Flow settings charge pump GP1 VVM 320

This function is used to check the flow between indoor

and outdoor units. The purpose of the function is to

be able to diagnose the fault in the event of suspected

flow related problems.

Program sequence:

■

Check that BT6 is less than 40*C otherwise the text

”Drain hot water to cool Water heater” appears.

■

Sets reversing valves to HW-mode.

■

Starts GP1 and runs at maximum speed.

■

Starts the compressor.

For on/off models the following applies: if the

compressor does not start within 10 minutes, the flow

setting is cancelled and information is given stating

that the compressor could not be started.

For inverter models the following applies: if the

compressor does not start or reach 55 hz within 10

minutes, the flow setting is cancelled and provides in-

formation stating that the compressor could not be

started/reach the desired frequency.

For 1-phase inverters, the phase that the 1-phase invert-

er is connected to is detected. A message is given stat-

ing that the 1-phase inverter is being detected. When

the phase has been detected the message ”Compressor

detected on phase L?” is shown. If the compressor could

not be detected the message ”Could not detect com-

pressor phase” is shown. This function may run during

the 5 minutes that the compressor is to run before the

flow checks below are started.

■

Ensure that the compressor has run for at least 5

minutes.

■

Shows blank screen with 5 minutes countdown.

■

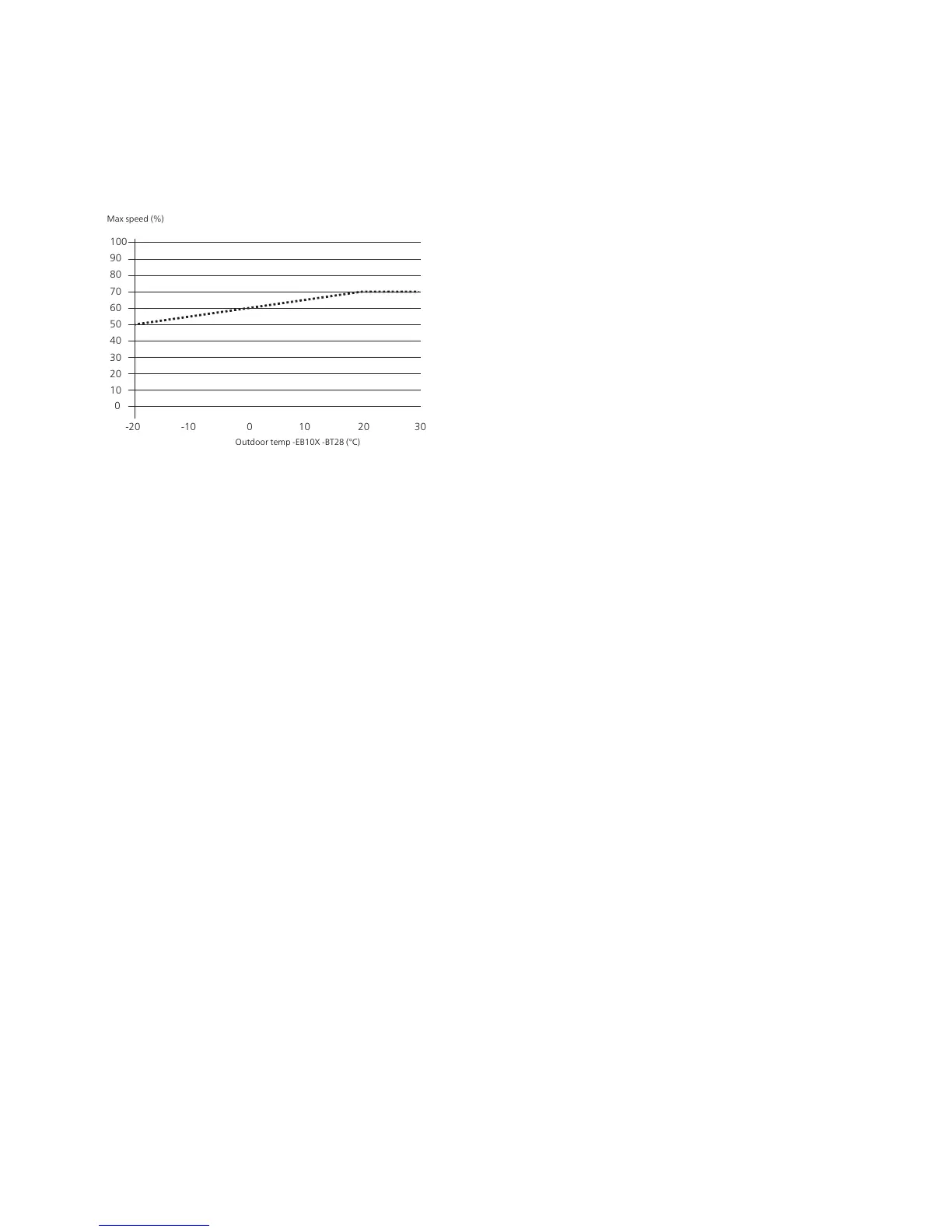

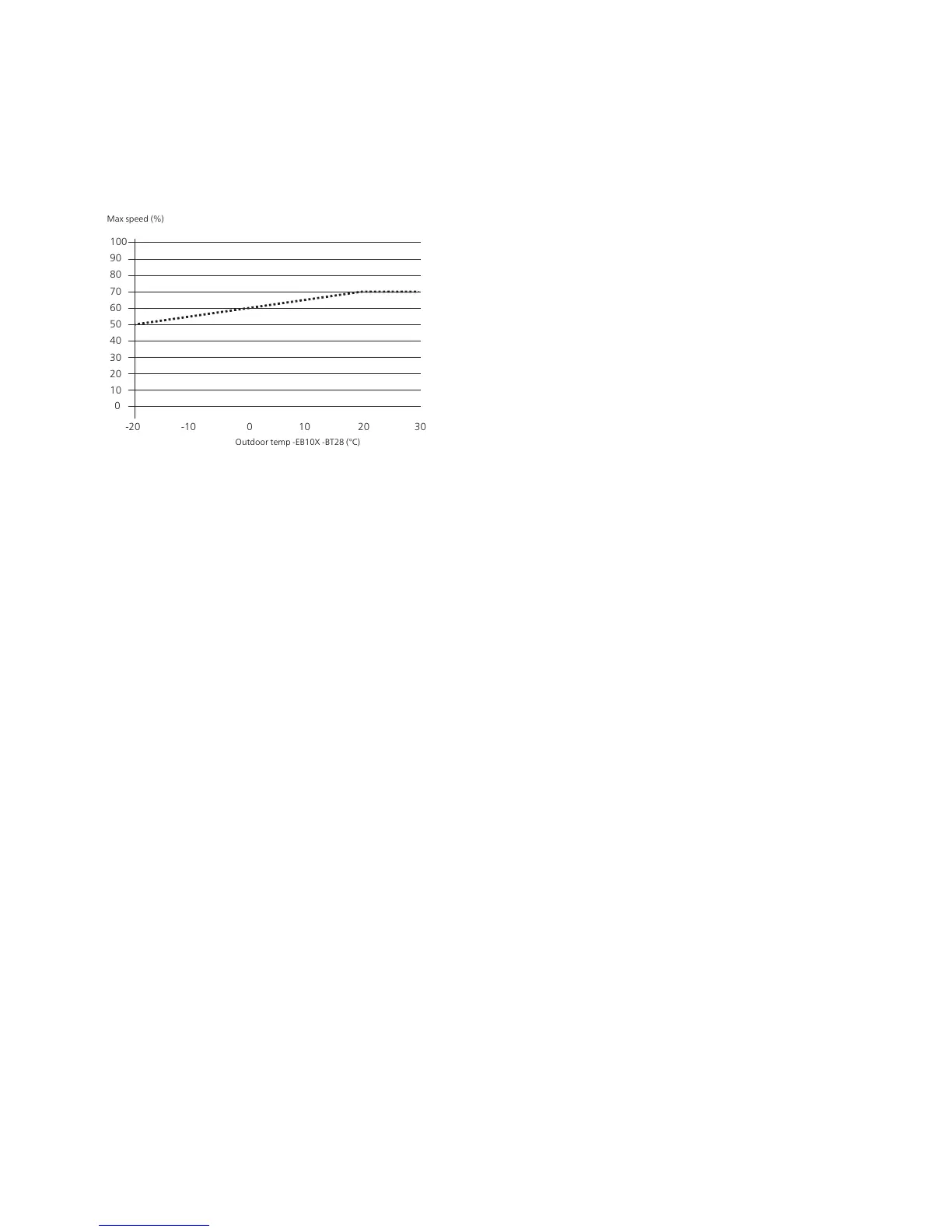

Shows highest recommended Δt for the given out-

door temperature.

■

Shows relevant Δt above BT12 and BT13 (the updat-

ing frequency is 10 seconds) and calculates an aver-

age value over 10 seconds.

■

The user adjusts the flow

■

Increase/Decrease the flow indicated in the display

depending on the conditions for the selected heat

pump (slave1)

■

When the condition has been met for 1 minute,

”Pump setting OK” appears.

■

When the user exits the menu, control of the charge

pump is released again and returns to the same op-

erating mode as for the setting.

Dimensioned flow for VVM 320 is 12 kW at 9 °C. It gives

a flow corresponding to 1150 litres. The coil in the

water heater can be deemed to correspond to the

pressure drop in the radiator circuit. For smaller external

parts, F2030-7 and F2040-8, 20% less flow than the

dimensioned flow is permitted.

Hot water

If hot water in menu 5.11.1.2 is set to auto, GP1 controls

according to ”Determining the speed using regulator”,

otherwise after the manually set speed.

POOL

If pool in menu 5.11.1.2 is set to auto, GP1 controls

according to ”Determining the speed using regulator”,

otherwise after the manually set speed.

Defrosting

Any control is stopped

During defrosting the speed is set to a maximum

of:

■

The average value of the speed GP1 that the com-

pressor ran to meet the heating demand of the cur-

rent defrosting/ manually set speed for the 2 last

minutes.

■

50 %

During tank defrost the speed is set to a maximum

of:

■

The average value of the speed GP1 that the com-

pressor ran to meet the heating demand of the cur-

rent defrosting/ manually set speed for the 2 last

minutes.

■

70 %

At completed defrosting:

■

If GP1 is controlled, it returns to 30 % higher speed

than it had just before defrosting. The exception is

if priority shift occurs during/in conjunction with

defrosting. This priority shift is then treated as a

normal shift.

■

If GP1 is not controlled, GP1 returns to the speed set

for respective demand according to menu 5.11.1.2.

During passive defrosting:

■

GP1 controlled according to operating mode

Auto/Intermittent in menu 5.11.1.2

If GP1 is stationary regardless of operating mode, the

pump exercising function is used.

In emergency mode, GP1 is run without PWM signal,

which means that it runs at maximum speed.

21Chapter 4 | Description of functionsNIBE™ VVM 320

Loading...

Loading...