Sensor

The Neutronics ZR-400E mini-zirconia percent range oxygen sensor (Figure 3) is a cost effective solution

for many applications. It is a solid-state device based on a zirconia solid electrolyte sensor with a low

power, on-board heater, and two electrodes. Unlike many solid-state oxygen sensors, the ZR-400E does

not require a reference gas for normal operation.

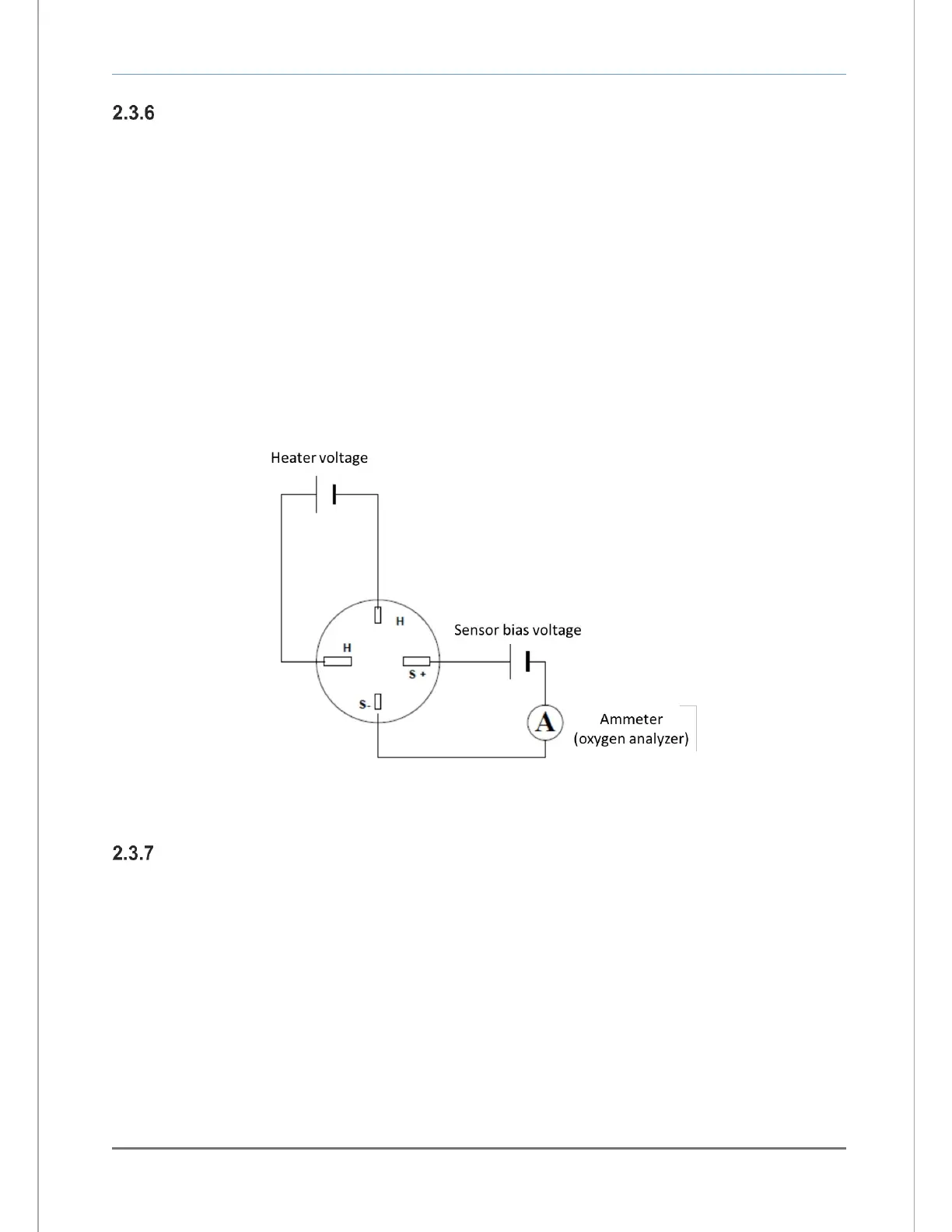

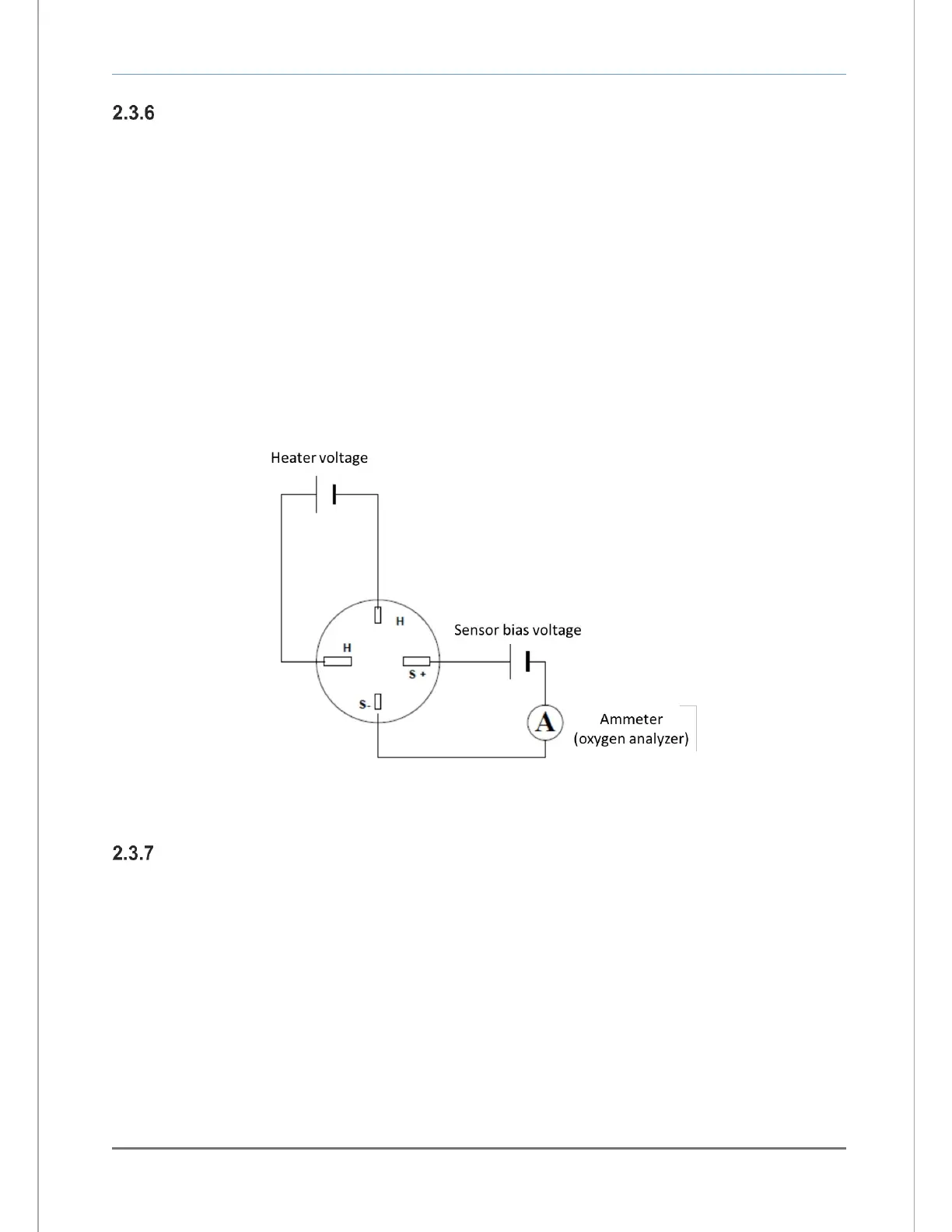

The sensor is mounted directly onto a printed circuit board that supplies bias and heater voltages to the

sensor element. A small capillary on the sensor surface controls diffusion of oxygen into the sensor. At

operational temperature, oxygen is electrochemically reduced, causing current flow through the solid

electrolyte. Oxygen concentration in the sample gas is determined by measuring the current flowing

through the sensor’s two electrodes.

The robust design of the ZR-400E sensor assures accurate measurement as well as a quick response

characteristic to serve a wide range of oxygen measurement applications. Operating service life is 3-5

years under normal operating conditions, and it has an unlimited shelf life. It is not affected by position

and may be exposed to several G-forces with no ill effect on performance.

Sensor flow-through head

The optional sensor mounting-base (Figure 4) allows the Model ZR-400E sensor to be used for process

monitoring. It serves as both the receptacle for the sensor and the delivery system for a gas sample from

a process vessel or stream. It includes a sample inlet, a flow-through chamber, a sample exhaust, and a

threaded connection for the oxygen sensor.

2.3.7.1 Sample gas inlet

Gas must be directed from the measured process to the sample inlet port via positive pressure from the

source or from an external pump. The Model ZR-400E sensor and flow-through head combination is

suitable for installation in any Neutronics Inc. Process Sampling System.

Loading...

Loading...