20

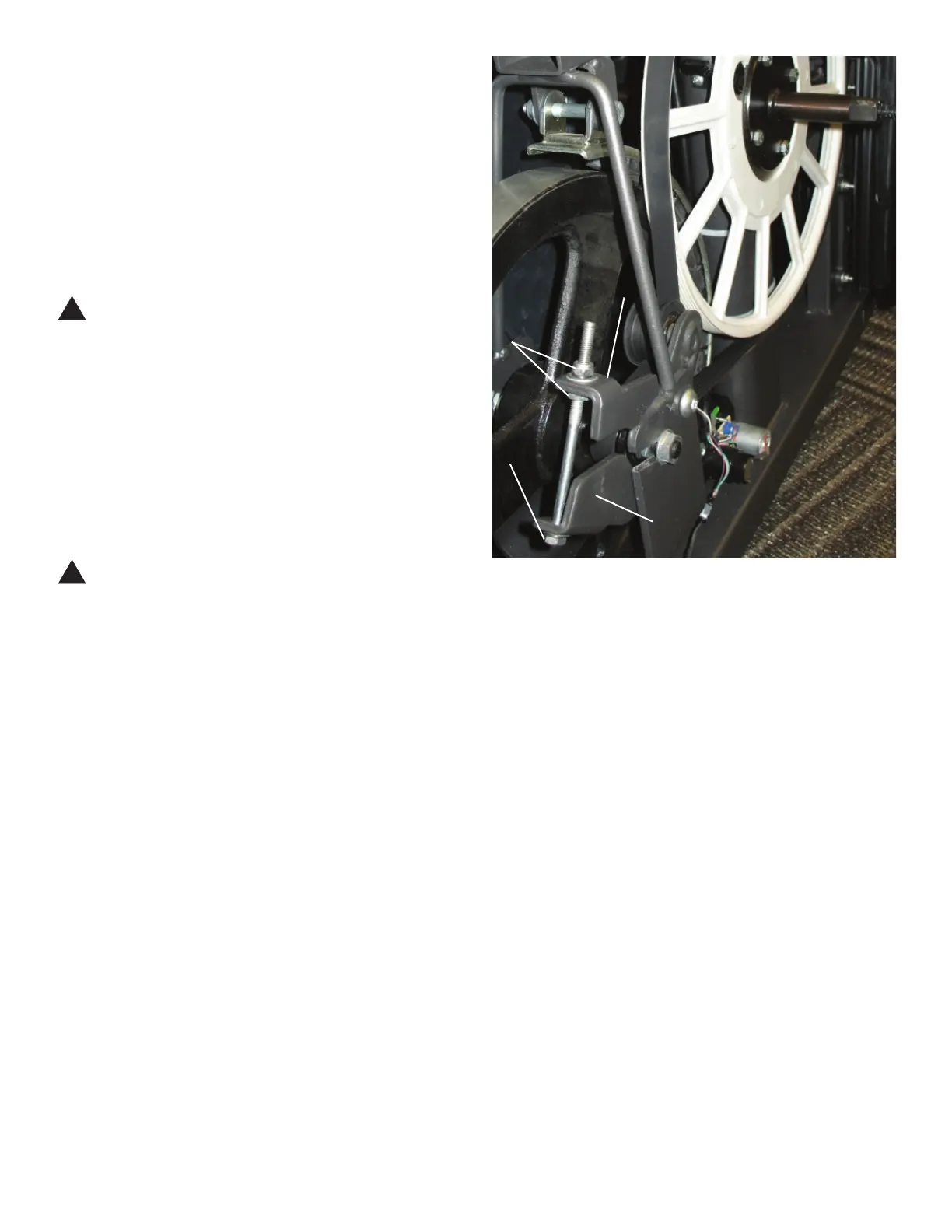

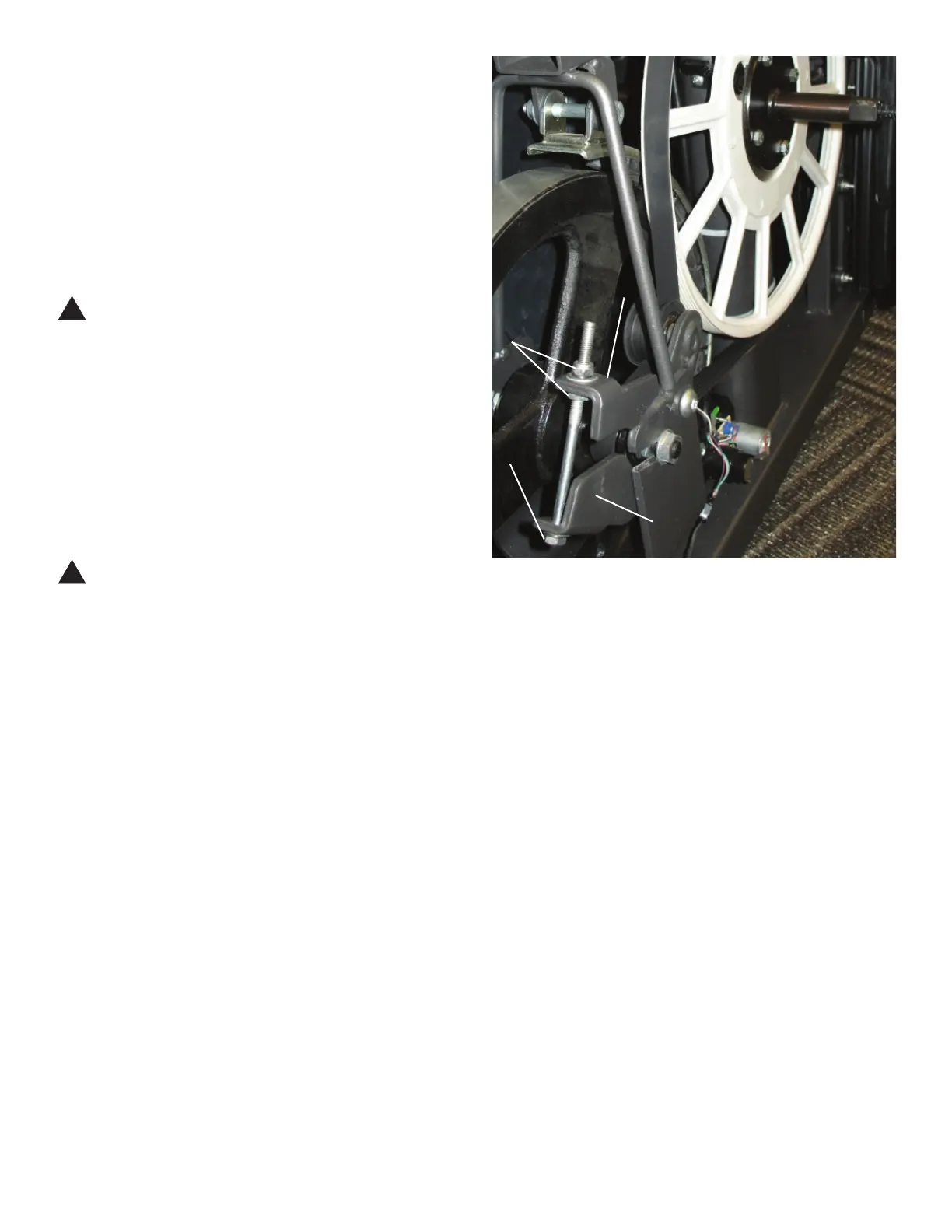

3. To adjust the nuts (C) on the Tensioner Assembly (A), use a 10mm

open end wrench to hold the bolt (B) steady and turn the nuts with a

second 10mm open end wrench.

4. When the tension is correct, tighten the nuts (C) against the

7HQVLRQHU%UDFNHW'WRKROGWKHEROW%DQGWKH7HQVLRQHU

Assembly (A) in position.

Note: This step may require two people.

5. Carefully turn the crank arm and check the movement of the drive

belt. The Crank Arms and Flywheel should move as one.

!

%HVXUHWRNHHSÀQJHUVFOHDURIDOOSLQFKKD]DUGVZKHQ\RX

turn the Drive Pulley.

Adjust the belt tension again if necessary.

6. Reassembly is the reverse procedure.

NOTICE: Be sure not to crimp any cables.

7. Final Inspection

Inspect your machine to ensure that all hardware is tight and components

are properly assembled.

!

Do not use until the machine has been fully assembled and

inspected for correct performance in accordance with the

Owner’s Manual.

A

C

B

D

Loading...

Loading...