TFTN 085-199 Installation and Operation Manual

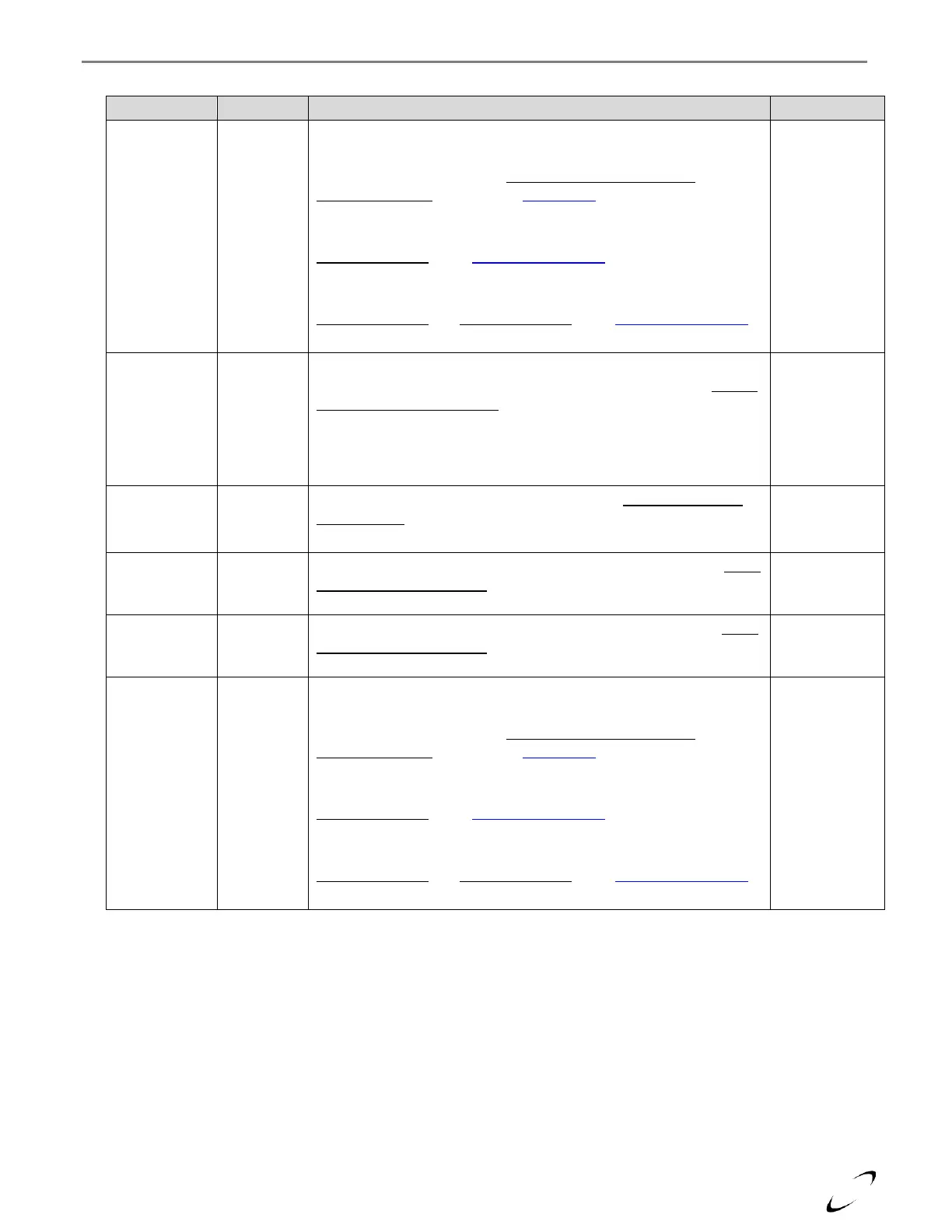

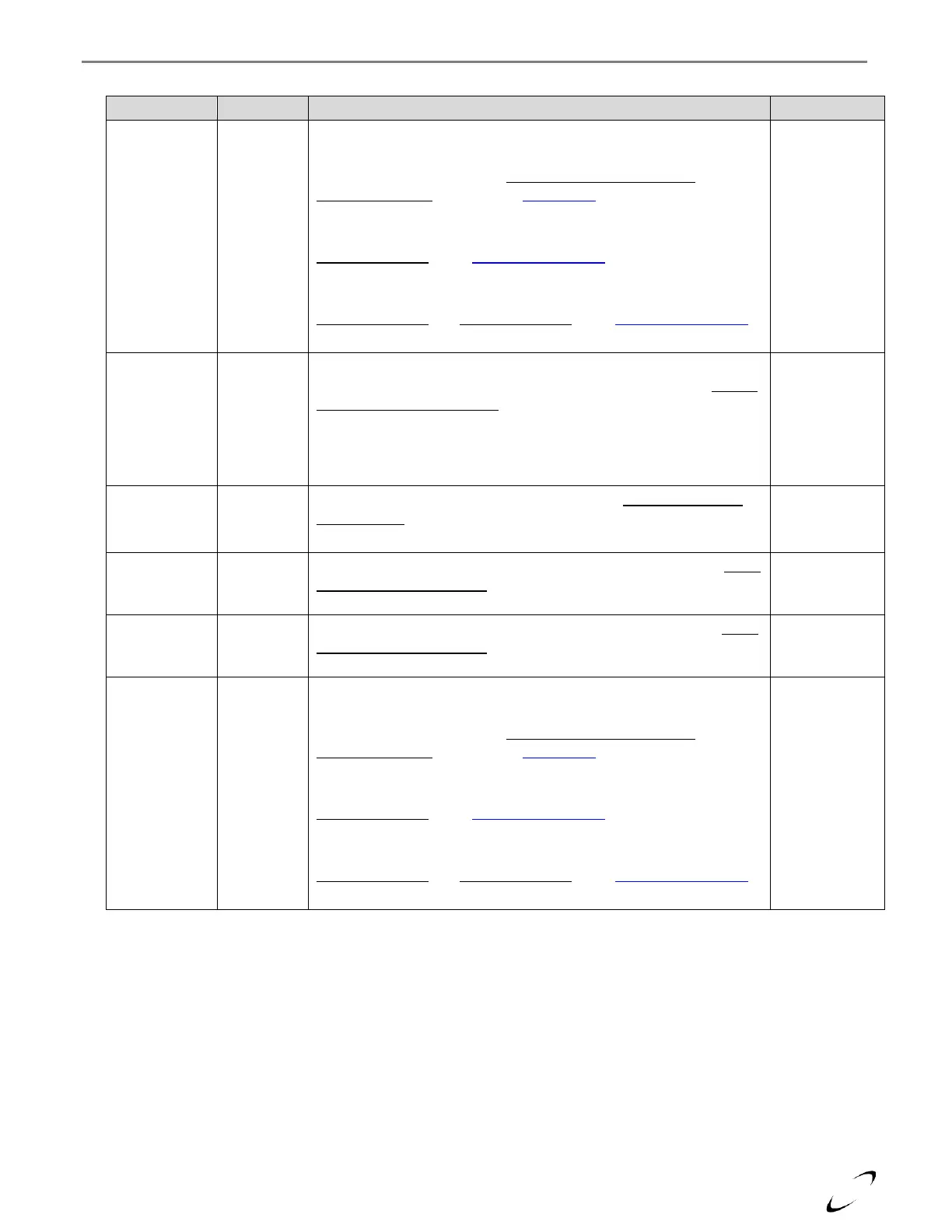

Table 16-10 Pump Control Settings (…Continued)

Auxiliary

Pump 1

Selection

Sets the functionality of output AUX1 PUMP.

System Pump – powers during CH demands. Will also power during

Downstream IWH demands if System Pump Activation Logic, in the

Advanced Settings screen of the DHW Setup menu, is set as Always

Active.

DHW Recirc – powers during DHW Recirc demands; see setting

Auxiliary Sensor 2 in the Sensor Configuration menu for setup of a

DHW Recirc sensor.

Buffer Tank – powers during Buffer Tank demands; see settings

Auxiliary Sensor 1 and Auxiliary Sensor 2 in the Sensor Configuration

menu for setup of a Buffer Tank sensor.

Boiler Pump

Speed Control

Signal

Sets the type of signal that the boiler will output to drive the speed of

a variable speed boiler pump to achieve a delta-T equal to the Delta-T

Target - Pump Speed Control setting.

0-10V – connect to VAR. PUMP terminals "+" and "return" (in arrow).

PWM – connect to VAR. PUMP terminals "-", "return" and "out" (out

arrow).

Delta-T Target

– Pump Speed

Control

Sets the delta-T target for the boiler when using Boiler Pump Speed

Control Signal to control the speed of a variable speed boiler pump.

(Range = 5-45°F)

Sets the maximum control signal to the boiler pump when using Boiler

Pump Speed Control Signal to control the speed of a variable speed

boiler pump. (Range = MinimumPumpSpeed-100%)

Sets the minimum control signal to the boiler pump when using Boiler

Pump Speed Control Signal to control the speed of a variable speed

boiler pump. (Range = 20-MaximumPumpSpeed)

Auxiliary

Pump 2

Selection

Sets the functionality of output AUX2 PUMP.

System Pump – powers during CH demands. Will also power during

Downstream IWH demands if System Pump Activation Logic, in the

Advanced Settings screen of the DHW Setup menu, is set as Always

Active.

DHW Recirc – powers during DHW Recirc demands; see setting

Auxiliary Sensor 2 in the Sensor Configuration menu for setup of a

DHW Recirc sensor.

Buffer Tank – powers during Buffer Tank demands; see settings

Auxiliary Sensor 1 and Auxiliary Sensor 2 in the Sensor Configuration

menu for setup of a Buffer Tank sensor.

16.3.2.5 BMS Control

Access the BMS Control screen to configure the boiler to accept a 0-10V signal to control the burner firing rate or

temperature setting from an external device.

Note: BMS Control is only applicable for CH demands – not DHW demands. For cascade systems, the external 0-10V is

applied to the Manager boiler for control of the complete cascade for CH demands.

Loading...

Loading...