- 26 -

ROUTINE INSPECTION AND MAINTENANCE

1. VISUAL INSPECTION

Detect a potential problem early.

FASTENERS

Inspect all fasteners. Retighten as necessary. See page 34 for torque values.

WELDS

Check for cracks, repair as necessary.

HOSES AND TUBING

Check for oil leaks, loose clamps and hose abrasion.

HYDRAULIC OIL

MAINTAIN A CLEAN HYDRAULIC SYSTEM

If non-petroleum oil is used, contact NPK Service Department for compatibility.

Keep hoses clean and capped when dismounting or storing hammer.

Change oil and filters as recommended by carrier manufacturer. Periodic oil

sampling is recommended.

2. DEMOLITION TOOL LUBRICATION

Important: It is imperative that

grease is maintained in the tool

bushing contact area at all times.

This may require hourly greasing

depending on job conditions.

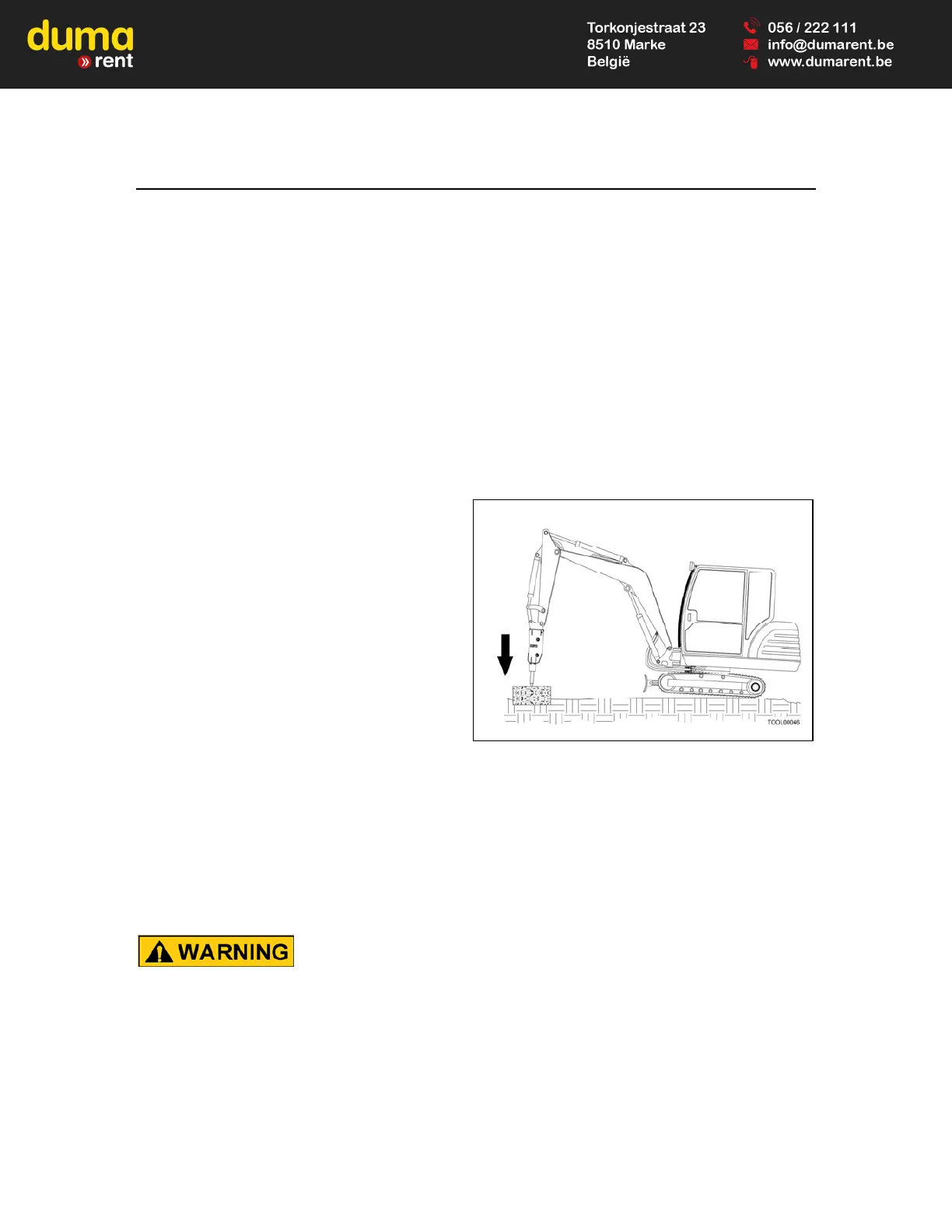

Important: The hammer must be in a

vertical position with down force

applied to push the tool all the way in.

This prevents grease from entering

piston impact area. Pump grease

into hammer until grease is seen

coming out between the tool and

tool bushing, see page 13.

USE A GOOD QUALITY, HIGH TEMPERATURE EP#2 GREASE CONTAINING ANTI-

WEAR ADDITIVES, SEE PAGES 13, 14, and 15.

If machine is equipped with an AUTOLUBE System, check grease reservoir daily.

3. TOOL and TOOL BUSHING WEAR

Check the tool and tool bushings for damage, wear or deformation on a regular

weekly basis. Replace the tool and/or bushings when wear exceeds the maximum

clearance limit, see page 30.

Do not hard face or sharpen the tool point with a cutting torch. Excessive heat

from torching or welding causes embrittlement, breakage, and flying pieces.

Resharpen only with a surface grinder or milling machine using sufficient

cooling.

Please consult your authorized NPK Dealer or NPK Service Department for

additional information.

Loading...

Loading...