TITAN 912L Linear Actuator

Installation Reference Manual

1010

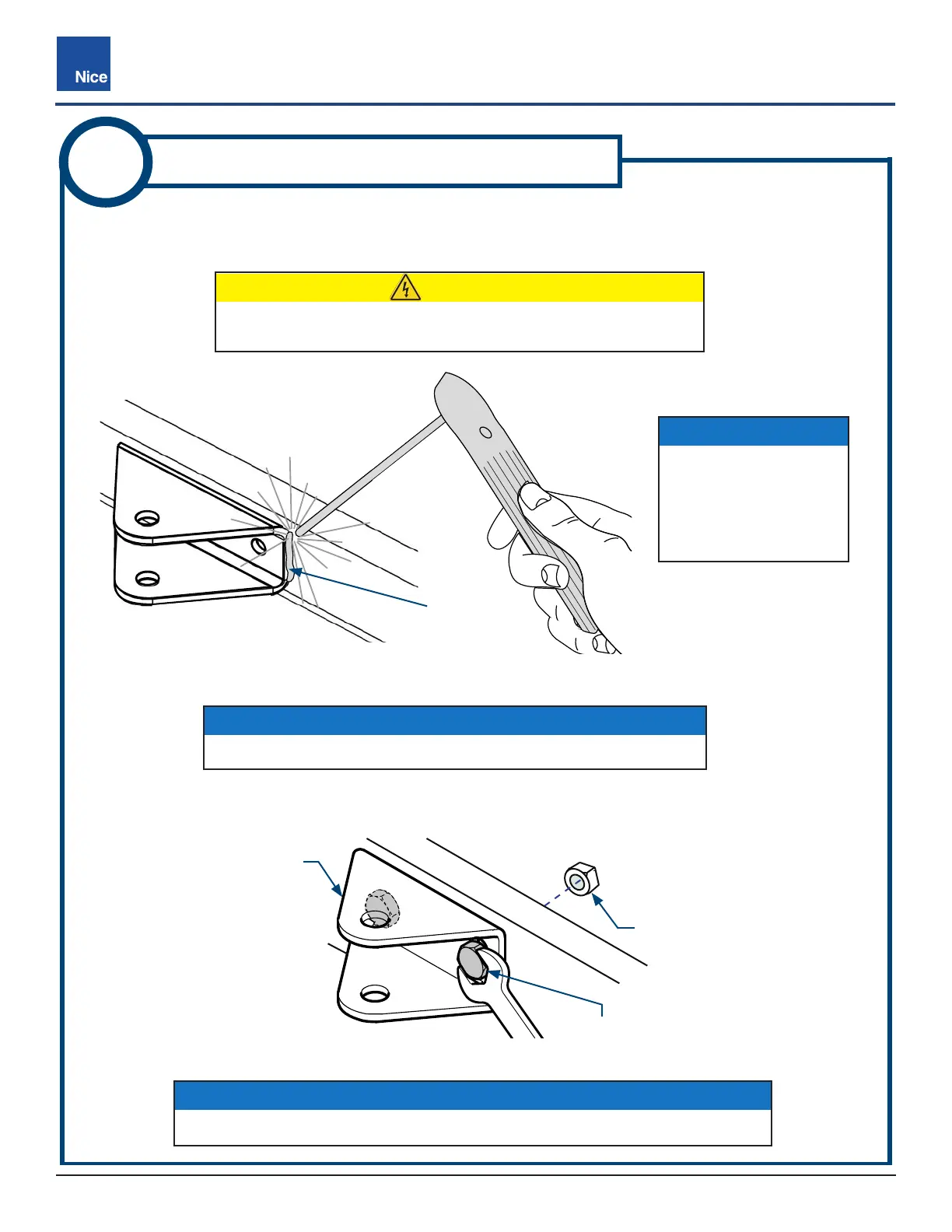

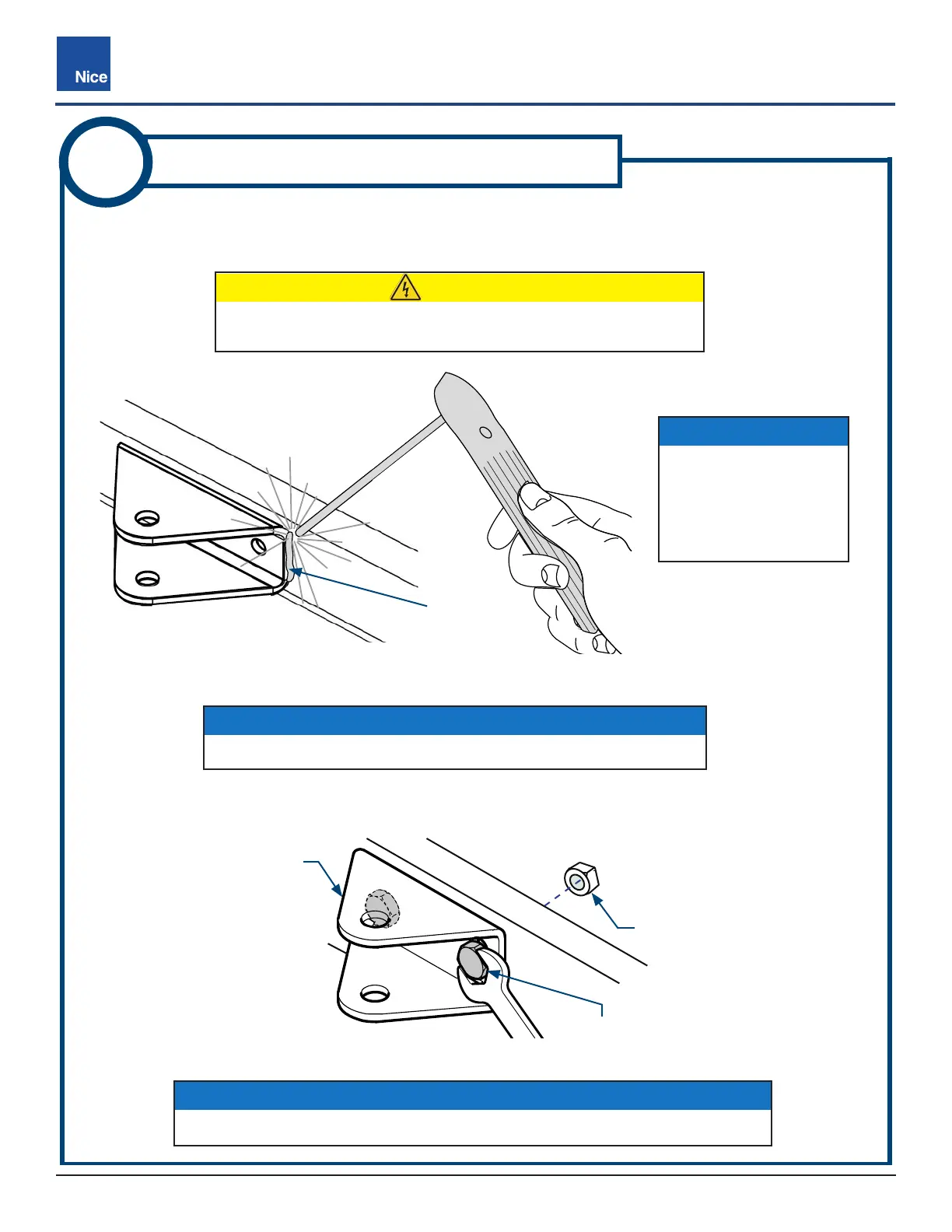

1. Weld the gate bracket to the gate supporting structure (FIG-5A) or use supplied 3/8” bolts and

nuts from kit (FIG-5B).

2. If welding is not possible, drill two holes to match bracket mounting holes and afx with two

3/8”x2.5” screws and 3/8” nuts included in the kit (FIG-5B).

FIG-5A: GATE BRACKET WELDED TO GATE

FIG-5B: GATE BRACKET AND HARDWARE (BLACK BRACKET SHOWN)

5

AFFIX GATE BRACKET TO GATE

GATE BRACKET

3/8”x2.5” HEX BOLT (x2)

WELD

3/8” NUT (x2)

IMPORTANT!

Ensure bracket centerline is 1/2” above the top of the pivot arm.

IMPORTANT!

Use a bubble level to assure after mounting that actuator is level and plumb.

CAUTION

Never weld parts to the gate or posts when the control board

is powered to avoid irrepairable damage to the circuit board!

NOTICE

Attach gate bracklet

only to structural

supports. If unsure of

exact bracket location,

tack weld or clamp until

gate can be tested.

www.ApolloGateOpeners.com | (800) 878-7829 | Sales@ApolloGateOpeners.com

Loading...

Loading...