91

Part 1 - General Safety Information

Part 14 - Maintenance

7. Check condensate piping for sagging and/or leakage. Repair any

sags or leaks before restoring power to the boiler.

8. If the boiler has a condensate pump, ensure the pump operates

properly before considering maintenance complete.

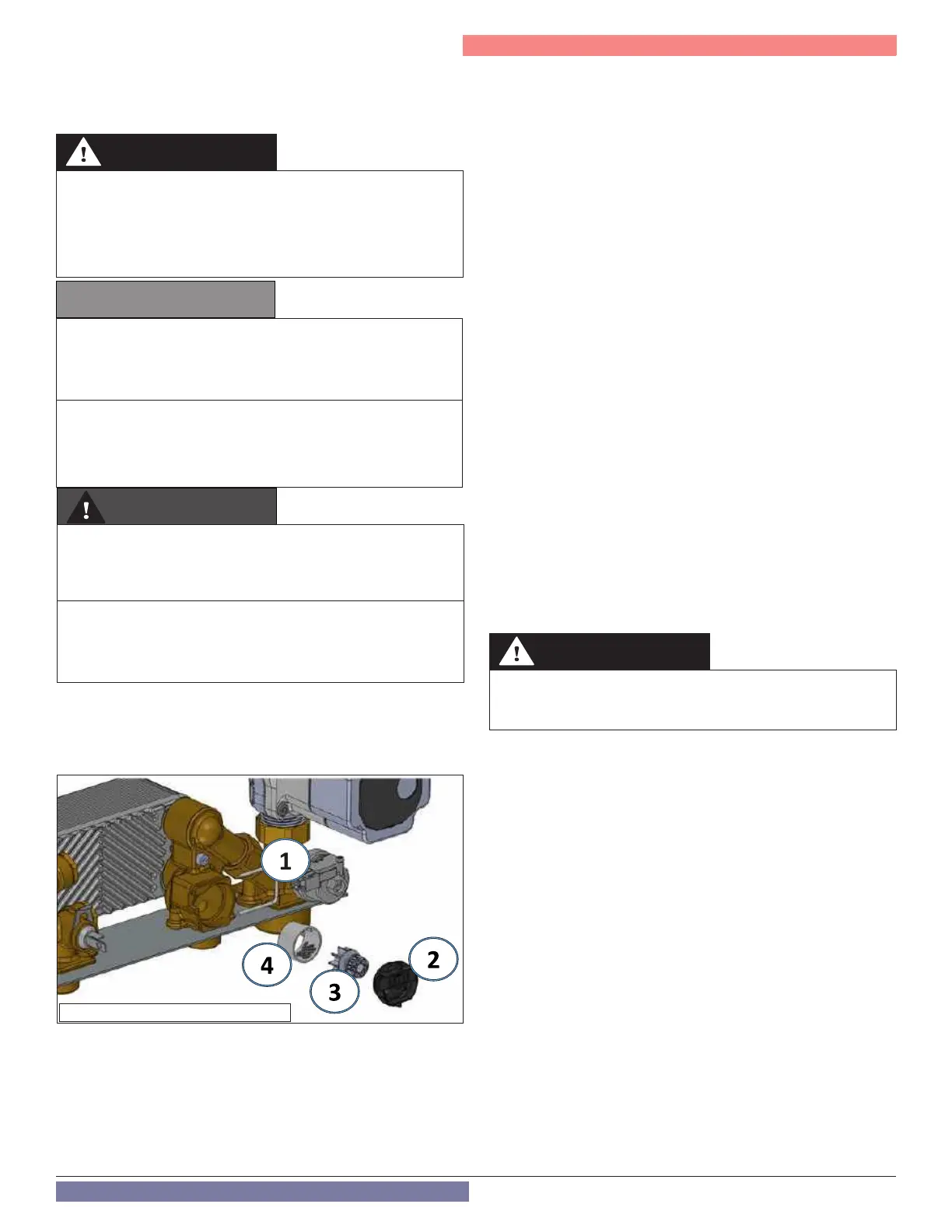

Cleaning the DHW Filter (Combi Models ONLY)

1. Remove the clip on the ow meter (1).

2. Remove the ow meter cap (2).

3. Remove the ow meter turbine (3).

4. Remove and clean the lter (4).

5. Clean the lter with a toothbrush and clean running water.

6. Reinstall the DHW inlet lter.

7. Rell the DHW circuit following the lling and purging instructions

in this manual.

8. Restore gas and power to the boiler.

When servicing is complete, make sure the siphon cap and retaining

clip are replaced securely. The condensate trap assembly MUST

BE PROPERLY INSTALLED according to these instructions when

operating the boiler. Operating the boiler without the condensate

trap assembly will cause ue gases to leak and result in serious

personal injury or death.

DANGER

WARNING

Ensure the combi boiler DHW heating system has been valved

off from the system and drained BEFORE attempting to remove

the DHW lter. Failure to do so could result in property damage,

serious personal injury, or death.

Water drained from the boiler could be scalding hot. Wait for the

boiler to cool before draining water, and take precautions when

draining water. Failure to do so could result in property damage,

personal injury, or death.

CAUTION

It is very important that the condensate piping be no smaller than

¾”. To prevent sagging and maintain pitch, condensate piping

should be supported with pipe supports, and pitched ¼” per foot

to allow for proper drainage.

The condensate line must remain unobstructed, allowing free

ow of condensate. If condensate freezes in the line, or if line is

obstructed in any other manner, condensate can exit from the tee,

resulting in potential water damage to property.

D. Replacing Components

At any point in time over the boiler’s service life it may be necessary

to replace boiler components. If the boiler displays an error message,

determine its cause and possible remedies.

If the remedy is replacement of a component, ensure:

1. That the boiler is powered OFF. Press the ON/OFF button to turn

the boiler o. Then turn the main electrical power to the boiler o

at the circuit breaker.

2. The boiler electrical connection is connected properly. A loose

electrical connection could the root cause of problems.

3. The front cover has been removed.

4. The main shuto gas valve is closed.

5. All water valves to and from the boiler (supply, return, inlet, outlet)

are closed.

6. If necessary, the water has been drained from the boiler and/or

appropriate circuit.

7. No water can get into the display / control panel.

Figure 88 - Removing the DHW Filter

Failure to replace a damaged sealing ring will result in exhaust

gas leaks, substantial property damage, severe personal injury, or

death.

DANGER

5. Proceed in the reverse order to reinstall the components.

Replacing the Burner

1. Remove the front cover and pivot the electronic housing following

the instructions described in Removing the Cabinet Cover and

Inspecting the Boiler.

2. Remove the combustion assembly as described in Cleaning the

Heat Exchanger Combustion Chamber.

3. Remove, inspect, and replace the burner as described in Checking

the Burner.

4. Replace all damaged seals that are damaged or showing signs of

wear.

Loading...

Loading...