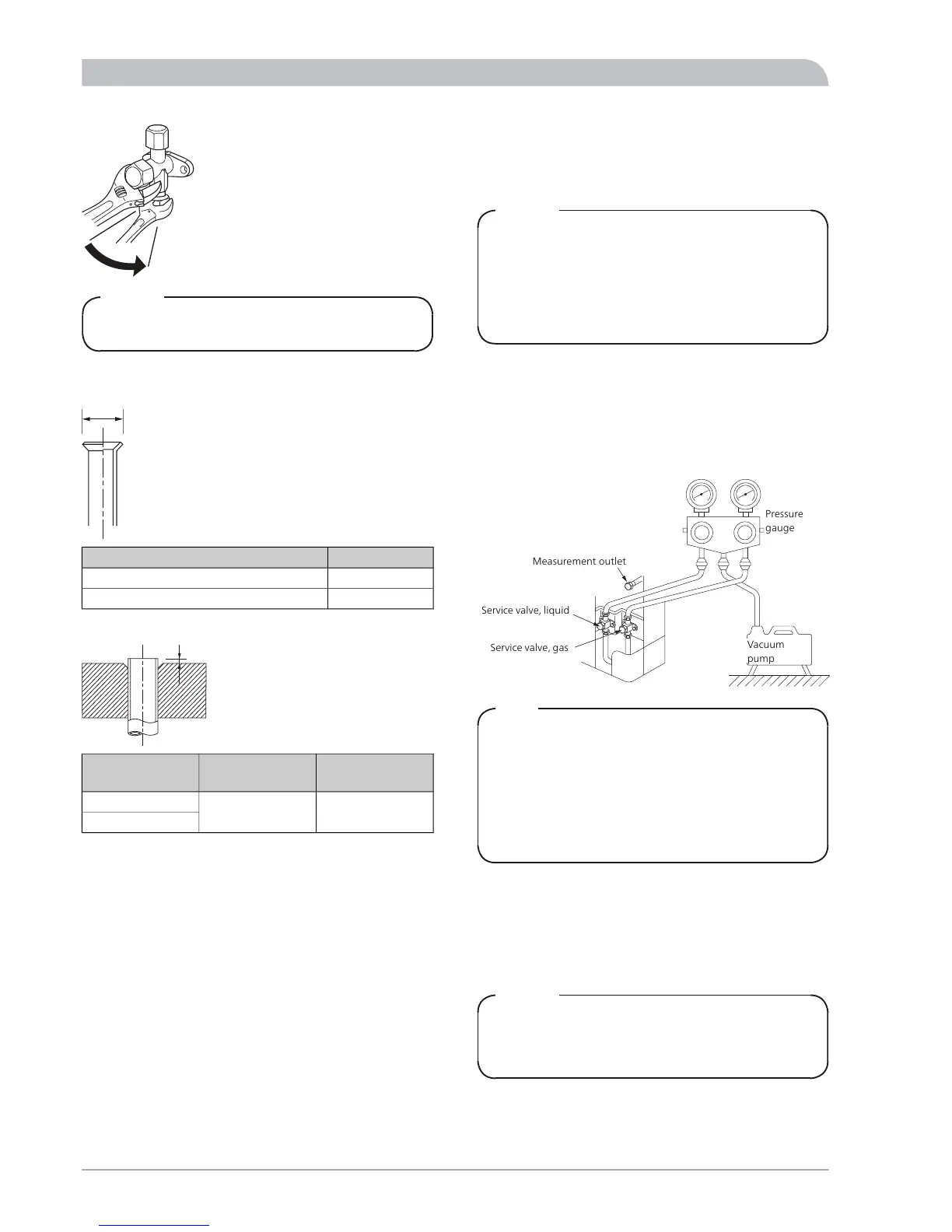

B, with a conven-

tional tool (mm)

B, with an R410A

tool (mm)

Outer diameter,

copper pipe (mm)

0.7~1.30.0~0.5Ø9.52

Ø15.88

(Follow instructions for the tool used.)

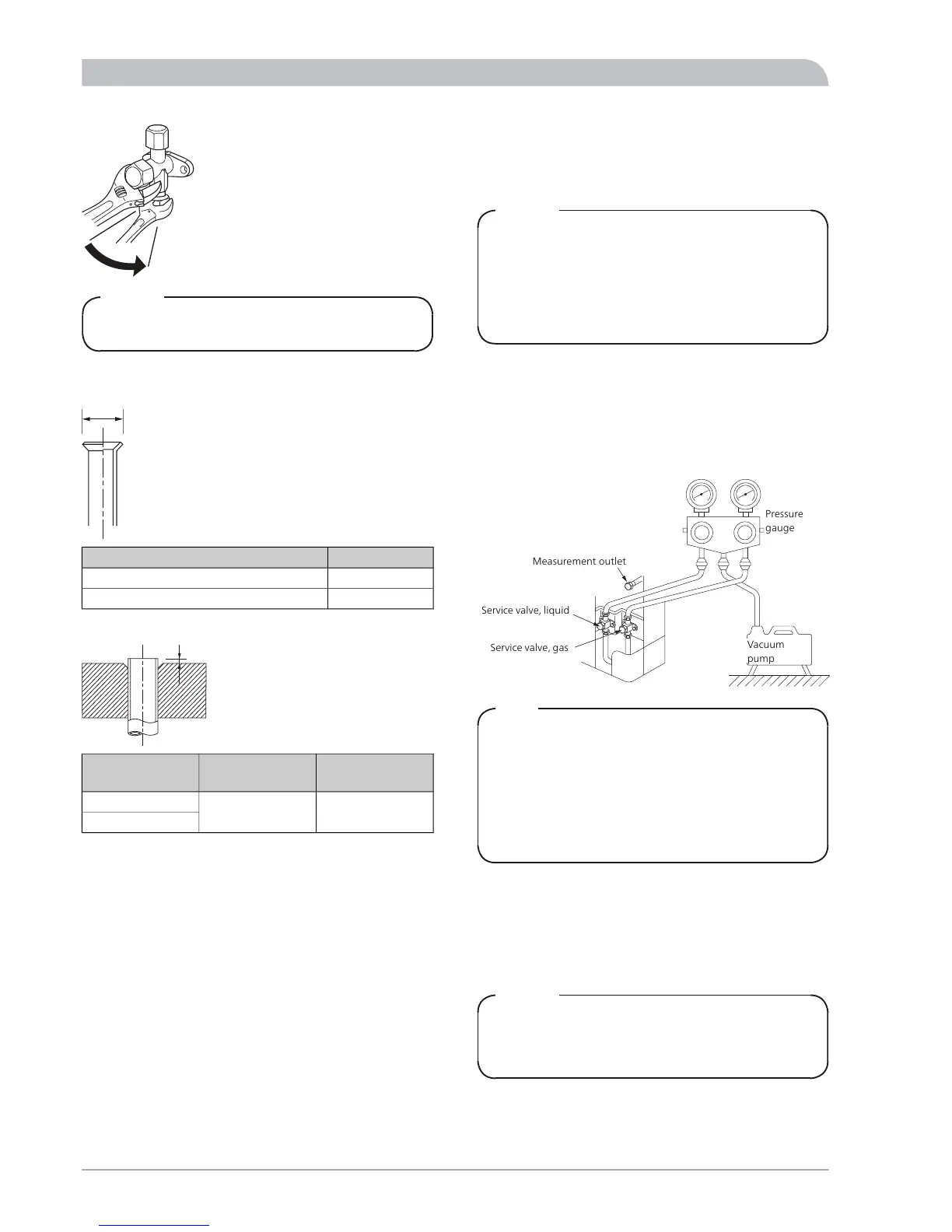

Pressure test and leak test

Both ACVM 270 and AMS 10 are pressure tested and leak

tested at the factory, but the pipe connections between

the products must be checked after installation.

NOTE

The pipe connection between the products must be

pressure tested and leak tested according to the ap-

plicable regulations after installation.

Under no circumstances must a type of medium other

than nitrogen be used when pressurising or flushing

the system.

Vacuum pump

Use a vacuum pump to evacuate all air. Apply suction for

at least one hour and end pressure after evacuation must

be 1 mbar (100 Pa, 0.75 Torr or 750 micron) absolute

pressure.

If the system has remaining moisture or a leak, the vacuum

pressure will rise after completed evacuation.

TIP

For a better end result and to quicken the evacuation,

the following points must be followed.

■

The connection lines must be as large and short as

possible.

■

Evacuate the system down to 4 mbar and fill the

system with dry nitrogen to atmospheric pressure

to the finish the evacuation.

Filling refrigerant

AMS 10 is delivered complete with the refrigerant required

for the installation of refrigerant pipes up to 15 m in

length.

If the length of the refrigerant pipes exceeds 15 m, extra

refrigerant must be added at a rate of 0.06 kg/m.

NOTE

For installations with refrigerant pipes up to 15 m in

length, no extra refrigerant in addition to the

provided amount needs to be added.

When carrying out pipe connections, pressure tests, leak

tests and vacuuming, the service valves (QM35, QM36)

can be opened, to fill the pipes and ACVM 270 with refri-

gerant.

NIBE™ SPLIT ACVM 27024

For the Installer

Pipe installation

Loading...

Loading...