3. ENGINE

3-

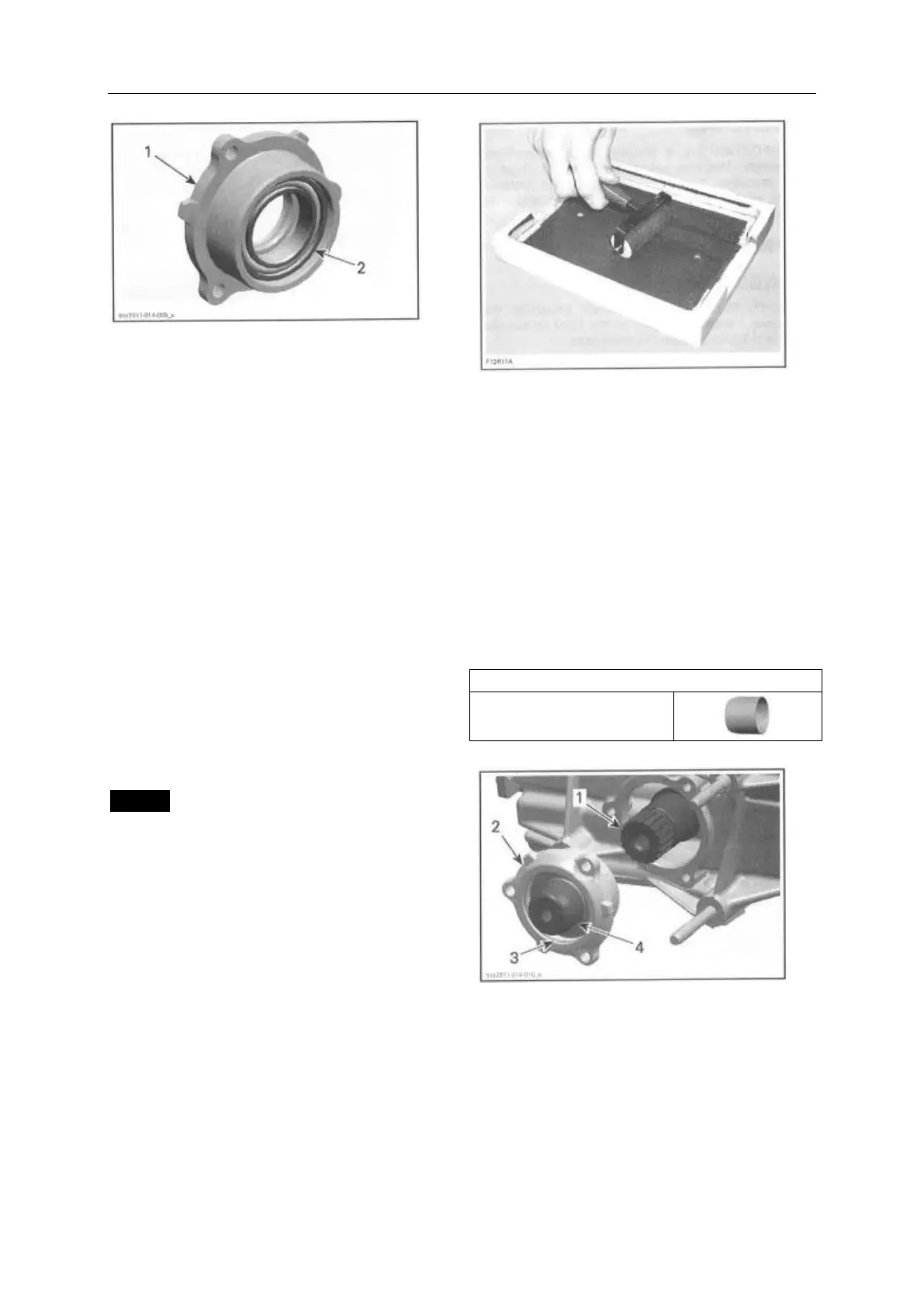

1. Bearing cover

2. Drive shaft bearing

Check drive shaft for cracks, bend, pitting or other

visible damages.

Check drive shaft splines for wear or damages.

Check oil seal running surface of the drive shaft

for scratches. Replace if necessary.

Engine Drive Shaft Installation

The installation is the reverse of removal

procedure. Pay attention to the following details.

Clean all metal components in solvent.

Crankcase surfaces and bearing covers are best

cleaned using a combination of LOCTITE

CHISEL (GASKET REMOVER) (P/N413 708

500) and a brass brush. Brush a first pass in one

direction then make the final brushing

perpendicularly (90°) to the first pass.

NOTICE Do not wipe with rags. Use a new clean

hand towel only.

Use a suitable installer for installing bearings.

Use LOCTITE5910 (P/N293800 081) on mating

Su faces.

IMPORTANT: When beginning the application of

the bearing cover sealant, the assembly and the

first torquing should be done within10 minutes.

it is suggested to have all you need on hand to save

time.

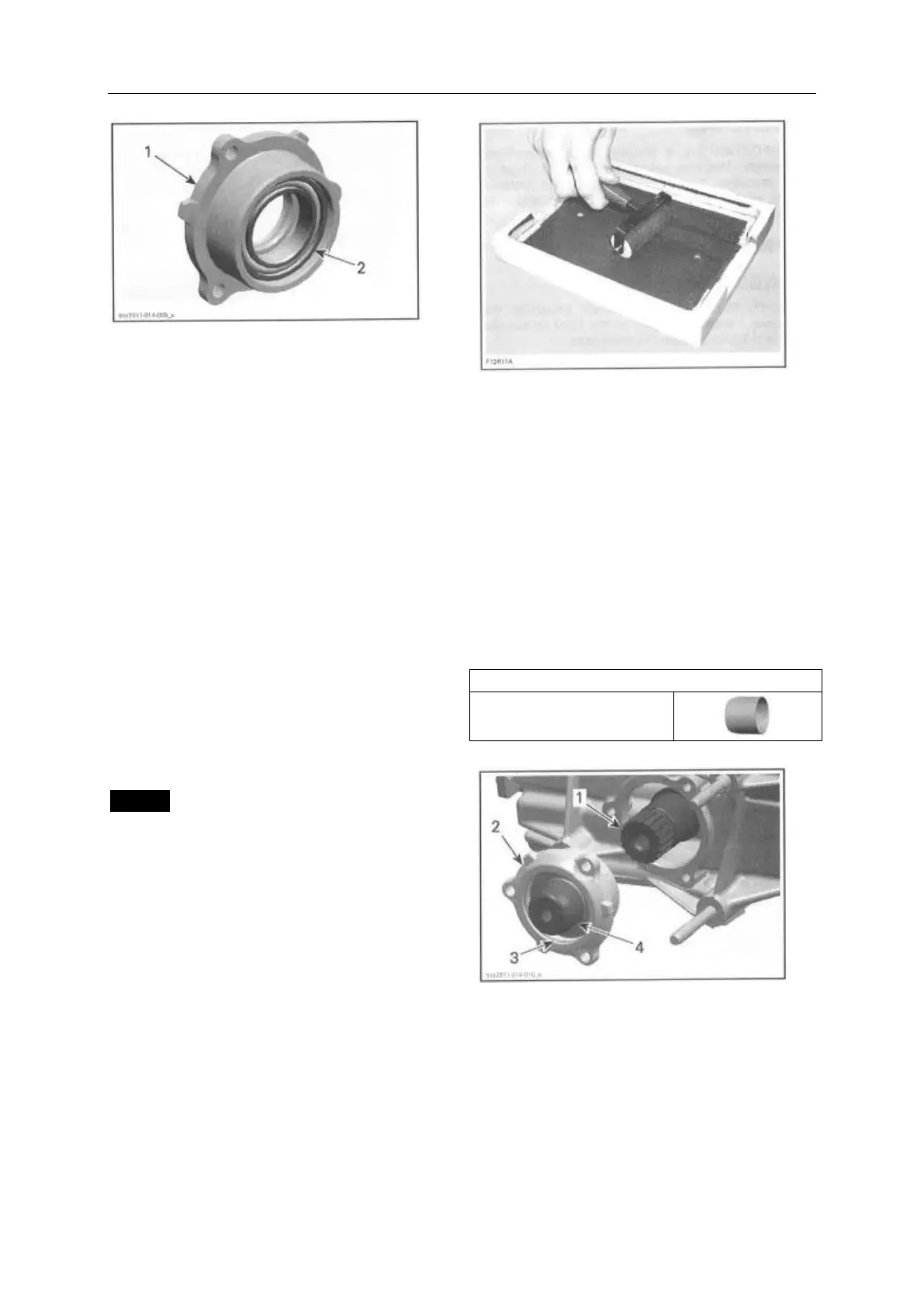

Use a plexiglass plate and apply some sealant on it.

Use a soft rubber roller50mm-75mm (2in_ 3in),

available in arts products suppliers for printing,

and rol1 the sealant to get a thin uniform coat on

the plate (spread as necessary). When ready, apply

the sealant on bearing cover surfaces.

Do not apply in excess as it will spread out inside

crankcase.

NOTE: It is recommended to apply this specific

sealant as described here to get a uniform

application without lumps. If you do not use the

roller method, you may use your finger to

uniformly distribute the sealant (using a finger

w1ll not affect the adhesion).

Rear Bearing Cover Installation

For bearing cover installation on gearbox side,

protect the oil seal to avoid damaging the sealing

lip.

1. Drive shaft

2. Bearing cover gearbox side

3. O-ing

4. Protection sleeve

Loading...

Loading...