© by N&W GLOBAL VENDING S.p.A. 46 10 2009 3325 - 00

Disassembling / replacing the upper lter and gas-

ket

To disassemble or replace the upper lter and gasket,

act as follows:

- Unscrew the side screw (6) intended to fasten the key

(5) of the upper piston.

- Rotate the upper piston (1) upwards.

- Remove and replace the upper gasket (7).

- Unscrew the upper filter (9) to remove and replace it.

Disassembling / replacing the lower lter and gas-

ket

To disassemble or replace the lower lter and gasket, act

as follows:

- Manually bring the unit into the unload position with the

lower piston (12).

- Unscrew the central fastening screw to remove the filter

(10).

- Press on the end of the piston rod guide (14) to get an

extra-travel of the lower piston (12).

- Use a small screwdriver to extract the lower piston (12)

from the piston rod (14). Pay special attention to avoid

damaging the piston or the sealing elements.

- Remove and replace the lower gasket (13).

PERIODICAL OPERATIONS

Clean and disinfect the whole circuit and the parts in

contact with the foodstus at least every year or more

frequently, according to the utilisation of the machine or

the inlet water quality.

SANITISING

- remove all the components in contact with the food-

stuffs, including tubes, from the machine and disas-

semble them in all their parts;

- remove all visible residues and films mechanically by

using pigs and scrapers, if necessary;

- the components shall be immersed into a sanitising

solution for at least 20 minutes;

- the internal surfaces of the equipment shall be cleaned

by using the same sanitising solution;

- rinse abundantly and reassemble the various parts.

Before setting the machine at work once again,

sanitise the machine after having assembled all the

components, as it is described by chapter “Sanitis-

ing mixers and food circuits”

channels and mixers

At regular intervals, it is necessary not only to remove

any powder residue from the parts outside mixing units,

in particular in the funnel area, but also to sanitise the

parts in contact with the mixer drink.

It is absolutely forbidden to use water jets for

cleaning.

The parts to be cleaned are listed here below:

- powder funnels, mixers and the conduit intended to

dispense instant drinks;

- dispensing tubes and nozzles;

- dispensing compartment.

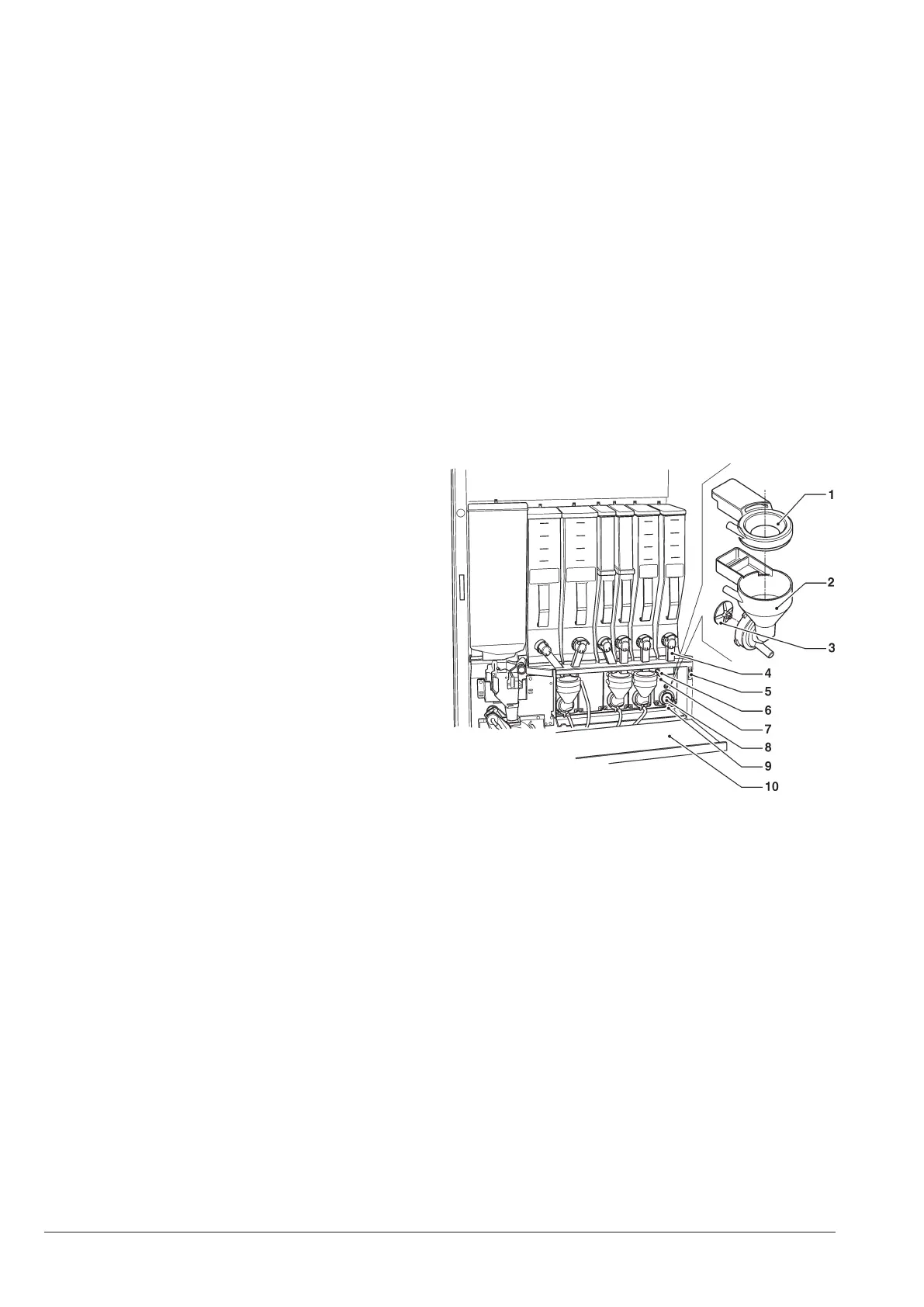

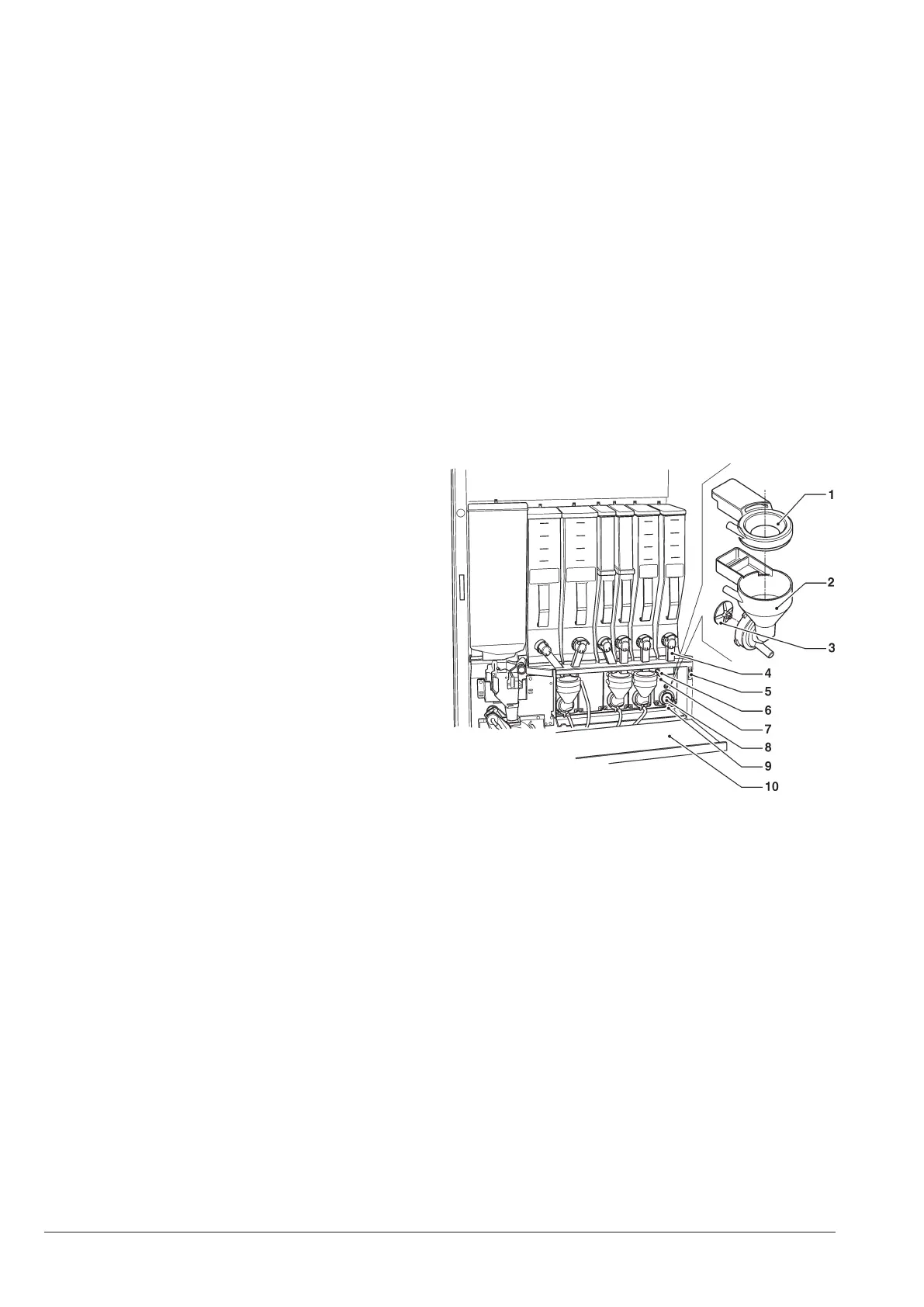

- Open the cover of the mixer dispensing box and lift the

powder outlet ports as far as the locking hook;

- remove the powder funnels, the water collection boxes,

the powder deposit funnels and the impellers of whip-

per motors from the mixers (see fig. 31);

Fig. 31

1- Powder funnel

2- Powder conveyor

3- Whipper impeller

4- Powder outlet port

5- Compartment closing magnet

6- Upper water inlet nozzle

7- Lower water inlet nozzle

8- Stuffing gasket

9- Mixer fastening flange

10- Dispensing box cover

Loading...

Loading...