36

Instructions for the installer

3.14 Starting up the boiler

3.14.1 Preliminary checks

Before starting the boiler, check that:

• The ue gas venting duct and the relevant terminal are installed in conformity with the instructions: with the boiler operating, there must

be no leakage of combustion by-products from any of the gaskets.

• The supply power to the boiler must be 230 V ~ 50 Hz.

• the heating system is correctly lled with water (pressure gauge reading 1÷1.3 bar).

• Any shut-o cocks in the system pipes are open.

• the mains gas type is correct for the boiler calibration: convert the boiler to the available gas if necessary (see Adaptation to other gas types

and burner adjustment on page 39). This operation is to be exclusively carried out by qualied personnel.

• The gas supply cock is open.

• There are no fuel gas leaks.

• The main switch installed adjacent to the boiler is turned on.

• The 3-bar safety valve is not stuck.

• There are no water leaks.

3.14.2 Switching on and switching o

To switch the boiler on and o, refer to the “Instructions for the User” (see Instructions for the user on page 8).

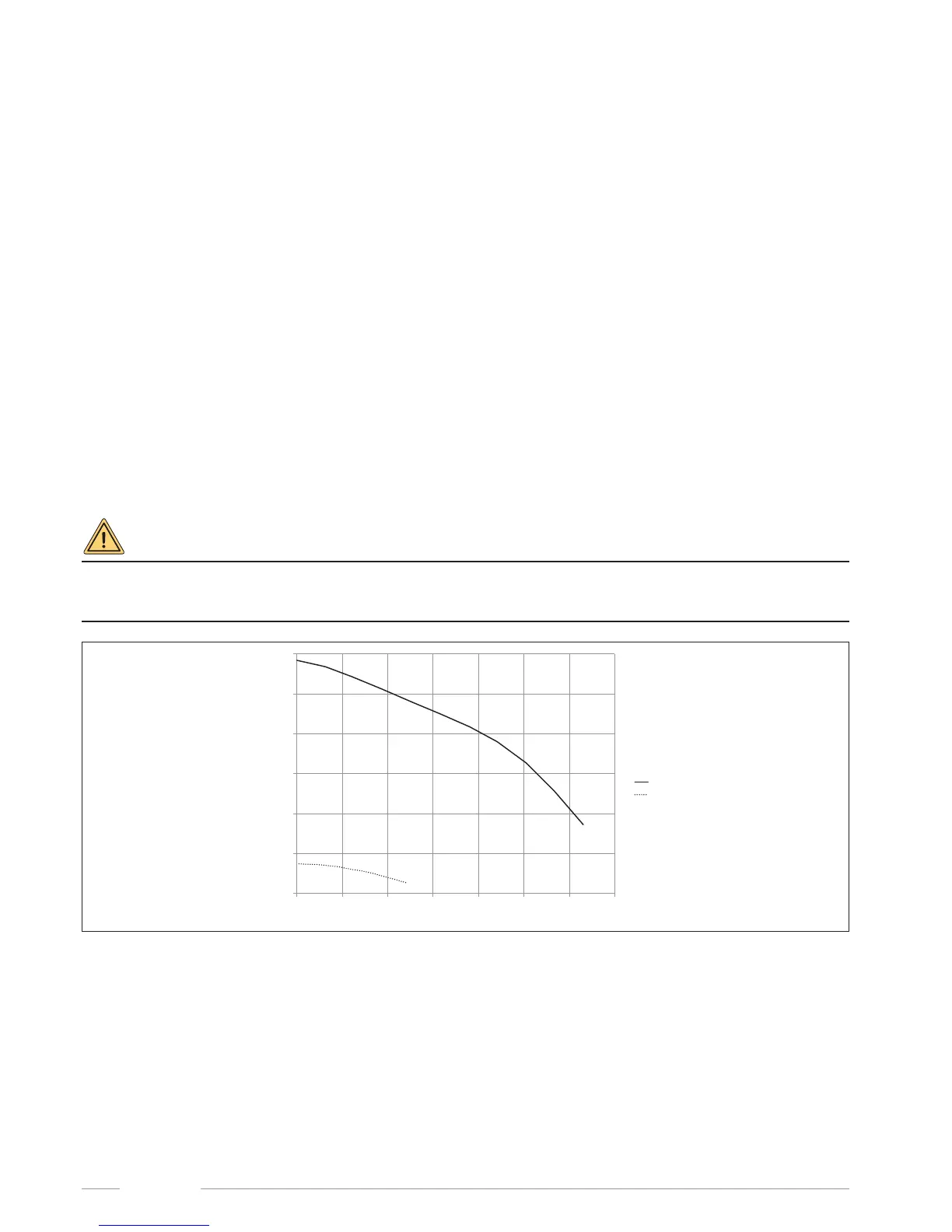

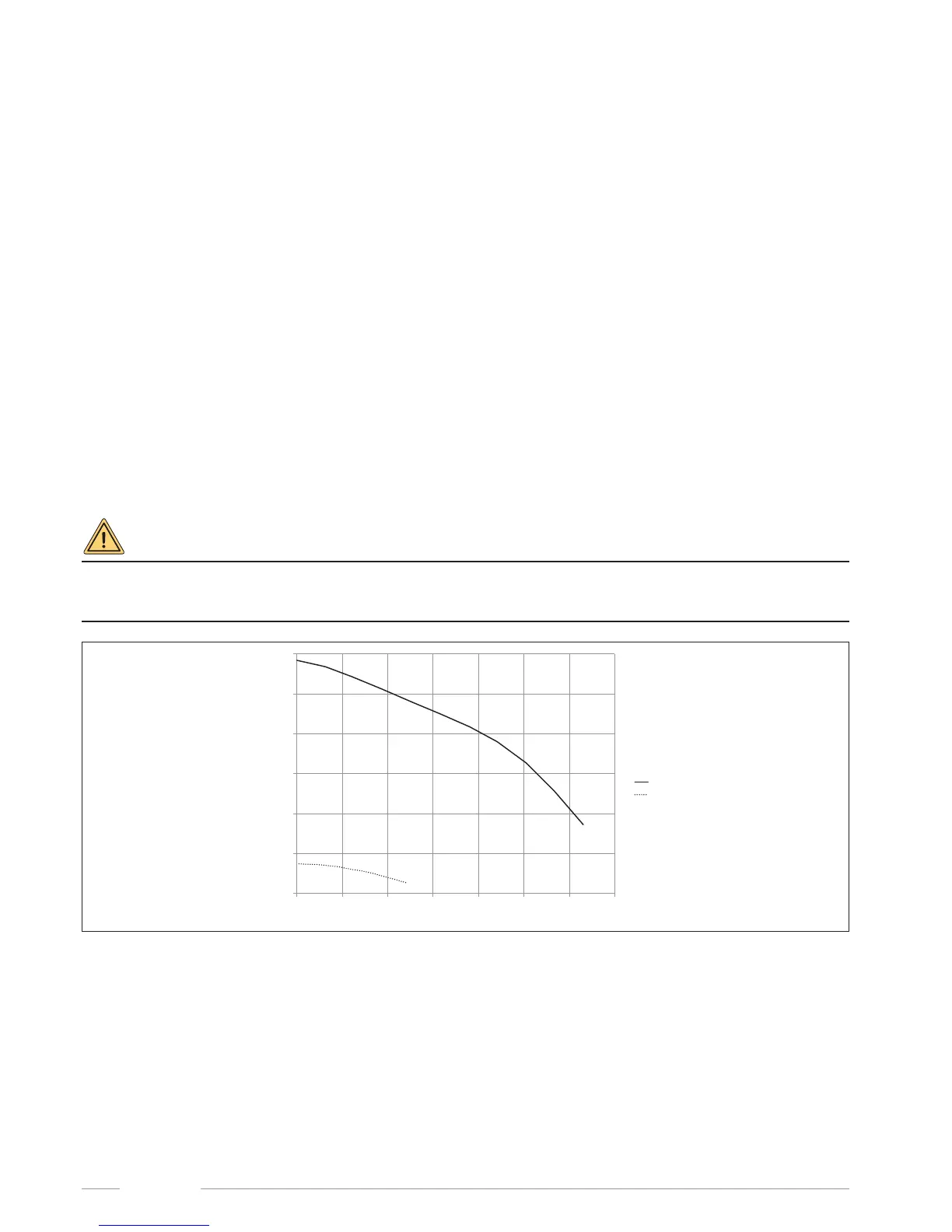

3.15 Available head

The boiler is equipped with a high-eciency circulation pump.

Circulation pump speed can be set during heating and DHW modes, editing the relevant "super technical" parameters of the boiler.

WARNING

Circulation pump operating speeds are set during production.

For a correct operation of the boiler, it is recommended not to change factory setting.

Should it be necessary to change circulation pump settings, contact a Service Centre.

0

100

200

300

400

500

600

0 200 400 600 800 1000 1200 1400

H

Q

100%

30%

Fig. 10 Available head

Q .................Flow rate (l/h)

H .................Available head (mbar)

Loading...

Loading...