24

Temposonics

®

ET Analog ATEX / IECEx / CEC / NEC / CCC Certified

Operation Manual

6. Maintenance and troubleshooting

6.1 Error conditions, troubleshooting

6.2 Maintenance

The required inspections need to be performed by qualified personnel

according to IEC 60079-17 / TRBS 1203. These inspections should

include at least a visual inspection of the housing, associated electrical

equipment entrance points, retention hardware and equipment

grounding. Inside the Ex-atmosphere the equipment has to be cleaned

regularly. The user determines the intervals for checking according to

the environmental conditions present at the place of operation. After

maintenance and repair all protective devices removed for this purpose

must be refitted.

In case of equipment faults, remove the equipment. The inner

parts cannot be maintained by the customer. In this case send the

equipment to the manufacturer for inspection.

Maintenance: Defines a combination of any actions carried out to

retain an item in, or restore it to, conditions in which it is able to meet

the requirements of the relevant specification and perform its required

functions.

Inspection: Defines an activity with the purpose to check a product

carefully, aiming at a reliable statement on the condition of the

product. The inspection is carried out without dismantling, or, if

necessary, with partial dismantling, and supplemented by other

measures, e.g. measurements.

Visual inspection: Optical inspection of product aims at the recognition

of visible defects like missing bolts without using auxiliary equipment

and tools.

Close inspection: Defines an inspection which encompasses those

aspects covered by a visual inspection and, in addition, identifies those

defects, such as loose bolts, which will be apparent only by the use of

access equipment, for example steps, where necessary, and tools.

6.3 Repair

Repairs on the sensor may be performed only by MTS Sensors or an

explicitly authorized body.

6.4 List of spare parts

No spare parts are available for this sensor.

6.5 Transport and storage

The conditions of transport and storage of the sensor match the

operating conditions mentioned in this document.

7. Removal from service / dismantling

The product contains electronic components and must be disposed of

in accordance with the local regulations.

NOTICE

It is not allowed to open the sensor.

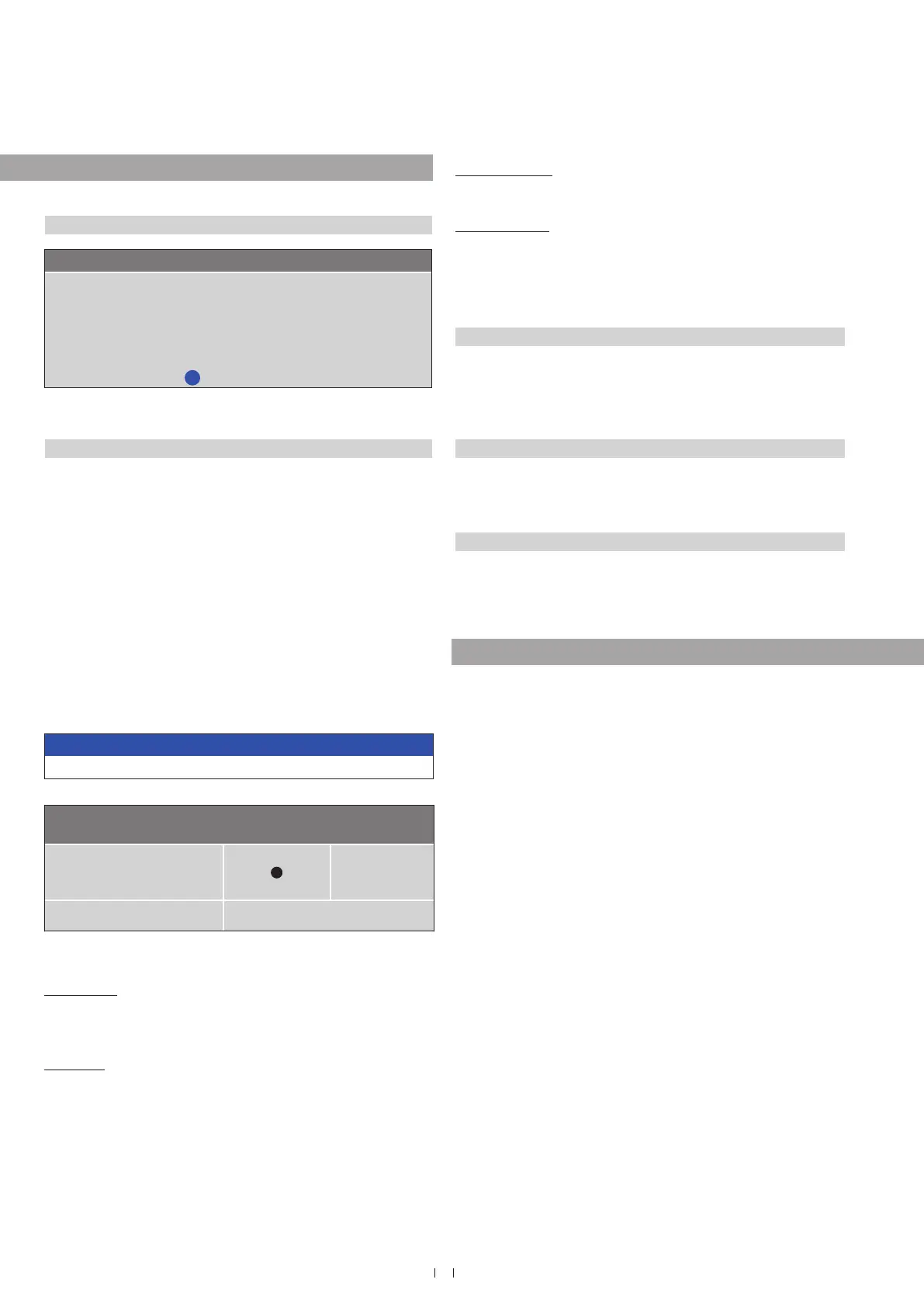

Fig. 39: Troubleshooting

Error condition Status

Magnet error Default error value at output:

Voltage output: 10.35 V

Current output: 20.3 mA

Adapted error value at output:

−0.7…20.3 mA or −0.4…10.4 VDC

(see

12

on page 22)

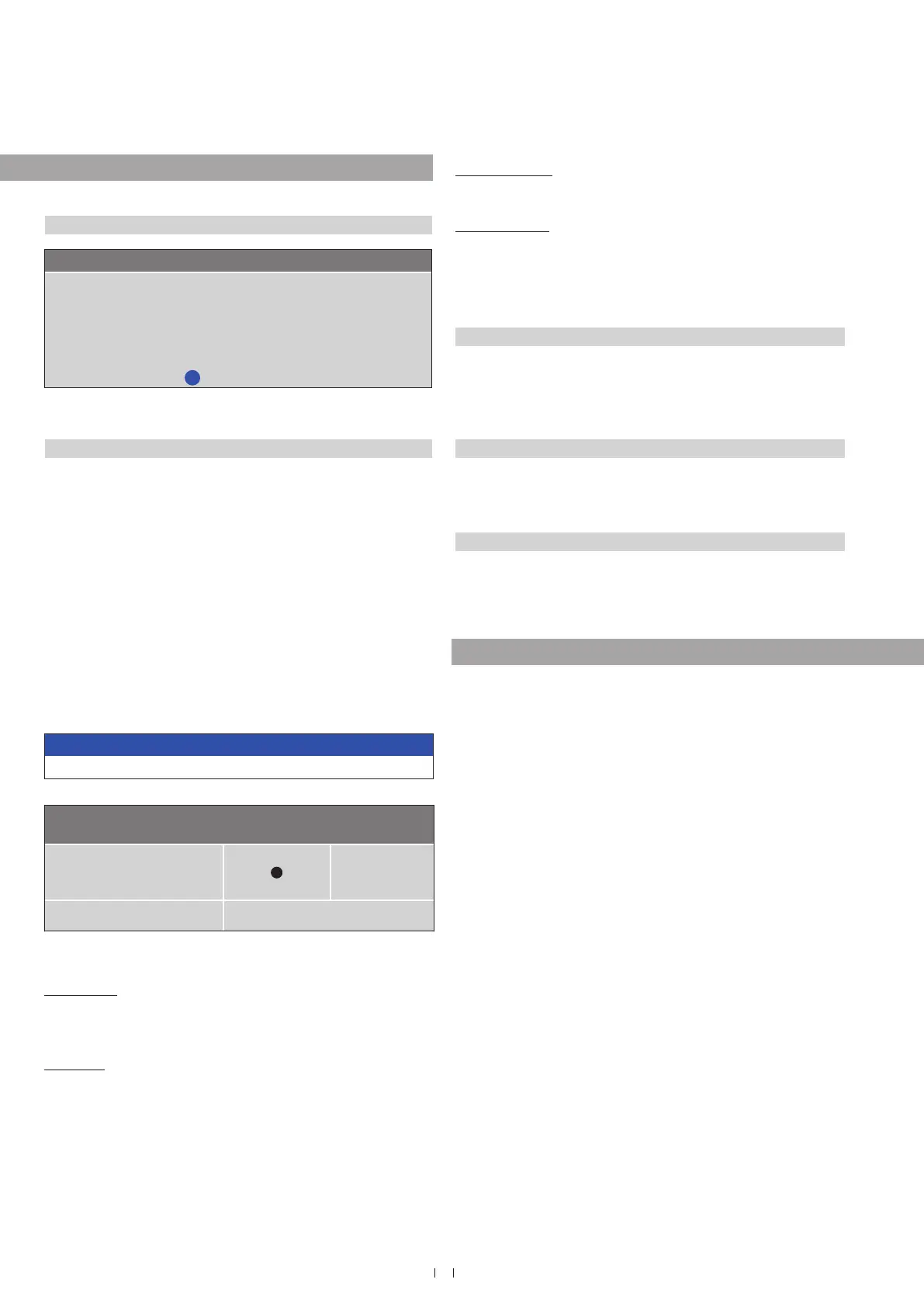

Type of inspection Visual inspection

every 3 months

Close inspection

every 6 months

Visual inspection of the

sensor for intactness, removal

of dust deposits

Check of entire system User‘s responsibility

Fig. 40: Schedule of inspection

Loading...

Loading...