mr

.

steam

®

C U S E R I E S Installation, Operating & Maintenance Manual

23

PRESSURE CONTROLS OPERATION

AND TESTING

Steambath generators are provided with one hi-limit pressure control

and at least one operating pressure control.

1. All pressure controls are equipped with a screw allowing for setting

of the desired operational and hi-limit pressures.

2. It is recommended that the hi-limit control be set at 8–10 psig maxi-

mum and the operating pressure control(s) shall not be set above 5

psig.

NOTE: Models CU360 - CU3000 are provided with one (1) automatic

reset operating pressure control and one (1) manual reset high limit

pressure control. Models CU 4500 is provided with two (2) automatic

reset operating pressure controls and one (1) manual reset high limit

pressure control.

3. Pressure control operation check: Manually close the steam

outlet valve. Switch the generator on to allow for steam pressure

build-up. Pressure gauge reading will build and the operating pres-

sure control will shut off the generator at the pressure setting. Re-

setting the operating pressure control is accomplished by manually

bleeding off pressure through the steam outlet valve and allowing

the pressure to drop below the desired set point.

TORQUE VALVES

Check to insure all element flange bolts, element terminals, and con-

tactor terminals are tightened to the following specifications.

IMPORTANT:

See page 29 for

additional information

and illustrations.

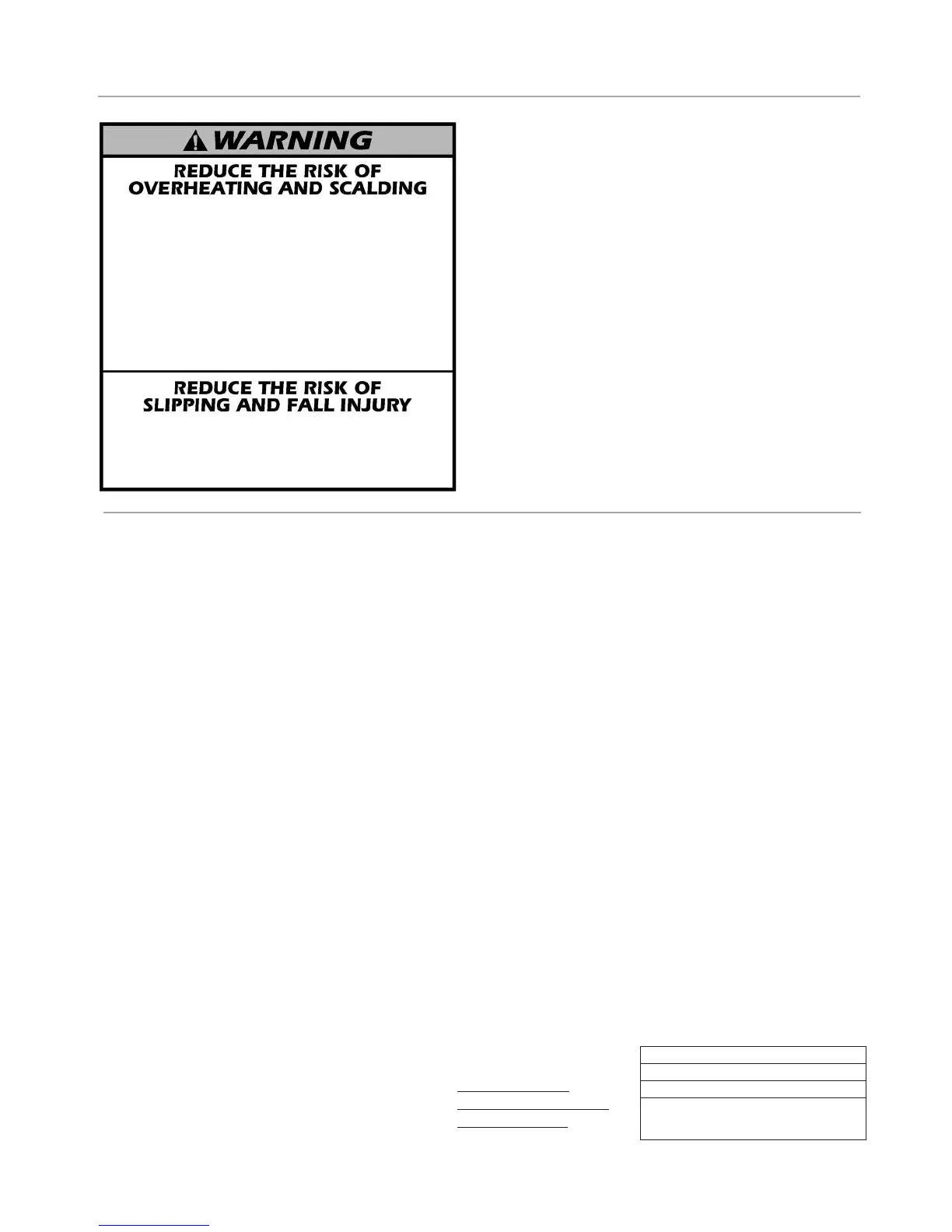

WARNING SIGNAGE

T

he CU Steambath generator is provided with a

WARNING sign. This WARNING is to be secured

to the outside of the steam room, on the steam-

room door or adjacent to that door. It's location

must be such that all steam bathers are readily

made aware of the important information con-

tained in the sign.

TORQUE VALUES

Element Flange Bolts 22 lb-ft

Element Terminals 20 lb-in

Contactor Terminals : Tighten to

torque specified on contactor.

1

. Exit immediately if uncomfortable, dizzy or sleepy. Staying too long in a heated

a

rea is capable of causing overheating. Limit yourself to a maximum of ten

(

10) minutes. High temperature and humidity can be dangerous to your health.

2. Children under the age of 16 should not use this facility.

3

. Check with a doctor before use if pregnant, diabetic, in poor health or under

m

edical care.

4. Breathing heated air in conjunction with consumption of alcohol, drugs

or medication is capable of causing unconsciousness. Therefore, do not use

this facility if you have recently consumed alcohol, drugs or medications.

5

. Do not contact steam head or steam at the steam head.

6. Allow yourself at least five (5) minutes after exercising to cool down before

entering this facility.

U

se care when entering or exiting the steam room. Floors may be slippery and

dangerous due to moisture. Use of proper footwear is recommended at all times.

Note: For additional safety considerations see Owners manual.

mr

.

steam

®

4

3-20 34th Street, Long Island City, NY 11101 1-800-76-STEAM www.

m

rsteam.com

PRE-OPERATION CHECK

Low water Cutoff (LWCO) and

Feed Control Operation and Testing

1. All valves for incoming water supply are to be fully

opened. Main disconnect switch to be in "ON" posi-

tion. Generator switch to be in “ON" position. Since

generator will be empty, water solenoid will be ener-

gized allowing the generator to fill with water until

proper level is reached. Then the contactors will ener-

gize and supply voltage to heating elements.

2. Water level control operation: At this point the water

should be visible approximately half way up the sight

glass. Slowly open the drain valve located at bottom

of the generator. The water level will fall allowing the

low water cutoff/water level control to energize the

feed water system. Close the drain valve for proper

operation.

3. Low water cut-out switch performance. Close water

feed valve. Open the drain valve completely. Maintain

this condition until the water level falls within the

gauge glass enough to cause the low water cutout

switch to de-energize the heating elements. All con-

tactors will be in the de-energized state at this time.

Close the drain valve. For automatic re-setting type

low water cutoff switches, feed system will return the

water level to normal. For manual re-set the reset but-

ton must be depressed to complete circuit. The gen-

erator is now qualified for proper low water cutout

and normal liquid-level operating conditions.

NOTE: For automatic blowdown, turn timer off and on

until water level is low enough to de-energize heaters.

Loading...

Loading...