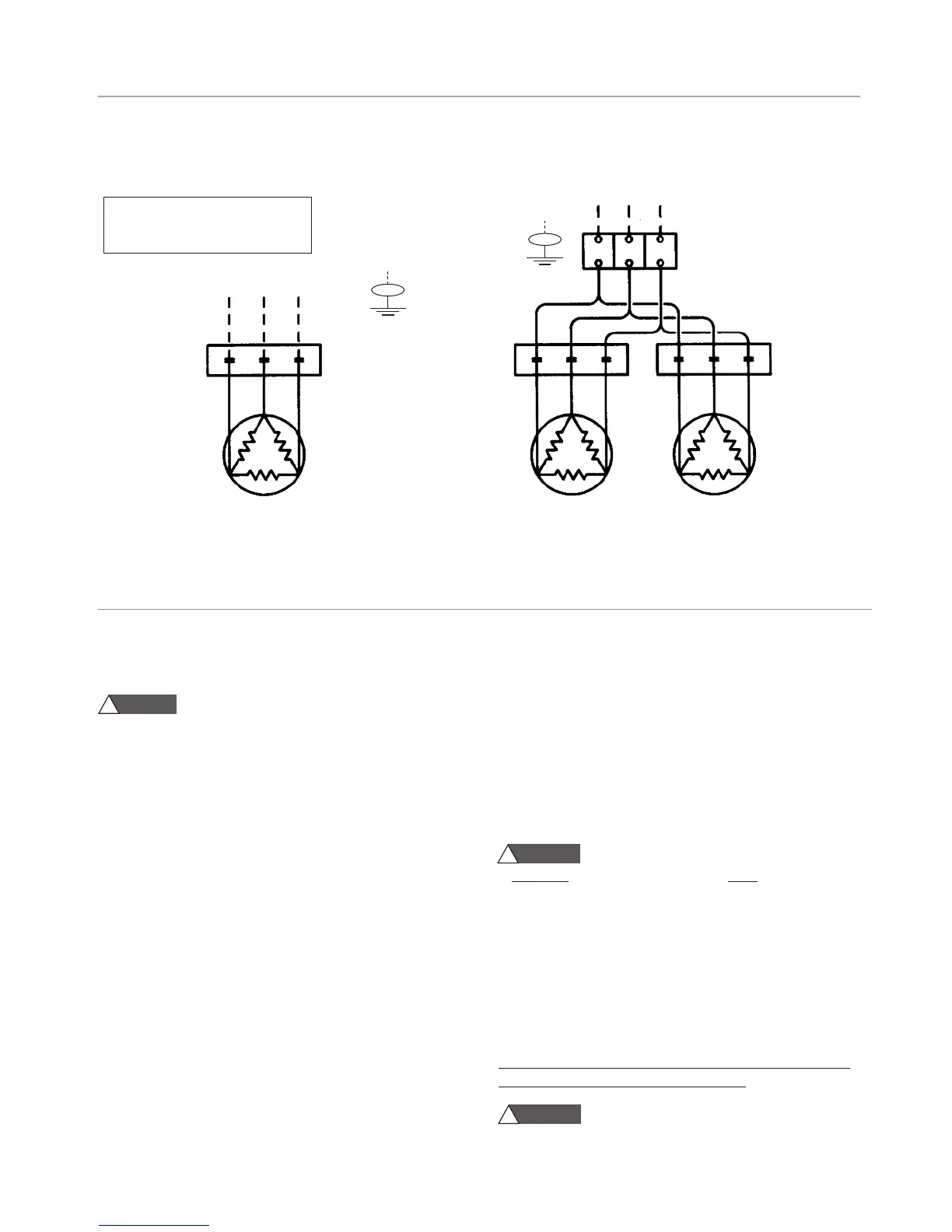

3PH Power Supply

Power Contactor

Heating Element

Diagram #1

Units with 1 Contactor (see note 1)

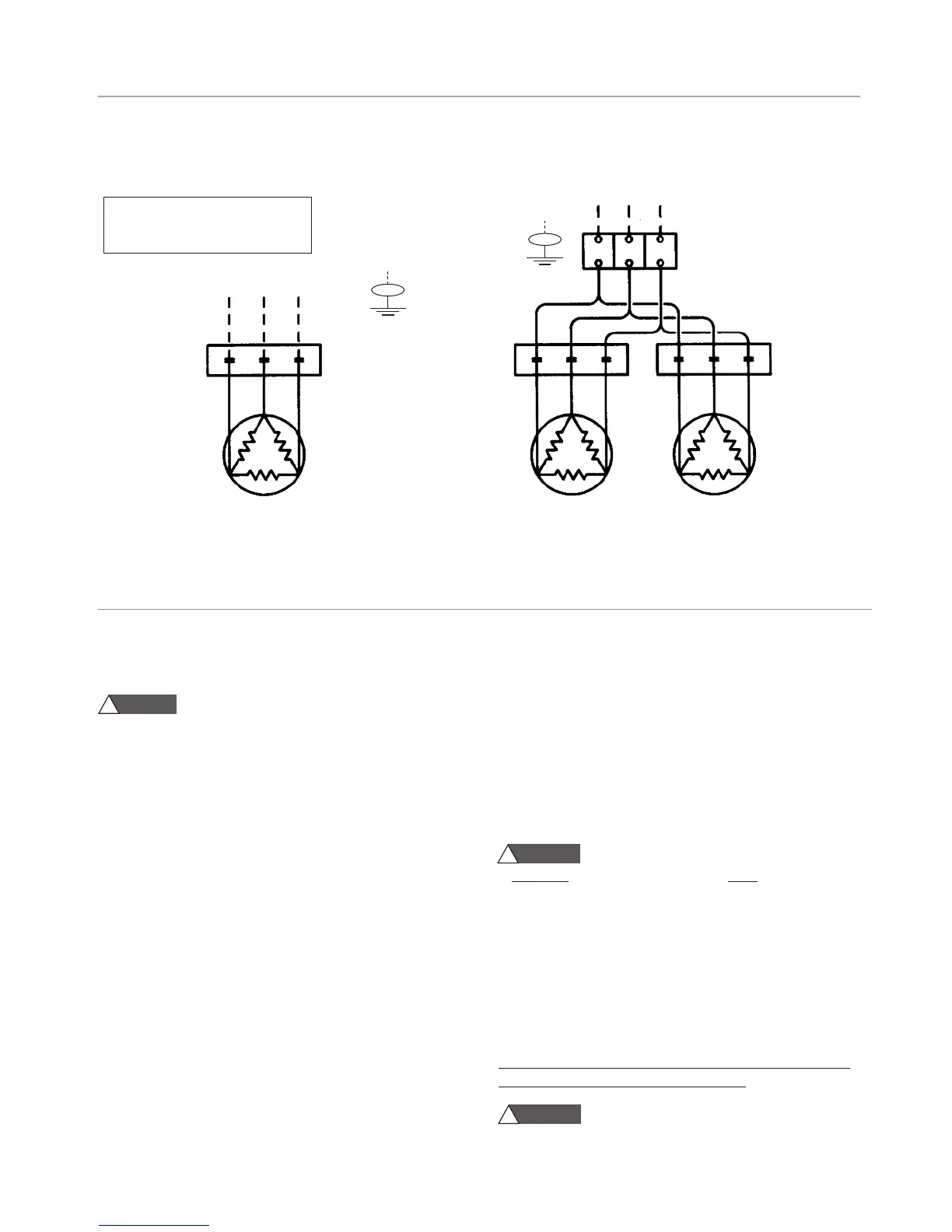

3PH Power Supply

Power Terminal Block

Power Contactors

Heating Elements

Diagram #2

Units with 2 or more Contactors (see note 1)

GRD

GRD

__ __ __ __

Field Wiring

__________

Factory Wiring

IMPORTANT:

Also refer to Control Circuit diagrams in this manual.

TYPICAL POWER WIRING DIAGRAM

WARNING

!

WARNING

!

CAUTION

!

Loading...

Loading...