Do you have a question about the Nilfisk-Advance Captor 4800 and is the answer not in the manual?

Identifies the specific models covered by this manual.

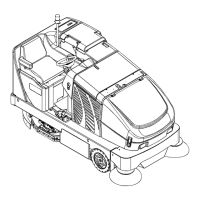

Provides an overview of the manual and product.

Details on obtaining repair parts and service from authorized centers.

Location and importance of the machine's nameplate.

Instructions for using the hopper safety support for maintenance.

Safety precautions and procedures for jacking the machine.

Explanation of hazard symbols and their meanings.

Essential safety guidelines for machine operation and maintenance.

Key specifications applicable to all Captor models.

Intervals and items for regular machine maintenance.

Procedures to follow after each use of the machine.

Guidelines for lubricating machine components.

Procedures for checking and servicing the engine air filter.

Procedures for checking and maintaining hydraulic oil levels.

List of operational checks for the PM checklist.

List of visual checks for the PM checklist.

Procedure to test the electronic control system for faults.

Troubleshooting steps for when the engine fails to crank.

Checks related to the electrical control circuit for engine starting.

Guidance for diagnosing steering system issues.

Visual representation of the steering system's hydraulic layout.

A checklist for diagnosing hydraulic wheel drive problems.

Steps for troubleshooting sweeping system issues.

Diagnostic steps if the main broom fails to rotate.

Electrical checks for the main broom not turning issue.

Procedures for diagnosing hopper system malfunctions.

Steps to troubleshoot when the hopper fails to raise.

Electrical diagnostic steps for hopper raise issues.

Guidance for resolving scrub system problems.

Steps to troubleshoot a non-lowering scrub deck.

Electrical checks for scrub deck lowering issues.

Steps to diagnose recovery system faults.

Troubleshooting for a non-operational vacuum motor.

Electrical checks for vacuum motor operation.

Technical specifications for the GM 1.6L engine.

Regular maintenance tasks for the engine.

General guidance for diagnosing hydraulic system issues.

Information on pressure readings at test ports.

Identifying the physical location of electrical components.

A table detailing hydraulic valve functions and switch states.

Adjusting the delay for scrub motor turn-off.

Adjusting the delay for vacuum motor turn-off.

Adjusting the delay for broom motor turn-off.

Overview of AXP/EDS system components.

Key components of the main solution delivery system.

Procedures for preparing and using the detergent system.

| Brand | Nilfisk-Advance |

|---|---|

| Model | Captor 4800 |

| Category | Scrubber |

| Language | English |

Loading...

Loading...