© by N&W GLOBAL VENDING S.p.A. 45 10 2009 3325 - 00

Chapter 3

Maintenance

The intactness of the machine and its compliance

with the rules of the relative installations shall be

checked by skilled personnel at least once a year.

Never forget to power o the machine before

performing any maintenance operation that may

require the disassembly of components.

The operations described here below may be only

performed by the personnel who have a specic

knowledge of the machine operation from the view-

point of electric safety and health rules.

GENERAL INTRODUCTION

To ensure the correct operation all over the time, the

equipment must be serviced at regular intervals.

All necessary operations and the relative deadlines are

listed here below. Obviously, they are merely indicative

since they depend upon operating conditions (e.g. water

hardness, humidity and room temperature, type of prod-

uct in use, etc.).

The operations described by this chapter are not intend-

ed to exhaust all maintenance operations.

The most complex operations (e.g. boiler descaling)

must be carried out by a technician having a specic

knowledge of the vending machine.

In order to avoid any risk of oxidation or chemical cor-

rosion in general, keep stainless steel surfaces well

cleaned and painted by using neutral detergents (please

avoid any solvent).

Under no circumstance is it allowed to use water

jets in order to wash the machine.

BREWING UNIT MAINTENANCE

The coee unit must be serviced, even if slightly, every

10,000 dispensing cycles or, any way, every 6 months to

optimise its operation all over the time.

To provide for maintenance, remove the unit and act as

follows:

- Detach the coffee outlet nozzle (2) from the unit by

rotating it by 90° with respect to the connecting rod (4)

and by pulling it to the outside.

- Operate the lever (8) intended to lock the unit by rotat-

ing it to reach the horizontal position.

- Extract the coffee unit.

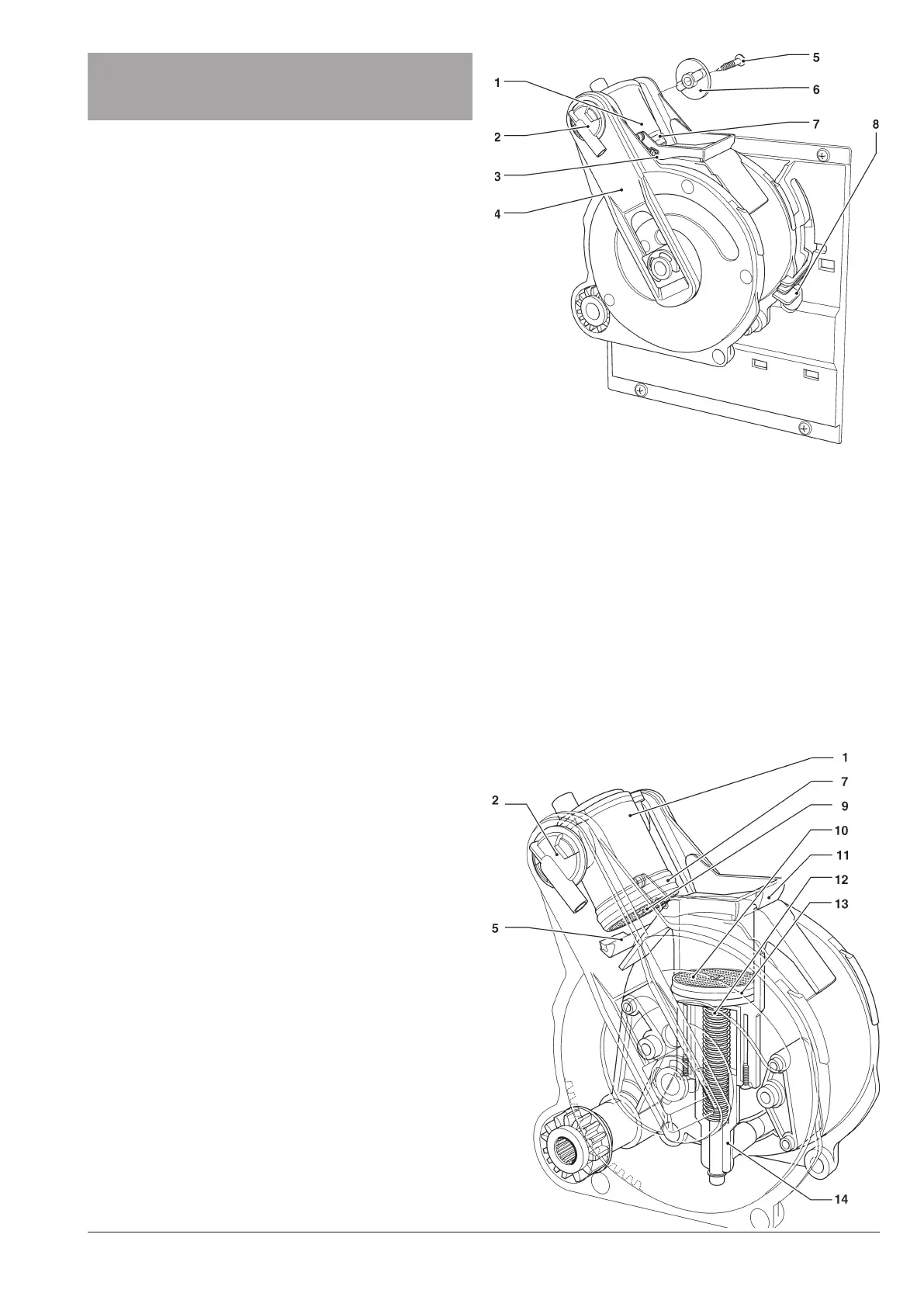

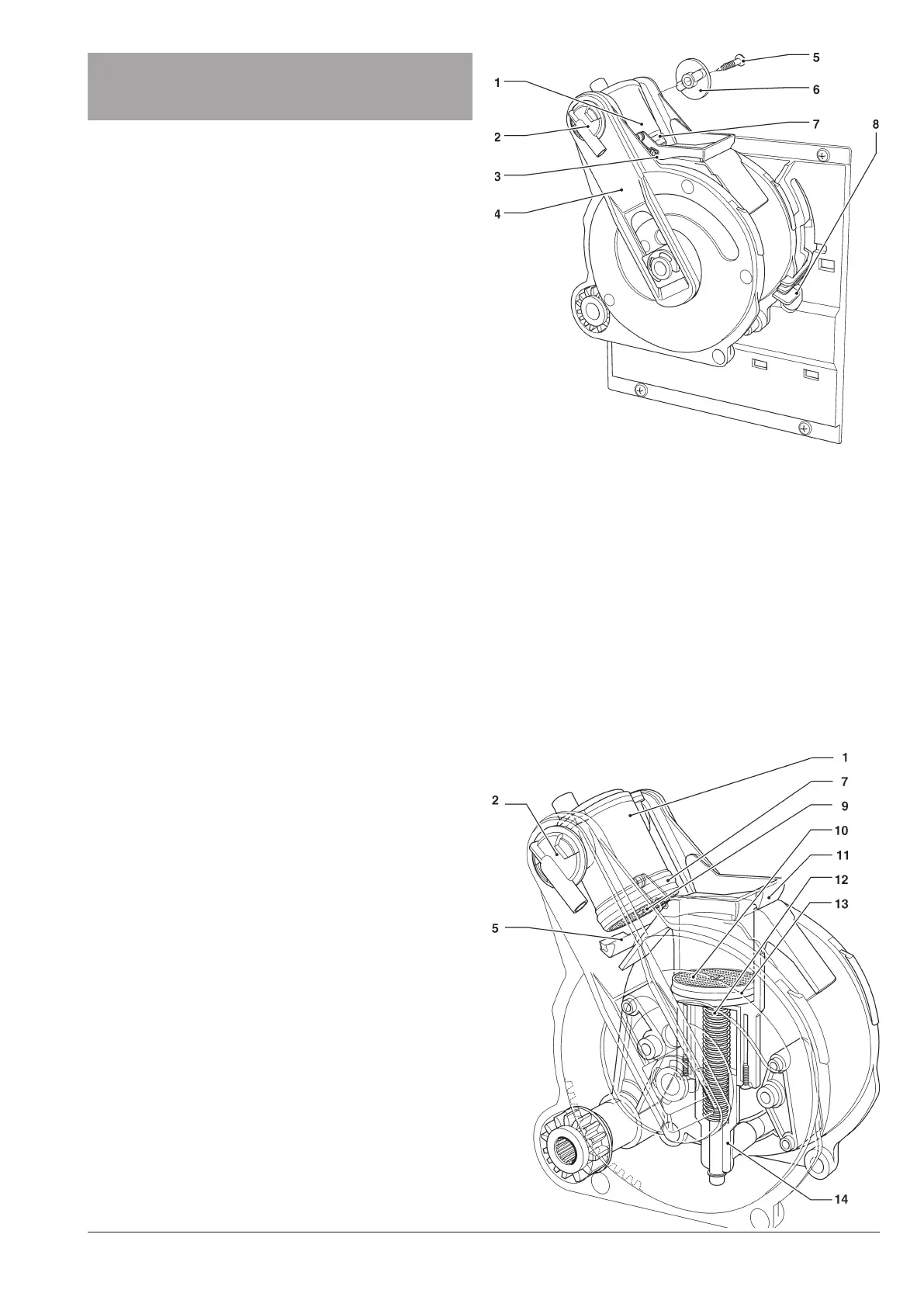

Fig. 30

1- Upper piston

2- Coffee outlet nozzle

3- Lower scraper

4- Connecting rod

5- Side screw

6- Key

7- Upper gasket

8- Unit locking lever

9- Upper filter

10- Lower filter

11- Lower scraper

12- Lower piston

13- Lower gasket

14- Piston rod guide

15- Upper scraper

Loading...

Loading...