- 30 -

TOOLS

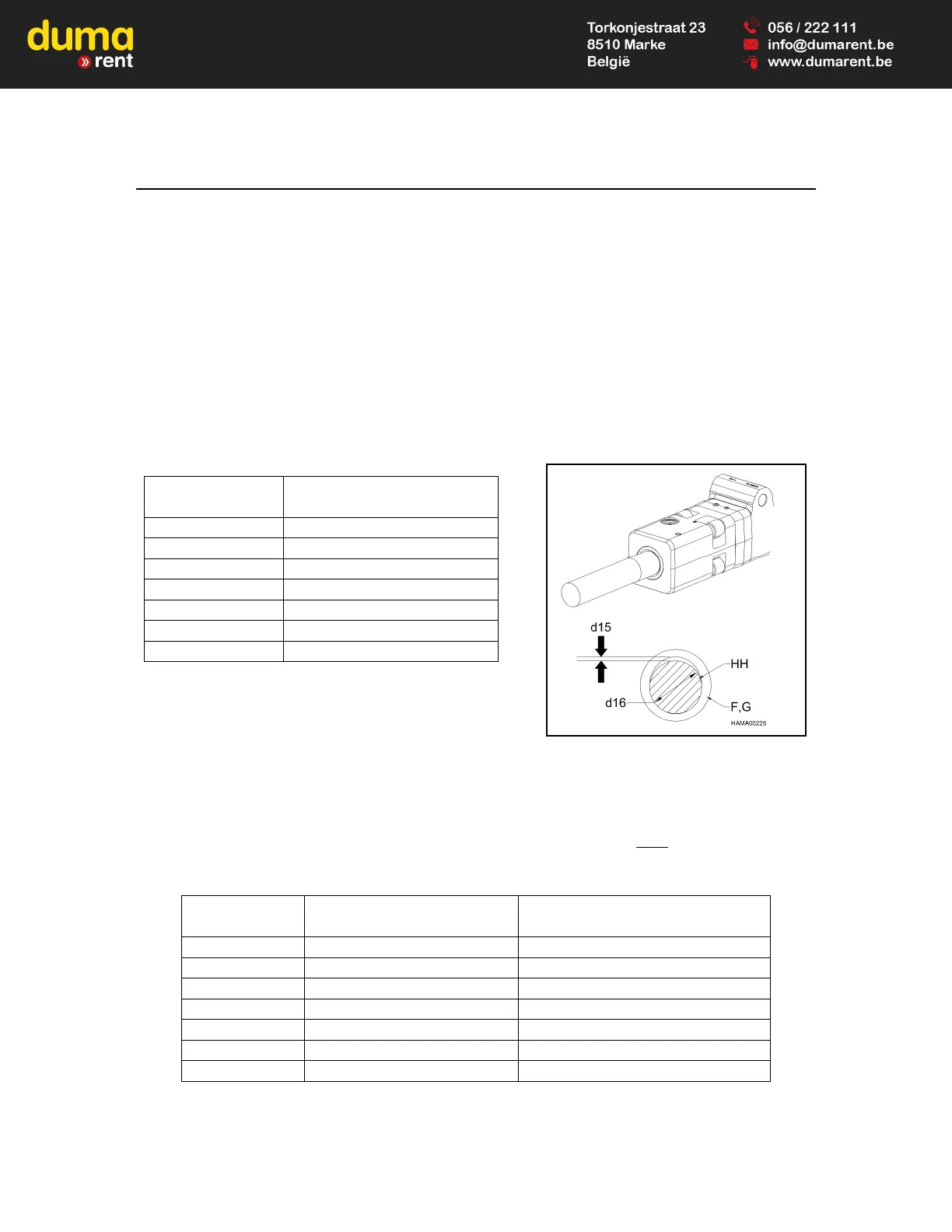

MAXIMUM TOOL TO TOOL BUSHING CLEARANCE

Replace the tool bushing (F,G), and/or tool (HH), when the tool to bushing gap reaches

the maximum clearance. To determine whether the bushing or tool requires

replacement, follow the instructions and charts shown below:

Step 1

Measure the tool to bushing gap (d15) with the hammer horizontal, as illustrated below.

If the clearance is at or greater than the charted maximum clearance, then move on to

the next steps.

MODEL

MAXIMUM CLEARANCE

INCH (mm) (d15)

GH06 1/4 (6.5)

GH07 1/4 (6.5)

GH1 1/4 (6.5)

GH2 / GHS2 1/4 (6.5)

GH3 1/4 (6.5)

GH4 1/4 (6.5)

GH6 3/8 (10)

Step 2

Remove the tool from the tool holder. Measure the diameter (d16) of the bearing

surface of the tool (HH), which is located on each side of the retaining pin groove. The

minimum tool diameter is compared to a new tool bushing (F,G) only. If the tool is at or

below the charted value, the tool must be replaced.

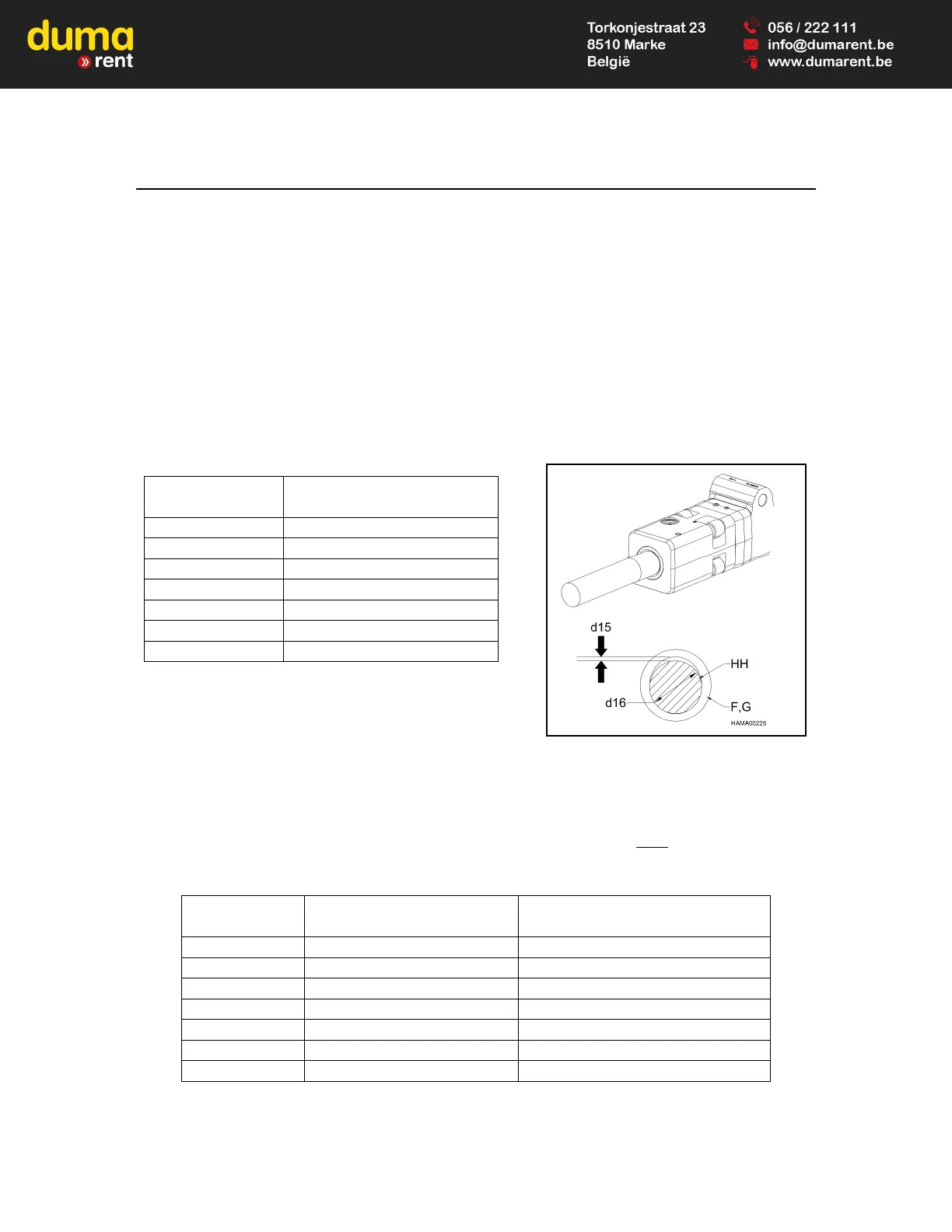

MODEL

NEW TOOL DIAMETER

INCH (mm)

MINIMUM TOOL DIAMETER

INCH (mm)

GH06 1.63 (41.4) 1.43 (36.4)

GH07 1.83 (46.6) 1.63 (41.4)

GH1 2.23 (56.6) 2.02 (51.4)

GH2 / GHS2 2.58 (65.6) 2.38 (60.4)

GH3 2.98 (75.6) 2.81 (71.4)

GH4 3.37 (85.6) 3.2 (81.4)

GH6 4.16 (105.6) 3.8 (96.4)

Loading...

Loading...