28

Instructions for the installer

3.6 Checking combustion eciency

3.6.1 Flue cleaning function

• The boiler features a ue cleaning function which must be used to measure combustion eciency during operation and to adjust the

burner.

• To activate the ue cleaning function, press and hold the buttons “Info” and “Reset” simultaneously for 5 seconds. The ow temperature and

the

symbol are shown on the LCD.

• When the ue cleaning function is activated with the boiler in WINTER or SUMMER mode, the boiler performs the ignition sequence and

then operates at a xed power output predetermined by the parameter P7 (maximum CH output).

• To exit the ue cleaning mode, press “Reset” or wait 15 minutes.

3.6.2 Measurement procedure

In order to verify combustion eciency the following measurements must be implemented:

• assess combustion air from the boiler installation room;

• assess ue gas temperature and CO2 from the special sampling port passing through the ue gas venting duct.

If sampling port is not present, it must be provided by the boiler operation and maintenance manager in compliance with the prevailing

regulations and standards.

Sampling port must be equipped with a special sealing and must be correctly closed after each reading.

Allow boiler to reach working temperature before taking any measurement.

3.7 Connection to gas mains

Cross-section gas pipe size must be chosen depending on its length, layout pattern, gas ow rate.

Gas supply pipe cross-section must be equal or greater than boiler gas pipe.

DANGER

Comply with installation standards enforced in the country where the boiler is installed which are considered as fully transcribed

in this booklet.

Remember that before operating an indoor gas distribution system and before connecting it to a meter, it must be checked for

leaks.

If some system parts are not visible, the leak test is to be carried out before the pipes are covered.

Leak test is NOT to be carried out employing ammable gas: use air or nitrogen for this purpose.

Once gas is in the pipes, leak test by a naked ame is forbidden; use specic products available on the market.

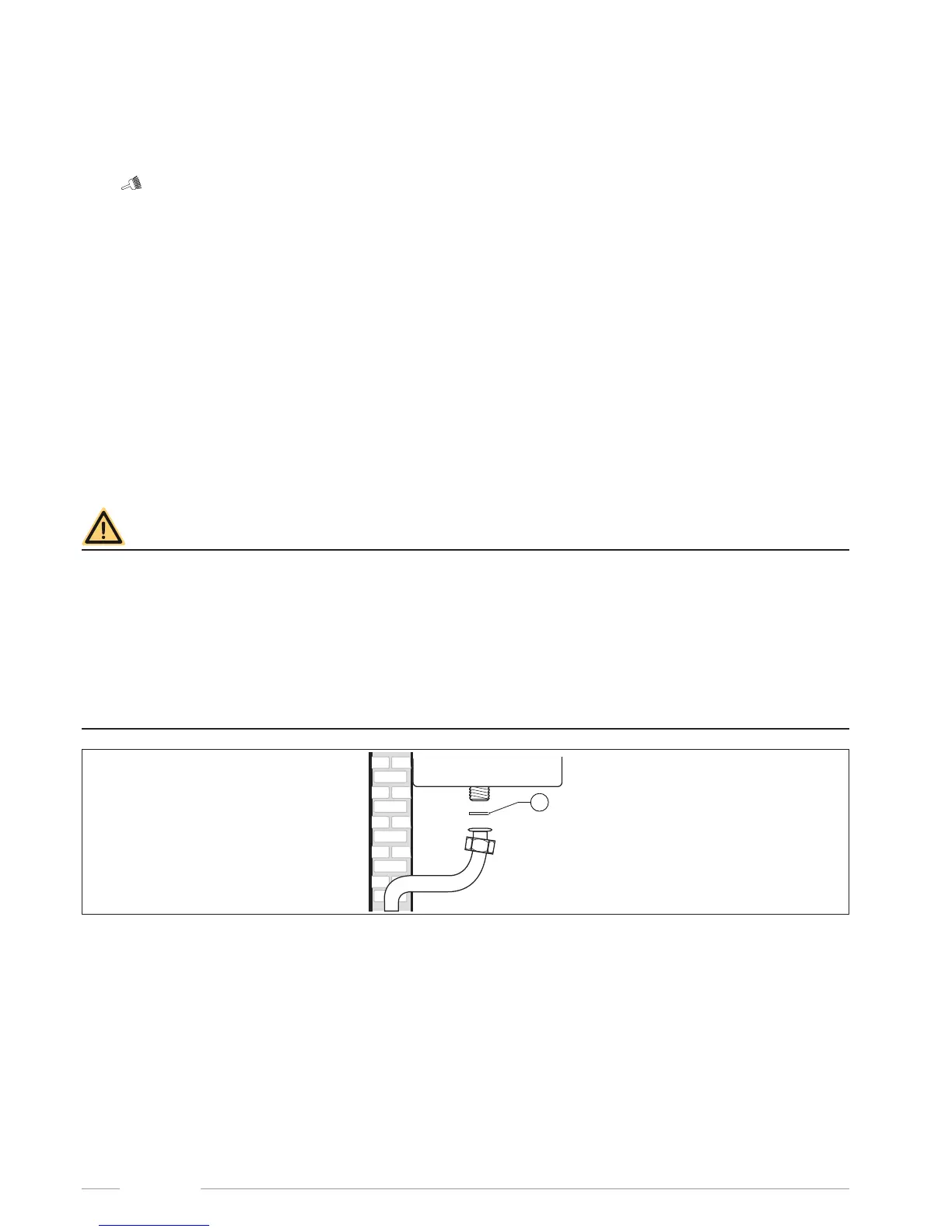

When connecting the boiler to gas supply network, it is COMPULSORY to install an appropriately sized gasket (A) made from

suitable material (see Fig. 8 Connection to gas mains).

The boiler gas inlet coupling is NOT suitable for hemp, teon tape or similarly made gaskets.

A

Fig. 8 Connection to gas mains

Loading...

Loading...