26

6.2 PASSIVE ROLL SYSTEMS

The following is a checklist for troubleshooting Passive Roll systems.

Ensure the rod is mounted perpendicular (90) to the sensor.

- if the sensor is straight vertical, the rod must be horizontal

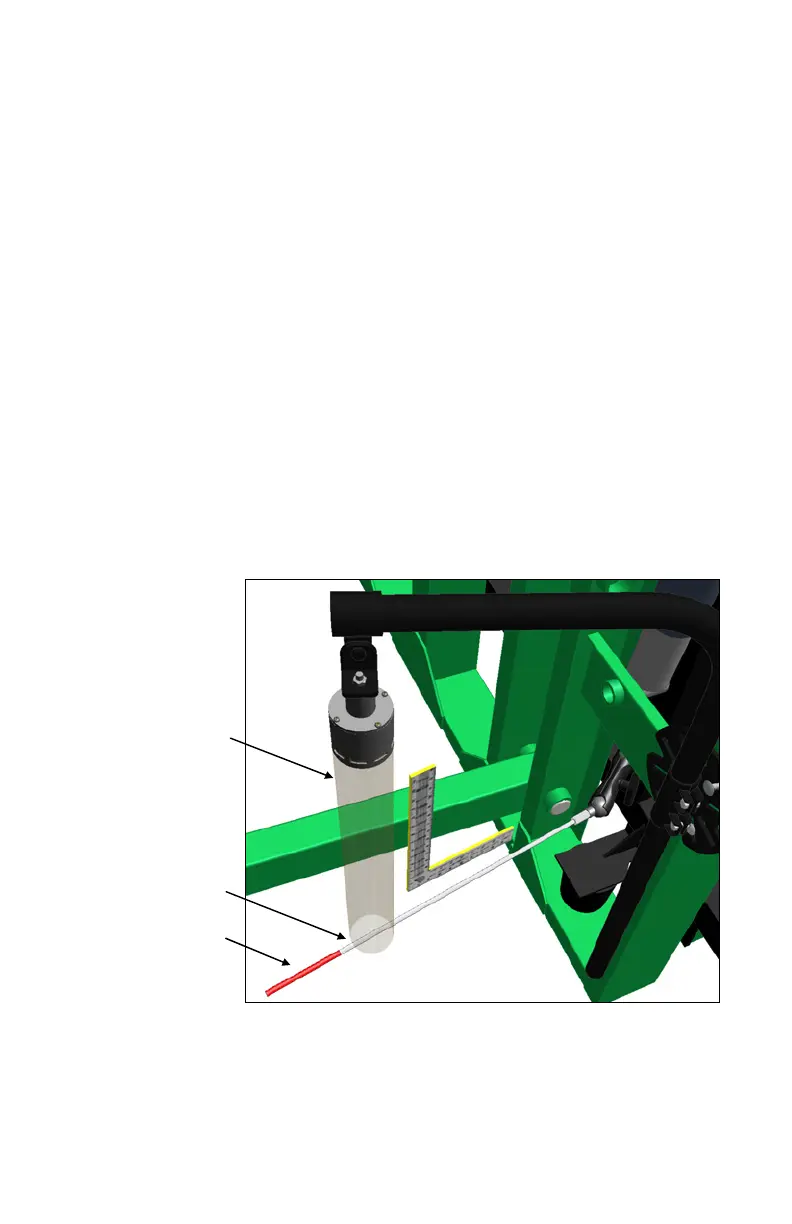

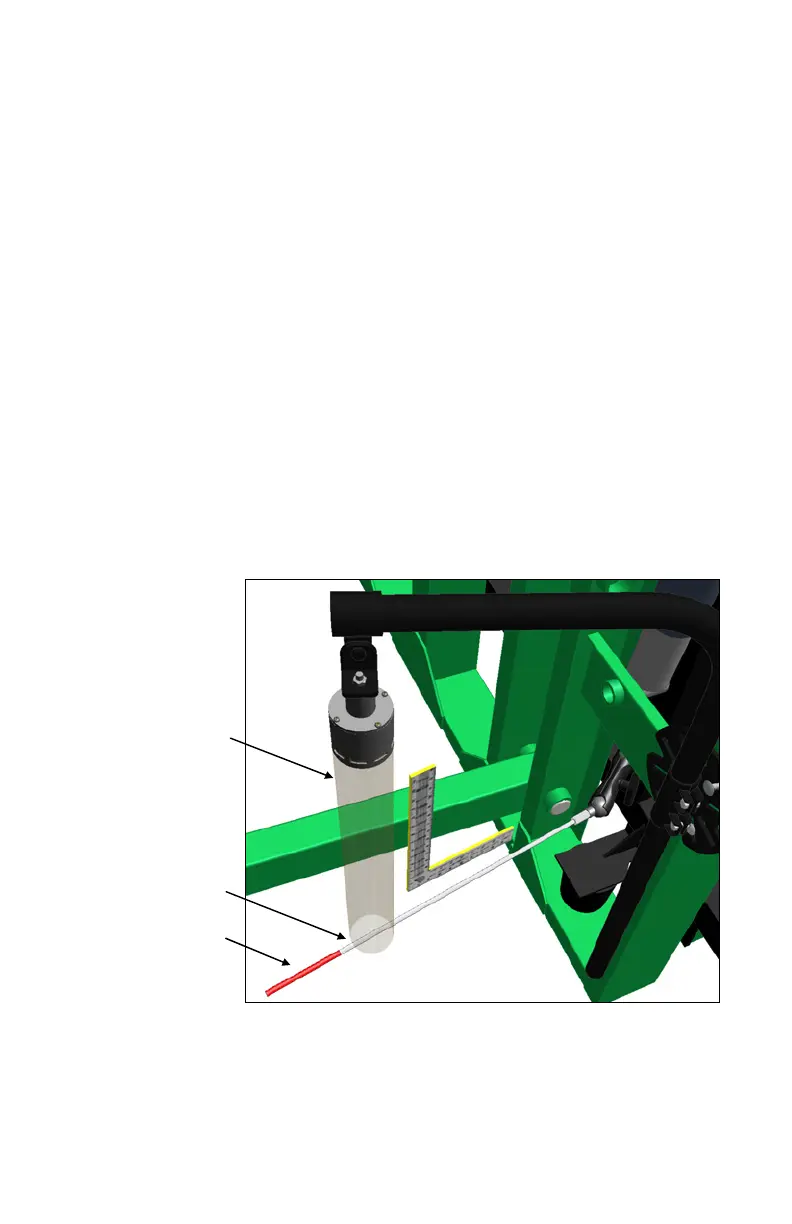

(Figure 5)

Distance from the sensor to the target should be 20 ( 2) inches (Figure

5).

The target rod should cross the sensor’s central axis. The sensor

alignment tube (Figure 3) will help make these adjustments.

Ensure none of the parts collide with any part of the machine during

folding or operation.

- if desired, the Passive Roll rod may be trimmed, but no shorter

than 2 inches past the center of the sensor.

Ensure the adjustable target mount is tight to prevent rotation.

Ensure the sensor cable does not pull tight during operation or folding,

causing the sensor to be pulled out of alignment.

Figure 3 – Sensor Alignment Tube

Sensor Alignment

Tube

Target Rod

Cut Rod Portion

(2" Past Alignment Tube)

Loading...

Loading...