3.1.2.2 Sample inlet port

Pneumatic connection to the measured process for sample extraction is made at either of the two

interchangeable 1/8” FNPT fittings around the side of the flow-through head. For connecting the flow-

through head to the measured process, use 1/8" or 1/4" rigid tubing, and 1/8" MNPT fittings of a material

compatible with process gas composition. Ensure that no grease, particulate, or solvent is present in the

tubing during installation. Use thread-tape to seal connections, and prevent galling. Fix all sample tubing

and connectors.

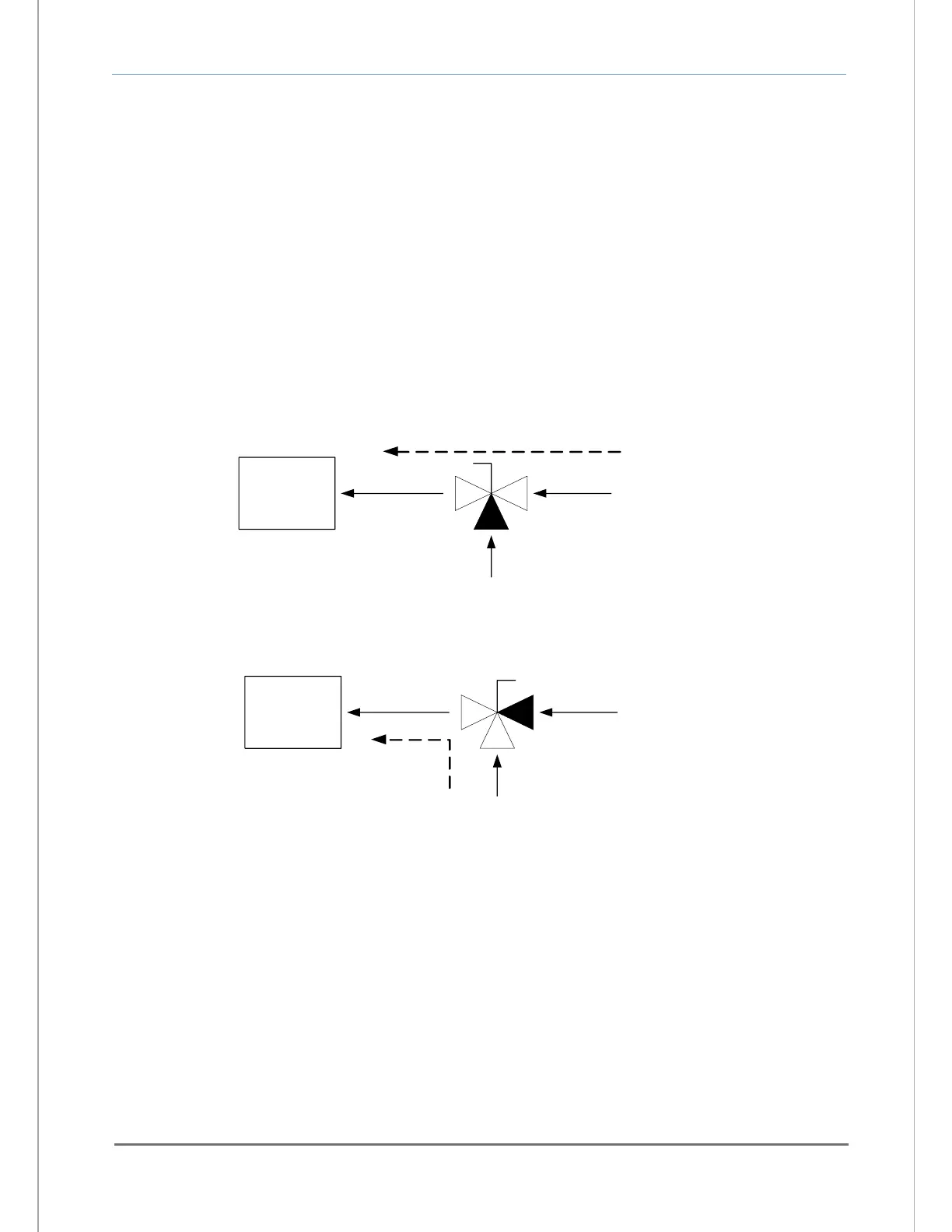

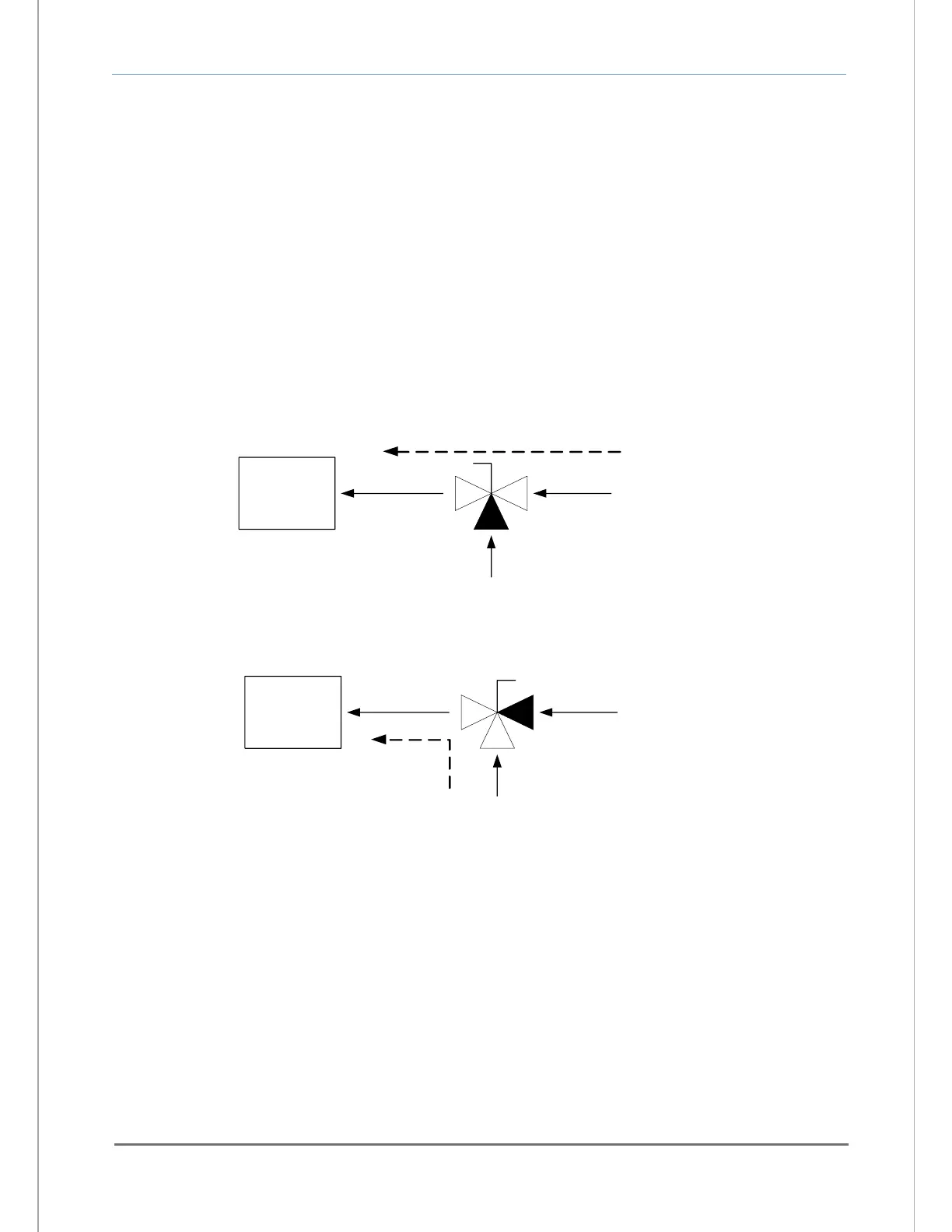

A fixed calibration port (Figure 11) may be implemented in the process sampling line by installing a 1/8" or

1/4" 3-way manual ball valve into the sampling line as in figure-9. Use 1/8" or 1/4" rigid tubing and 1/8"

MNPT fittings of a material compatible with process gas composition. Ensure that no grease, particulate,

or solvent is present in the tubing during installation. Use thread-tape to seal connections, and prevent

galling. Fix all sample tubing and connectors.

3.1.2.3 Sample exhaust port

Pneumatic connection to the measured process for sample extraction is made at either of the two

interchangeable 1/8" FNPT fitting around the side of the flow-through head, but opposite the installed

sample inlet port (section 2.1.2.2). For connecting the sample exhaust to vent, use 1/8" or 1/4" rigid

tubing and 1/8" MNPT fittings of a material compatible with process gas composition. Select a vent

location that is known to be at atmospheric pressure at all times. Use a minimum of 2-meters of tubing to

prevent back-flow of vent gas to the sensor. Ensure that no grease, particulate, or solvent is present in

the tubing during installation. Use thread-tape to seal connections, and prevent galling. Fix all sample

tubing and connectors.

Loading...

Loading...